Acne treatment skin whitening cream and preparation method thereof

A technology for whitening cream and acne removal, which is applied in the directions of pharmaceutical formulations, cosmetic preparations, cosmetic preparations, etc., can solve the problems of affecting the appearance, not easy to eliminate acne, secondary skin damage, etc., and reduce the permeability of blood vessels. , Speed up the time of acne removal, reduce the effect of inflammatory reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

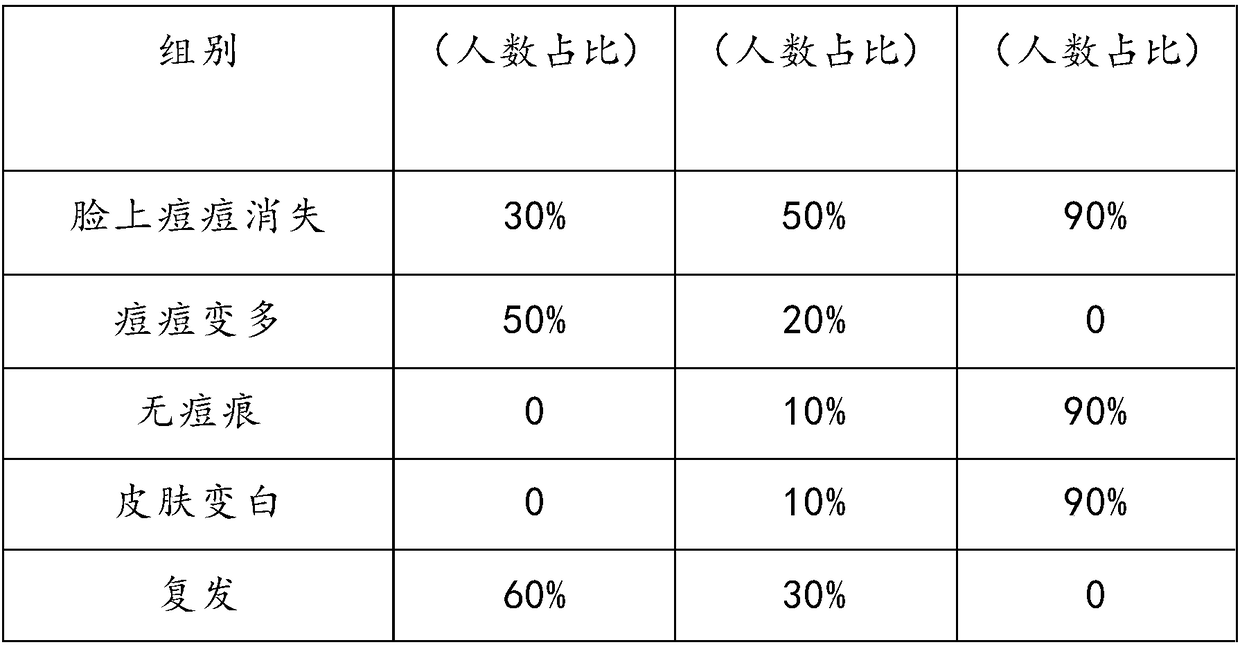

Examples

Embodiment 1

[0012] An acne-removing and whitening cream, which is made of the following materials in proportion by weight: 30 parts of bovine heart fruit, 10 parts of Lai grape, 10 parts of prune, 10 parts of kelp, 10 parts of Shanzi mushroom, 10 parts of bupleurum, 8 parts of cottongrass, 8 parts of yacon, 6 parts of kudiding, 6 parts of chrysanthemum, 6 parts of peach tree leaves, 5 parts of paulownia flower, 5 parts of mangosteen bark, 16 parts of butylene glycol and 8 parts of propylene glycol fatty acid ester.

[0013] A preparation method for acne-removing and whitening cream, comprising the following steps:

[0014] 1) Take 10 parts of kelp, 10 parts of bupleurum, 8 parts of cotton grass, 6 parts of kudiding and 6 parts of ground ear grass, wash and dry them, put them in the oven, and bake them at 60°C for 7 minutes , and then increase the temperature to 120°C, and bake for 10 minutes to prepare the baked dry material for later use;

[0015] 2) Use a pulverizer to crush the dry ba...

Embodiment 2

[0024] An acne-removing and whitening cream, which is made of the following materials in proportion by weight: 20 parts of bovine heart fruit, 20 parts of Lai grape, 18 parts of prune, 16 parts of kelp, 16 parts of Shanzi mushroom, 14 parts of bupleurum, 12 parts of cotton grass, 10 parts of yacon, 8 parts of kudiding, 8 parts of chrysanthemum, 8 parts of peach tree leaves, 7 parts of paulownia flowers, 7 parts of mangosteen bark, 20 parts of butylene glycol and 12 parts of propylene glycol fatty acid ester.

[0025] A preparation method for acne-removing and whitening cream, comprising the following steps:

[0026] 1) Take 16 parts of kelp, 14 parts of bupleurum, 12 parts of cotton grass, 8 parts of kudiding and 8 parts of ground ear grass, wash and dry them, put them in the oven, and bake them at 50 ℃ for 5 minutes , and then increase the temperature to 100°C, and bake for 6 minutes to prepare the baked dry material for later use;

[0027] 2) Use a pulverizer to crush the d...

Embodiment 3

[0036] An acne-removing and whitening cream, which is made of the following materials in proportion by weight: 25 parts of avocado, 15 parts of Lai grape, 14 parts of prune, 13 parts of kelp, 13 parts of Shanzi mushroom, 12 parts of bupleurum, 10 parts of cotton grass, 9 parts of yacon, 7 parts of kudiding, 7 parts of chrysanthemum, 7 parts of peach tree leaves, 6 parts of paulownia flower, 6 parts of mangosteen bark, 18 parts of butylene glycol and 10 parts of propylene glycol fatty acid ester.

[0037] A preparation method for acne-removing and whitening cream, comprising the following steps:

[0038] 1) Take 13 parts of kelp, 12 parts of bupleurum, 10 parts of cotton grass, 7 parts of kudiding and 7 parts of ground ear grass, wash and dry them, put them in the oven, and bake them at 55°C for 6 minutes , and then increase the temperature to 110°C, and bake for 8 minutes to prepare the baked dry material for later use;

[0039] 2) Use a pulverizer to crush the dry baked mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com