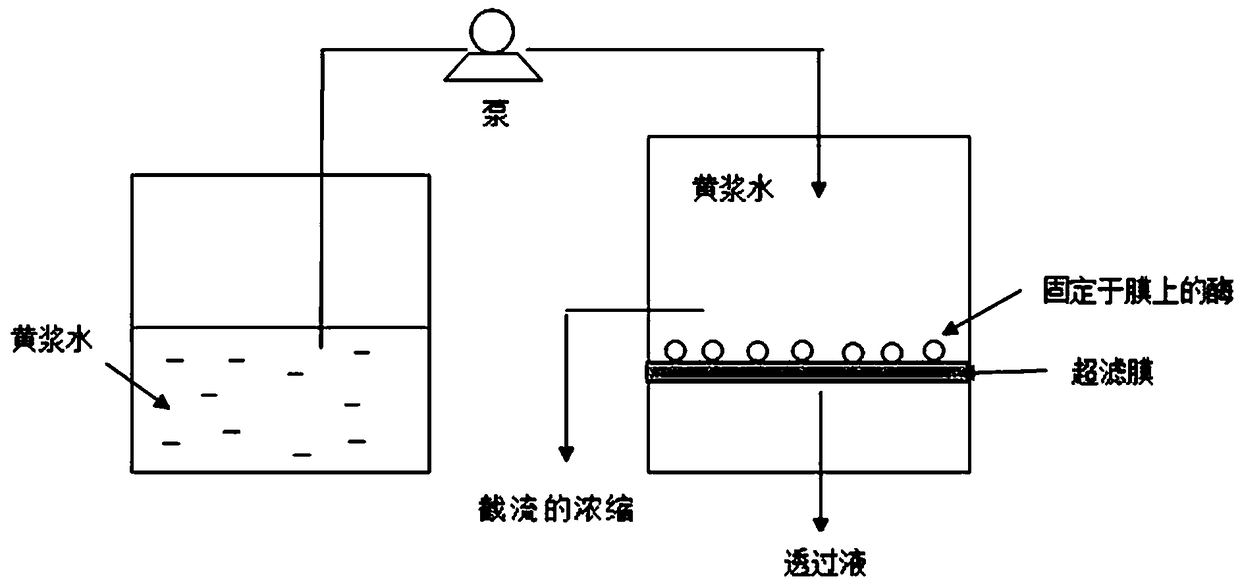

Method for ultrafiltration removal of proteins from yellow serofluid by using enzyme membrane reactor

An enzyme membrane reactor and a technology for yellow slurry water, applied in the field of ultrafiltration de-yellow slurry water protein, filtration de-yellow slurry water protein field, can solve unfavorable enzymes, filter membrane recycling, affect ultrafiltration work efficiency, can not realize circulation Utilize and other problems to achieve the effect of improving cycle utilization, realizing process continuity, and eliminating unfavorable kinetics and thermodynamics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

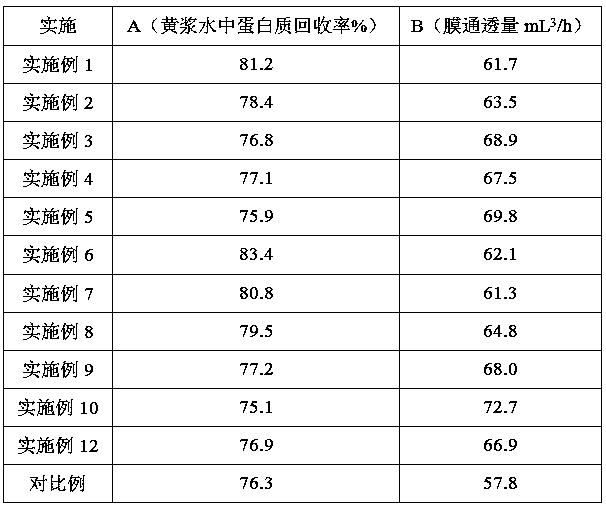

Examples

Embodiment 1

[0045] A method for utilizing an enzyme membrane reactor to ultrafiltrate proteins in deyellowing slurry water, comprising the steps of:

[0046] A. Raw material pretreatment

[0047] Coarse filtration: collect the yellow pulp water produced in the process of tofu and product processing, and filter it with a plate and frame filter to obtain a coarse filtrate for use;

[0048] pH adjustment: heat the obtained crude filtrate to 80°C, keep it for 20 minutes, then cool it to 40°C, adjust the pH value to 5 with acid, and obtain the pretreatment liquid for later use;

[0049] B. Preparation of ultrafiltration enzyme membrane

[0050] Put the membrane into the mixed solution I, soak it at room temperature for 2 hours, and then wash it once with distilled water to obtain the membrane I; the mixed solution I includes 8% methacrylic acid, 2‰ potassium persulfate and 1‰ potassium pyrosulfite ;

[0051] Put the obtained membrane I into the mixed solution II, soak it at 4°C for 1.5h, ...

Embodiment 2

[0056] A method for utilizing an enzyme membrane reactor to ultrafiltrate proteins in deyellowing slurry water, comprising the steps of:

[0057] A. Raw material pretreatment

[0058] Coarse filtration: collect the yellow pulp water produced in the process of tofu and product processing, and filter it with a plate and frame filter to obtain a coarse filtrate for use;

[0059] pH adjustment: heat the obtained crude filtrate to 82°C, keep it for 23 minutes, then cool it to 44°C, adjust the pH value to 5.2 with acid, and obtain the pretreatment liquid for later use;

[0060] B. Preparation of ultrafiltration enzyme membrane

[0061] Put the membrane into the mixed solution I, soak it at room temperature for 2.4 hours, and then wash it once with distilled water to obtain the membrane I; the mixed solution I includes 8.3% methacrylic acid, 2.2‰ potassium persulfate and 1.4‰ pyrosulfite Potassium;

[0062] Put the obtained membrane I into the mixed solution II, soak it at 4°C f...

Embodiment 3

[0067] A method for utilizing an enzyme membrane reactor to ultrafiltrate proteins in deyellowing slurry water, comprising the steps of:

[0068] A. Raw material pretreatment

[0069] Coarse filtration: collect the yellow pulp water produced in the process of tofu and product processing, and filter it with a plate and frame filter to obtain a coarse filtrate for use;

[0070] pH adjustment: heat the obtained crude filtrate to 85°C, keep it for 25 minutes, then cool it to 45°C, adjust the pH value to 5.5 with acid, and obtain the pretreatment liquid for later use;

[0071] B. Preparation of ultrafiltration enzyme membrane

[0072] Put the membrane into the mixed solution I, soak it at room temperature for 2.5 hours, and then wash it twice with distilled water to obtain the membrane I; the mixed solution I includes 8.5% methacrylic acid, 2.5‰ potassium persulfate and 1.5‰ pyrosulfite Potassium;

[0073] Put the obtained membrane I into the mixed solution II, soak it at 4°C ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com