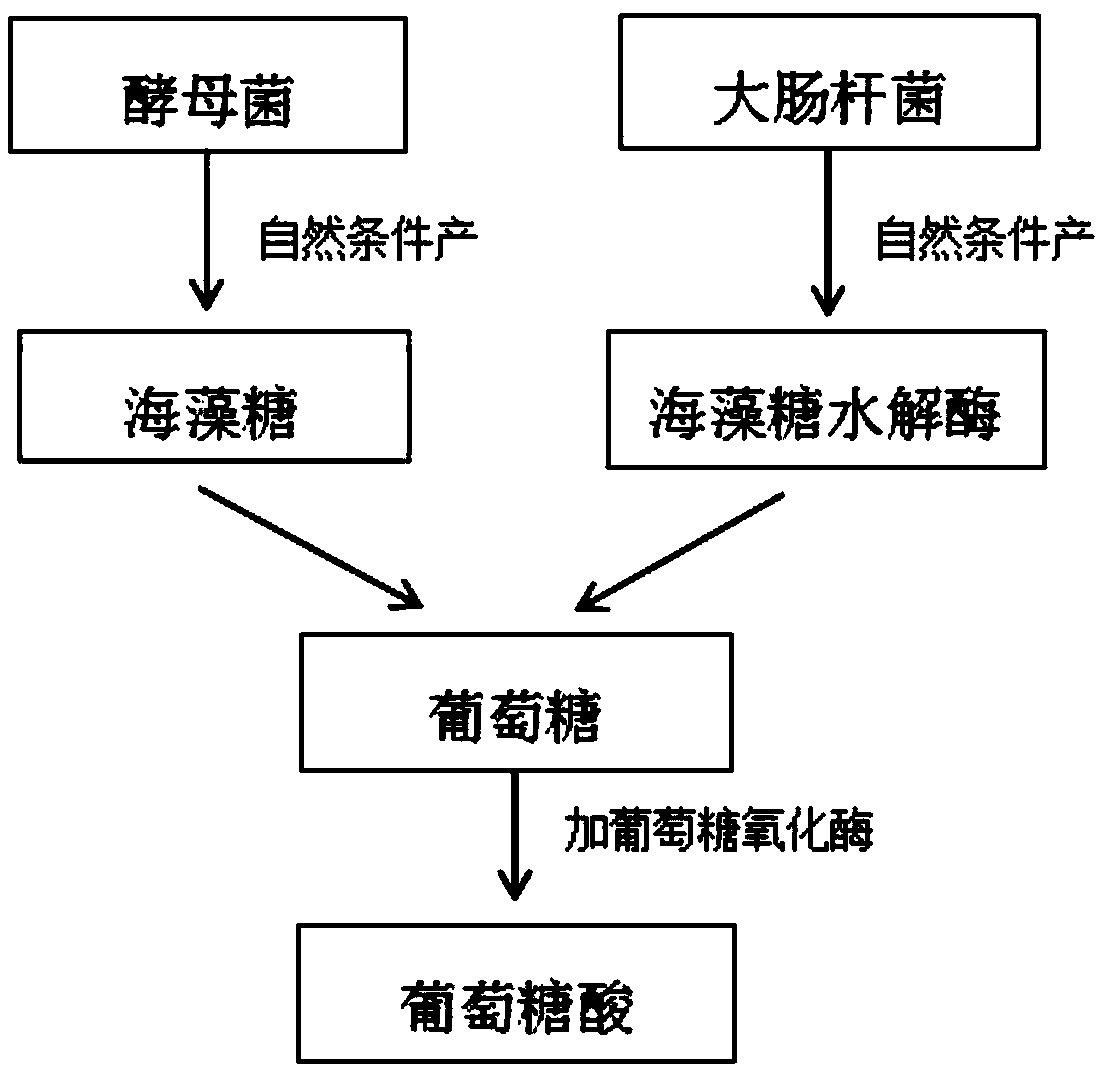

Method for preparing biofuel cell by using trehalose produced by yeast

A biofuel cell and trehalose technology, applied in the fields of chemistry and biology, can solve single problems, achieve the effects of avoiding environmental pollution, strong growth ability, and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

