Additive for lead-acid storage battery gelled electrolyte and preparation method and application thereof

A colloidal electrolyte, lead-acid battery technology, applied in lead-acid batteries, acid electrolytes, secondary batteries, etc., can solve the problems of human health and ecological environment hazards, poor stability of lead-acid batteries, and low cycle life, etc. Effects of improved chemical stability and corrosion resistance, increased actual surface area, and improved cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

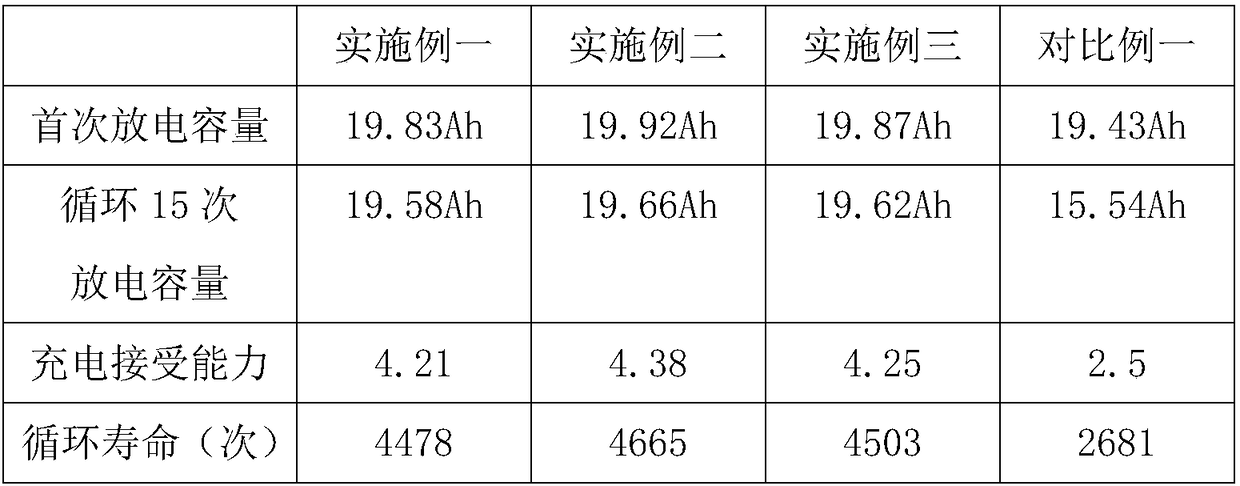

Examples

Embodiment 1

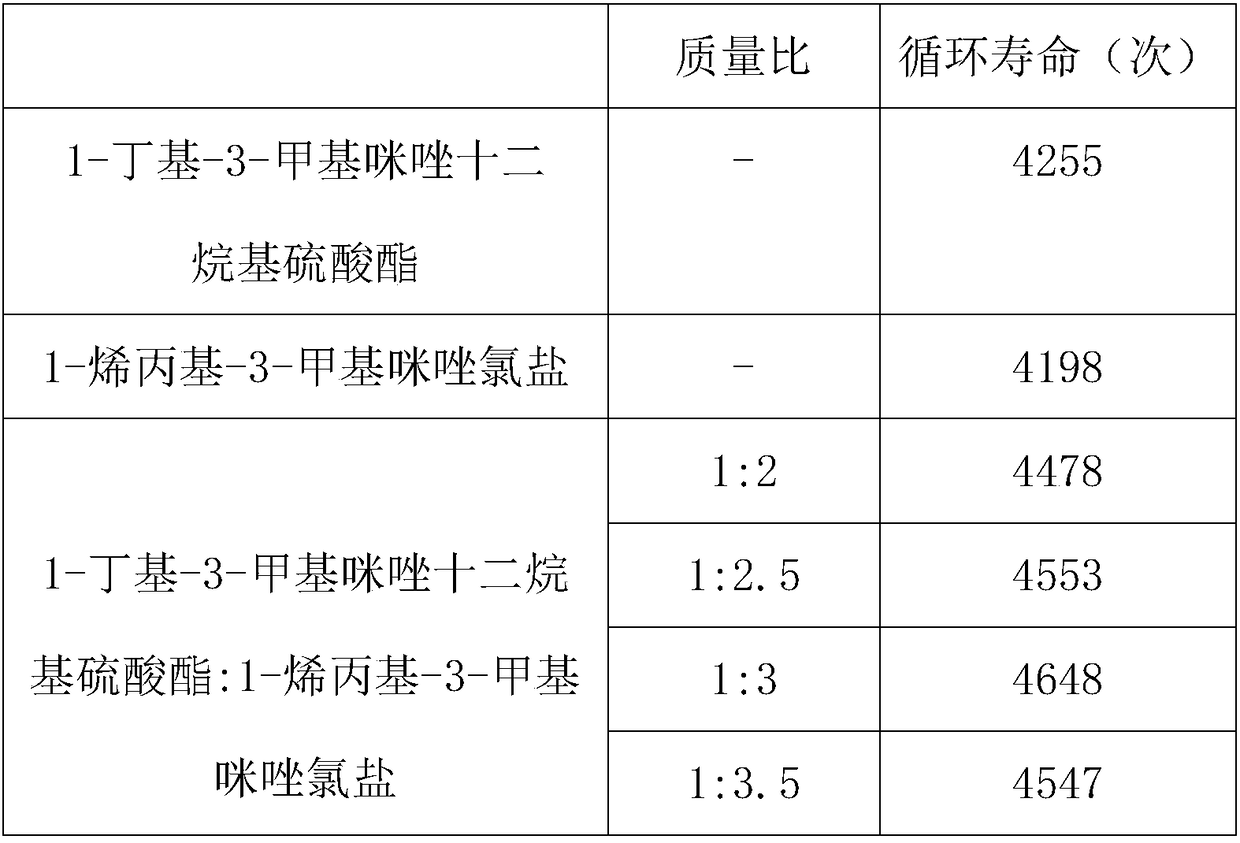

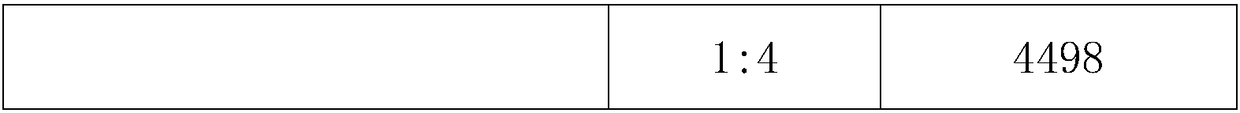

[0017] A kind of lead-acid accumulator colloidal electrolyte additive that the present invention proposes, comprises the raw material of following weight portion: 1 part of 1-butyl-3-methylimidazolium dodecyl sulfate, 1-allyl-3-methyl 2 parts of imidazolium chloride salt, 2 parts of nano-boron oxide, 5 parts of titanium dioxide, 8 parts of nano-titanium diboride, 1 part of graphene, 8 parts of acetylene black, 4 parts of sulfate, 7 parts of grease, polyacrylamide 1 part, 2 parts of sulfuric acid, 28 parts of distilled water; the concentration of the sulfuric acid solution is 1.02g / cm 3 .

[0018] Its preparation method comprises the following steps:

[0019] S1. Add the specific gravity of 1-allyl-3-methylimidazolium chloride, nano-boron oxide, sulfate, lubricating grease and distilled water into the agitator, stir and mix evenly at a speed of 450r / min to obtain Mixture A;

[0020] S2. Add the specific gravity of titanium oxide, nano-titanium diboride, graphene and acetylen...

Embodiment 2

