Direct injection gas nozzle and engine and power system of direct injection gas nozzle

A technology of gas nozzles and engines, which is applied to gaseous engine fuels, engine components, combustion engines, etc., can solve problems such as ablation, and achieve the effects of small unit volume, light weight, and high energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

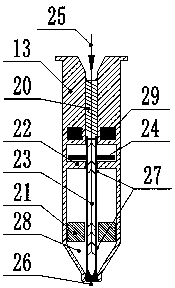

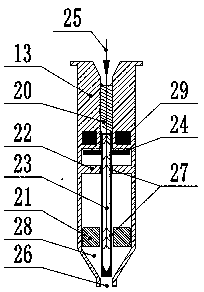

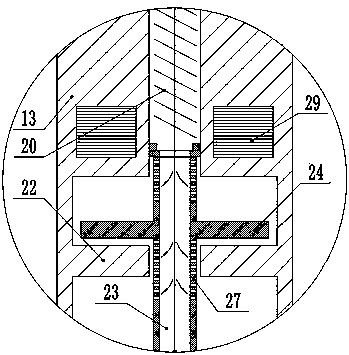

[0041] Gas direct injection nozzle of the present invention such as Figure 1 ~ Figure 4 As shown, the hydrogen gas nozzle 13 is composed of a housing, a gas collection chamber 28, a nozzle orifice 26 and a gas channel 25, and the gas channel passes through the gas collection chamber to communicate with the nozzle orifice. The upper part of the gas passage is equipped with a spring 20, and the lower part is equipped with a hollow plunger 23, and the wall of the hollow plunger tube of the gas collection chamber section of the gas passage is provided with a plunger nozzle 27. The upper part of the gas collection chamber is provided with a gas bearing 22 on the plunger, and the lower part is provided with a gas bearing 21 under the plunger. The device is installed in conjunction with the electromagnetic coil. Through the attraction and release of the plunger stopper by the electromagnetic coil, the hollow plunger moves up and down to realize the opening and closing control of th...

Embodiment 2

[0051] Another embodiment of the present invention is as Figure 7 As shown, the hydrogen fuel engine is a two-stroke engine, including a cylinder 5, a cylinder head 40, a crankcase 35 and a water pan 6, the cylinder head is provided with an oxygen nozzle 34 and a spark plug 36, and the cylinder wall is provided with an air inlet 37 and an exhaust hole 41. A crankshaft 45 is arranged in the crankcase, and a piston 43 is arranged in the cylinder, and the piston is connected with the crankshaft through a connecting rod 44 . The structure of the oxygen nozzle 34 is the same as that of the gas direct injection nozzle in the first embodiment.

[0052] The operation mode of the oxygen direct injection pure hydrogen combustion internal combustion engine power system of the present invention is: 4MPa hydrogen enters the cylinder of the hydrogen fuel engine through the air intake hole, and is ignited by contact with oxygen through piston compression. 2MPa high-pressure oxygen is inje...

Embodiment 3

[0057] The third embodiment of the present invention is as Figure 6 As shown, the hydrogen fuel engine is a four-stroke engine including cylinder 5, water pan 6 and crankcase 35, and the top of the cylinder block is provided with oxygen nozzle 34, spark plug 36, air inlet 38 and exhaust hole 41, and crankcase 35 is provided with Crankshaft 45 is arranged, and in the cylinder body is combustion chamber 46, is provided with piston 43 in the cylinder, and piston is connected with crankshaft 45 by connecting rod 44. The bottom outlet of the water pan 6 of the hydrogen fuel engine is connected to the purification unit, the liquid outlet is connected to the circulating water tank, and the circulating water tank is connected to the water pan 6 through a water supply pipe and a three-way valve. The structure of the oxygen nozzle 34 is the same as that of the gas direct injection nozzle in the first embodiment.

[0058] The operation mode of the oxygen direct injection pure hydrogen ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com