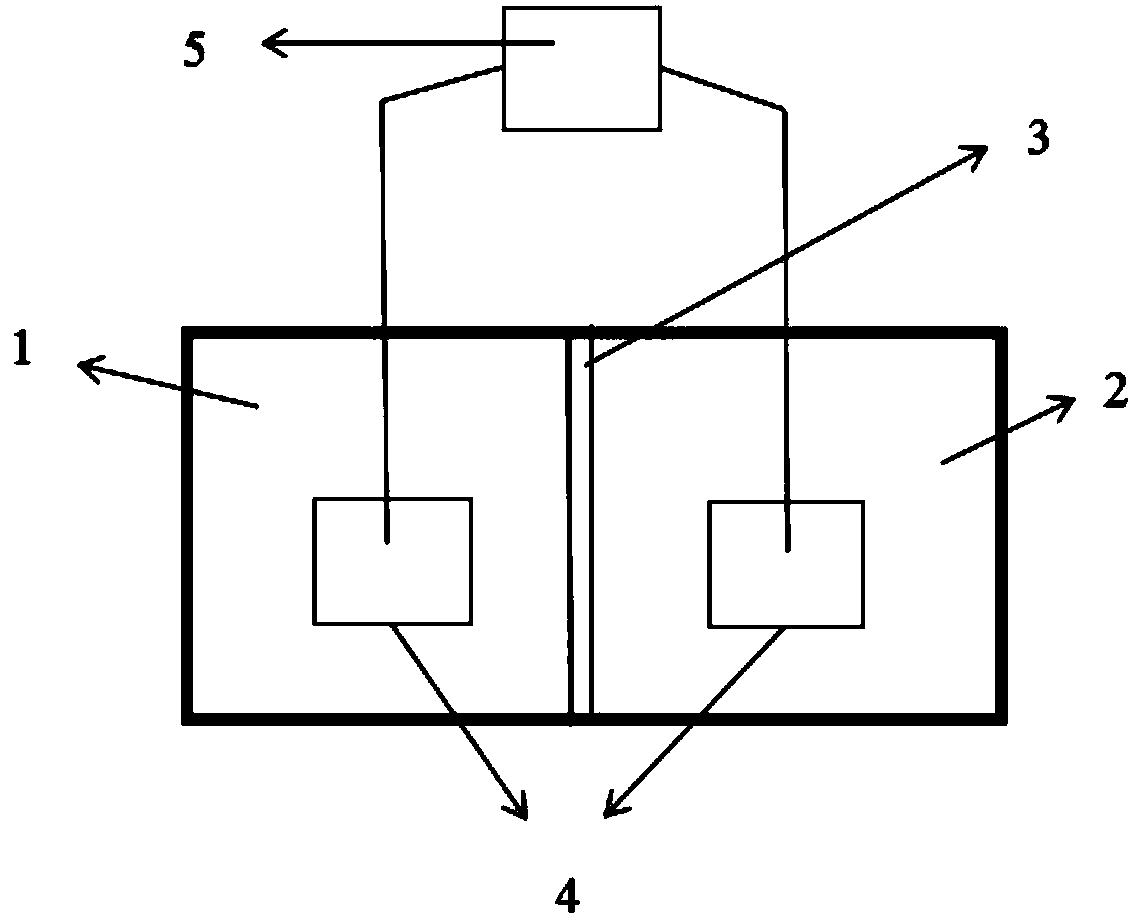

Method used

Image

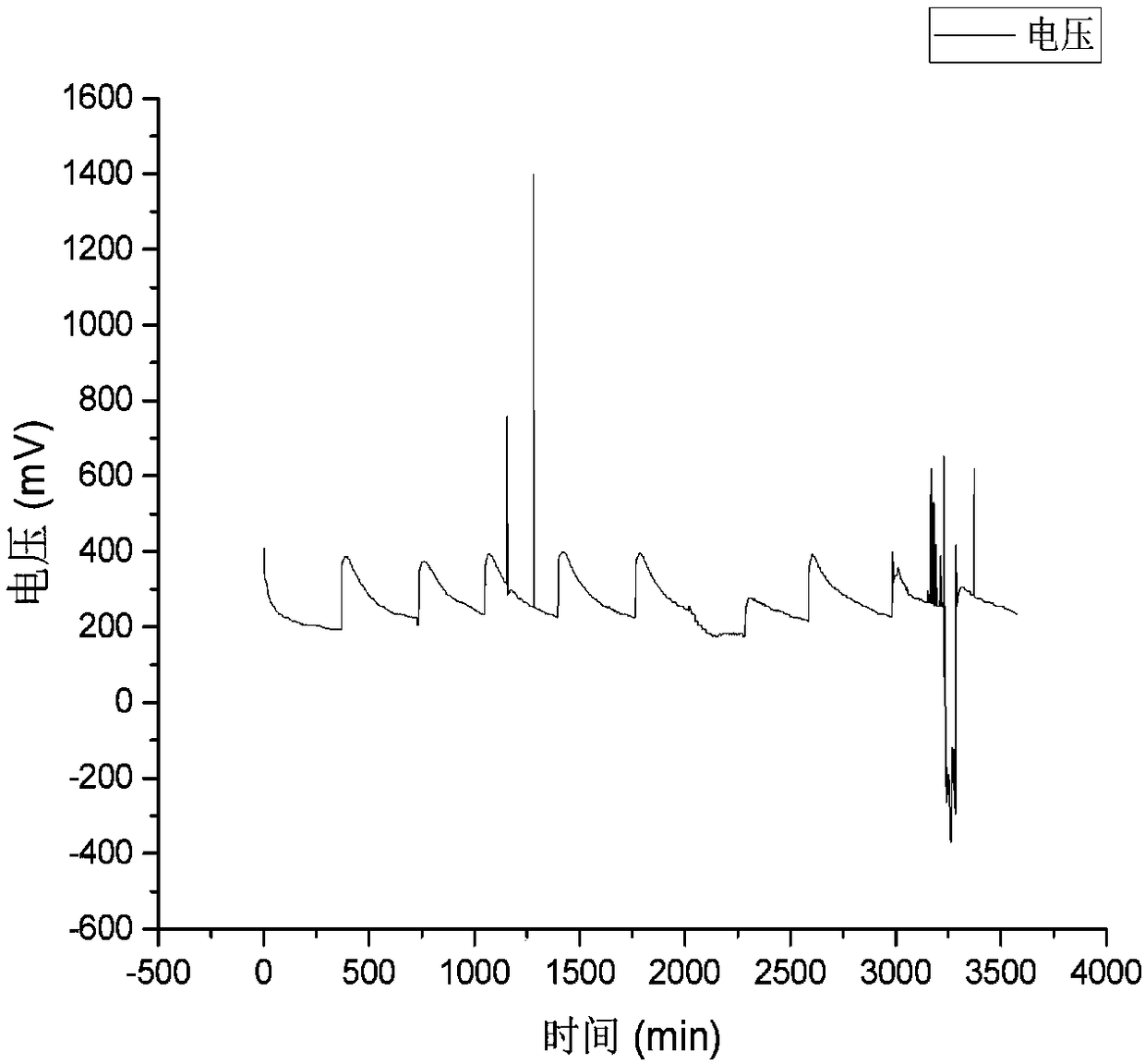

Examples

Embodiment 1

[0037] (1) Weigh 6.1mg of 222 u / mg glucose oxidase solid into a 150mL Erlenmeyer flask, add distilled water and stir to prepare 50mL of 27 u / mL glucose oxidase solution, place a blank carbon felt electrode (surface area 1.5cm× 1.5cm) into the solution, soak at 200r / min 37°C for 12 hours, take it out, and refrigerate at -4°C for later use;

[0038] (2) Inoculate 2 mL of yeast cryopreservation liquid into a 250 mL Erlenmeyer flask filled with 50 mL of YPD culture liquid, shake the flask at 200 r / min 28-30°C for 24 h, and obtain yeast fermentation liquid for later use;

[0039] After about 12 h of yeast fermentation, inoculate 2 mL of E. coli frozen stock solution into a 250 mL Erlenmeyer flask filled with 50 mL of LB culture liquid, and shake the flask at 200 r / min at 37°C for 12 h to obtain E. coli fermentation liquid. ;

[0040] Centrifuge the yeast fermentation broth and E. coli fermentation broth at 2800rpm for 10 minutes respectively, wash twice with PBS, and then centrifu...

Embodiment 2

[0045] (1) Weigh 6.1mg of 222 u / mg glucose oxidase solid into a 150mL Erlenmeyer flask, add distilled water and stir to prepare 50mL of 27 u / mL glucose oxidase solution, place a blank carbon felt electrode (surface area 1.5cm× 1.5cm) into the solution, soak at 200r / min 37°C for 12 hours, take it out, and refrigerate at -4°C for later use;