[0023] A kind of lead-acid accumulator colloidal electrolyte additive that the present invention proposes, comprises the raw material of following weight portion: 1-butyl-3-methylimidazolium lauryl sulfate 3 parts, 1-allyl-3-methyl 10 parts of imidazolium chloride salt, 5 parts of nano-boron oxide, 7 parts of titanium dioxide, 12 parts of nano-titanium diboride, 4 parts of graphene, 4 parts of acetylene black, 7 parts of sulfate, 10 parts of grease, polyacrylamide 2 parts, 5 parts of sulfuric acid, 32 parts of distilled water; the concentration of sulfuric acid solution is 1.10g / cm 3 .

[0024] Its preparation method comprises the following steps:

[0025] S1. Add the specific gravity of 1-allyl-3-methylimidazolium chloride, nano-boron oxide, sulfate, lubricating grease and distilled water into the agitator, stir and mix evenly at a speed of 550r / min to obtain Mixture A;

[0026] S2. Add the specific gravity of titanium oxide, nano-titanium diboride, graphene and acetylene ...

Embodiment 3

[0029] A kind of additive for colloidal electrolyte of lead-acid storage battery that the present invention proposes, comprises the raw material of following weight portion: 5 parts of 1-butyl-3-methylimidazolium lauryl sulfates, 1-allyl-3-methyl 20 parts of imidazolium chloride salt, 7 parts of nano-boron oxide, 9 parts of titanium dioxide, 15 parts of nano-titanium diboride, 8 parts of graphene, 1 part of acetylene black, 10 parts of sulfate, 13 parts of grease, polyacrylamide 3 parts, 8 parts of sulfuric acid, 35 parts of distilled water; the concentration of the sulfuric acid solution is 1.17g / cm 3 .

[0030] Its preparation method comprises the following steps:

[0031] S1. Add the specific gravity of 1-allyl-3-methylimidazolium chloride, nano boron oxide, sulfate, lubricating grease and distilled water into the agitator, stir and mix evenly at a speed of 650r / min to obtain Mixture A;

[0032]S2. Add the specific gravity of titanium oxide, nano-titanium diboride, graph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com