Preparation method of magnetic ferric alginate mesoporous carbon microsphere capable of adsorbing heavy metal elements

A technology for adsorbing heavy metals and alginic acid, which is applied in the fields of alkali metal compounds, chemical instruments and methods, and adsorption water/sewage treatment. It can solve the problems of poor stability of adsorption materials, difficult recovery of heavy metals, and high processing costs, and achieve good thermal stability. , Improve recycling rate, good adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

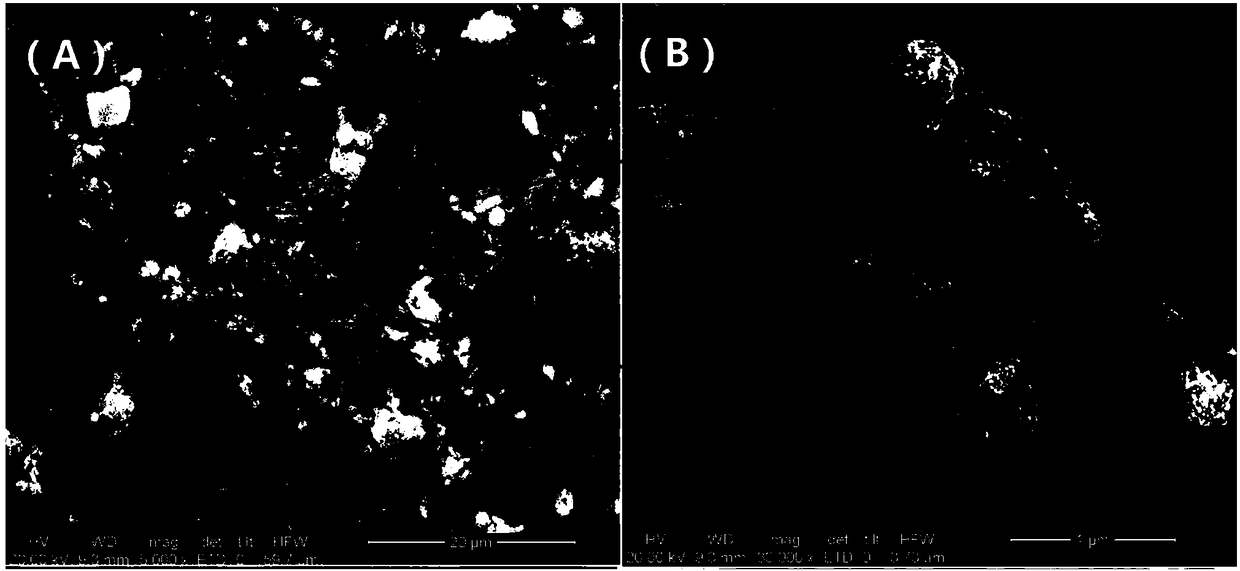

[0025] A preparation method of magnetic iron alginate mesoporous carbon microspheres capable of adsorbing heavy metal elements, comprising the following steps:

[0026] S1), using a ten-thousand-digit balance, weigh 2g of chemically pure grade (viscosity (10g / L) ≥ 0.02Pa·s) sodium alginate powder and dissolve it in 98mL of deionized water under hot bath conditions to prepare a 2% sodium alginate saturated solution , ready to use after cooling;

[0027] S2), add 2 g of urea to the sodium alginate saturated solution, stir magnetically for 30 minutes and then cool to obtain the SAC precursor solution for use;

[0028] S3), ferric nitrate nonahydrate solid powder is dissolved in deionized water, configured into a 5% ferric nitrate solution, and then the SAC precursor solution is added dropwise to the ferric nitrate solution at a rate of 20 drops / min under stirring conditions, When the SAC precursor solution encounters the ferric nitrate solution, small droplets in the shape of wa...

Embodiment 2

[0033] A preparation method of magnetic iron alginate mesoporous carbon microspheres capable of adsorbing heavy metal elements, comprising the following steps:

[0034] S1), using a ten-thousand-digit balance, weigh 3g of sodium alginate powder of chemical purity (viscosity (10g / L) ≥ 0.02Pa·s) and dissolve it in 97mL of deionized water under hot bath conditions to form 3% saturated sodium alginate Solution, stand-by after cooling;

[0035] S2), add 3 g of urea to the sodium alginate saturated solution, stir magnetically for 30 minutes and then cool to obtain the SAC precursor solution for use;

[0036] S3), ferric nitrate nonahydrate solid powder is dissolved in deionized water, configured into a 5% ferric nitrate solution, and then the SAC precursor solution is added dropwise to the ferric nitrate solution at a rate of 20 drops / min under stirring conditions, When the SAC precursor solution encounters the ferric nitrate solution, small droplets in the shape of water will be f...

Embodiment 3

[0041] A preparation method of magnetic iron alginate mesoporous carbon microspheres capable of adsorbing heavy metal elements, comprising the following steps:

[0042] S1), using a ten-thousand-digit balance, weigh 3g of sodium alginate powder of chemical purity (viscosity (10g / L) ≥ 0.02Pa·s) and dissolve it in 97mL of deionized water under hot bath conditions to form 3% saturated sodium alginate Solution, stand-by after cooling;

[0043] S2), adding 3 g of urea in parts by mass to the saturated sodium alginate solution, stirring with magnetic force for 30 minutes, cooling to obtain the SAC precursor solution for use;

[0044] S3), ferric nitrate nonahydrate solid powder is dissolved in deionized water, configured into a 10% ferric nitrate solution, and then the SAC precursor solution is added dropwise to the ferric nitrate solution at a rate of 20 drops / min under stirring conditions, When the SAC precursor solution encounters the ferric nitrate solution, small droplets in t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com