Method for preparing temperature-sensitive film with heat insulation buffer layer structure

A heat-sensitive film and buffer layer technology, applied in the direction of resistors with negative temperature coefficient, resistance manufacturing, non-adjustable metal resistors, etc., can solve the problem of fast response temperature sensing, increasing the heat capacity of sensitive units, Issues such as increased response time of thin film materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

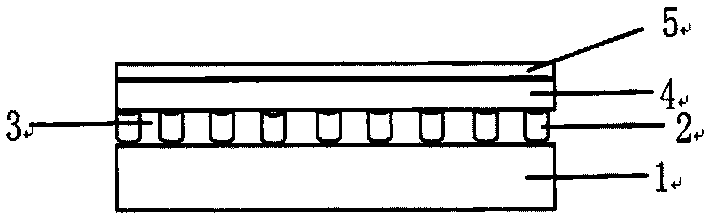

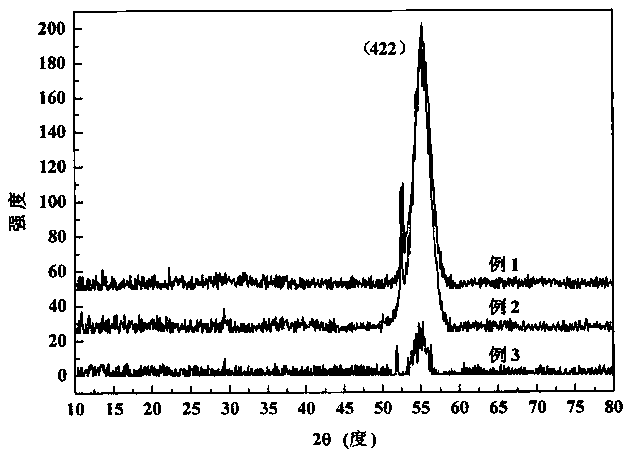

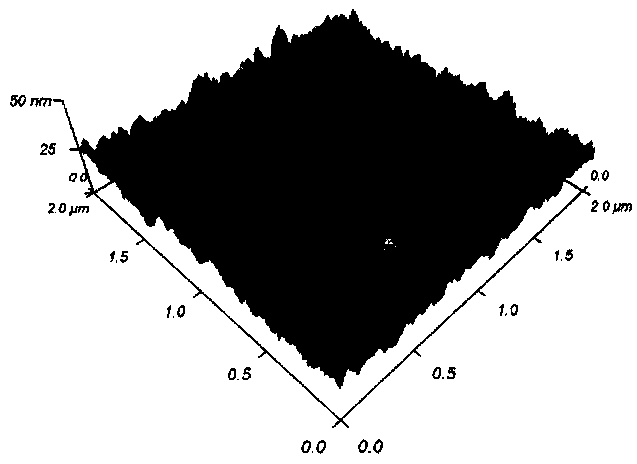

[0018] a. Preparation of thermal insulation buffer layer: firstly, immerse the purchased silicon substrate 1 in acetone, absolute ethanol, and deionized water, and perform ultrasonic washing for 3 times, each washing time is 5 minutes, take out the silicon substrate 1, and use high-purity Dry the surface of the silicon substrate 1 with nitrogen gas, then make masks of various shapes on the surface of the silicon substrate 1, put the silicon substrate 1 into the cavity of the electron beam evaporation equipment, and place the mask hollowed out on the surface of the silicon substrate 1 Growing the silicon material 2 to form a silicon column, by adjusting the voltage 1, the evaporation time is 5 minutes, controlling the height of the silicon material 2 of the silicon column to be 10nm, and utilizing the air stored in the hole 3 in the gap of the silicon column to realize thermal insulation;

[0019] b. Preparation of silicon dioxide insulating layer: put the silicon substrate 1 pr...

Embodiment 2

[0022] a. Preparation of thermal insulation buffer layer: firstly, immerse the purchased silicon substrate 1 in acetone, absolute ethanol, and deionized water, and perform ultrasonic washing 3 times for 10 minutes each time. Dry the surface of the silicon substrate 1 with nitrogen gas, then make masks of various shapes on the surface of the silicon substrate 1, put the silicon substrate 1 into the cavity of the electron beam evaporation equipment, and place the mask hollowed out on the surface of the silicon substrate 1 Growing silicon material 2 to form silicon balls, controlling the height of the silicon material 2 of the silicon balls to 200 μm by adjusting the voltage of 2 kV and evaporation time of 60 minutes, using the air stored in the holes 3 in the gaps of the silicon balls to realize thermal insulation;

[0023] b. Preparation of silicon dioxide insulating layer: put the silicon substrate 1 prepared in step a into a thermal oxidation furnace at a temperature of 1050°C...

Embodiment 3

[0026] a. Preparation of the thermal insulation buffer layer: firstly, the purchased silicon substrate 1 was immersed in acetone, absolute ethanol, and deionized water in sequence, and ultrasonically washed 3 times, each washing time was 8 minutes, the silicon substrate 1 was taken out, and the Dry the surface of the silicon substrate 1 with nitrogen gas, then make masks of various shapes on the surface of the silicon substrate 1, put the silicon substrate 1 into the cavity of the electron beam evaporation equipment, and place the mask hollowed out on the surface of the silicon substrate 1 Growing silicon material 2 to form silicon rods, controlling the height of the silicon material 2 of the silicon rods to be 150 μm by adjusting the voltage to 1.5kV and evaporating for 20 minutes, and utilizing the air stored in the holes 3 in the gaps of the silicon rods to realize thermal insulation;

[0027] b. Preparation of silicon dioxide insulating layer: put the silicon substrate 1 pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com