[0046] (2) Inoculate 2mL of yeast cryopreservation liquid into a 250mL Erlenmeyer flask filled with 50mL of YPD culture liquid, shake the flask at 200r / min 28-30°C for 24 hours, and obtain a yeast fermentation liquid for later use;

[0047] After about 12 h of yeast fermentation, inoculate 2 mL of E. coli frozen stock solution into a 250 mL Erlenmeyer flask filled with 50 mL of LB culture liquid, and shake the flask at 200 r / min at 37°C for 12 h to obtain E. coli fermentation liquid. ;

[0048] Centrifuge the yeast fermentation broth and E. coli fermentation broth at 2800rpm for 10 minutes respectively, wash twice with PBS, and then centri...

Embodiment 3

[0053] (1) Weigh 6.1mg of 222 u / mg glucose oxidase solid into a 150mL Erlenmeyer flask, add distilled water and stir to prepare 50mL of 27 u / mL glucose oxidase solution, place a blank carbon felt electrode (surface area 1.5cm× 1.5cm) into the solution, soaked at 200r / min 37°C for 12 hours, took it out, and refrigerated at -4°C for later use.

[0054] (2) Inoculate 2mL of yeast cryopreservation liquid into a 250mL Erlenmeyer flask filled with 50mL of YPD culture liquid, shake the flask at 200r / min28-30℃ for 24 hours to obtain yeast fermentation liquid, and set aside;

[0055] After about 12 h of yeast fermentation, inoculate 2 mL of E. coli frozen stock solution into a 250 mL Erlenmeyer flask filled with 50 mL of LB culture liquid, and shake the flask at 200 r / min at 37°C for 12 h to obtain E. coli fermentation liquid. ;

[0056] Centrifuge the yeast fermentation broth and E. coli fermentation broth at 2800rpm for 10 minutes respectively, wash twice with PBS, and then centrifu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com