Energy-saving process method for recovering butane in mixed C4

A process method and butane technology, which is applied in the field of energy-saving process for recovering butane in mixed C4, can solve the problems of high theoretical plate number, high equipment cost, high energy consumption, etc., achieve simple distillation range, reduce energy consumption, Effect of Condensed Water Consumption Reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

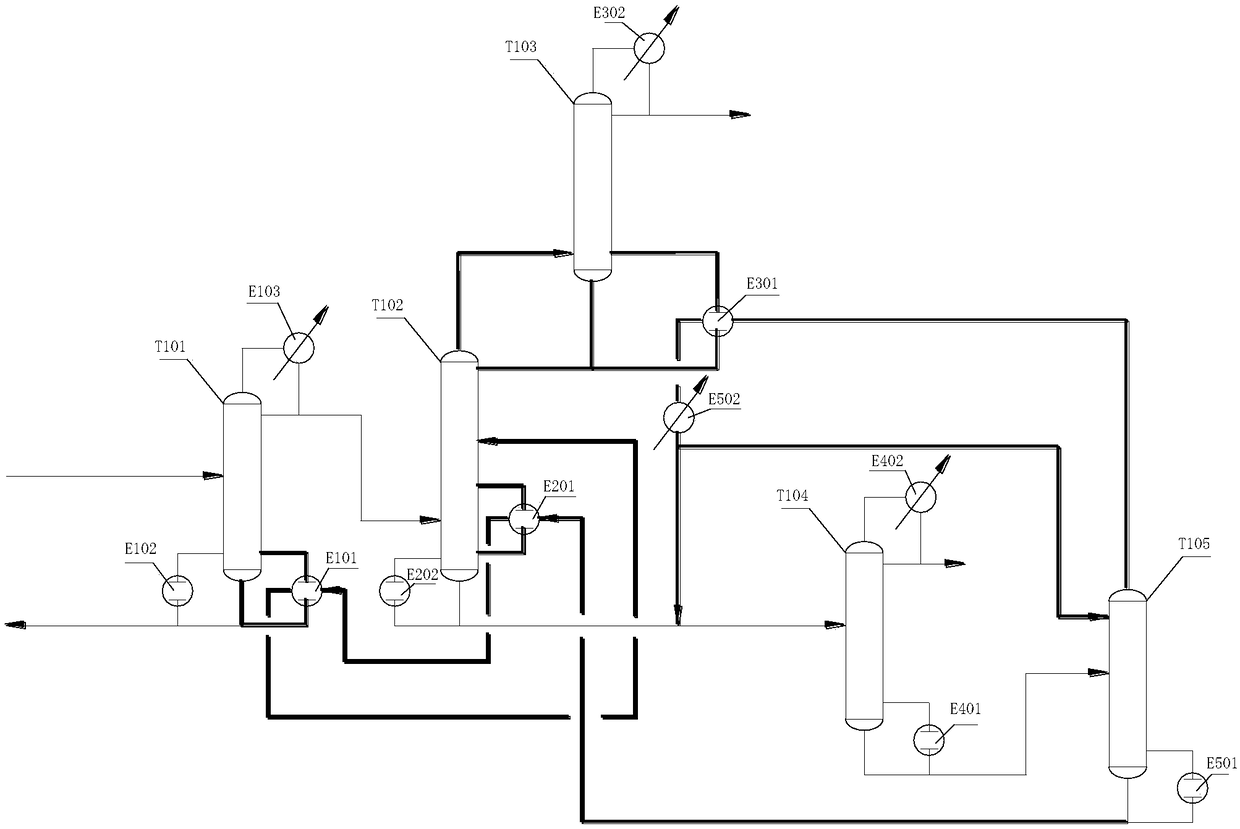

[0026] Attached below figure 1 The present invention will be further described with reference to specific embodiments.

[0027] Raw material composition:

[0028] Isobutane

n-butane

Anti-butene

n-pentane

1,3-Butadiene

0.4800

0.1600

0.1300

0.1230

0.0060

0.0020

0.0980

0.0010

[0029] An energy-saving process for recovering butane in mixed C4, including rectification consisting of alkene crude fractionation tower, extractive distillation tower, upper extractive distillation tower, extraction agent recovery I tower, extractant recovery II tower and heat exchanger The device is characterized in that the gas phase at the top of the alkene crude separation tower T101 is condensed and cooled by the top condenser E103 and then enters the lower part of the extractive distillation tower T102, part of the material in the tower tank is heated and vaporized by the reboiler E102 and then returned ...

Embodiment 2

[0036] Raw material composition:

[0037] Isobutane

n-butane

Anti-butene

n-pentane

Butene

1,3-Butadiene

0.4800

0.1600

0.1300

0.1230

0.0060

0.0020

0.0980

0.0010

[0038] The energy-saving process of recovering and mixing butane in C4 in this embodiment is the same as that in Embodiment 1.

[0039] The operating pressure of each column is as follows:

[0040] The operating pressure of extractive distillation tower T101 is 0.5MPa, the operating pressure of extractive distillation tower T102 is 0.5MPa, the operating pressure of extractive distillation upper tower T103 is 0.5MPa, the operating pressure of extraction agent recovery I tower T104 is 0.5MPa, and the operation pressure of extractant recovery II tower T105 Pressure 0.1MPa.

[0041] The purified isobutane has a purity of 99.8% and a yield of 95%.

[0042] Energy saving and water saving effect (feed rate 1000kg / h):

[0043] ...

Embodiment 3

[0045] Raw material composition:

[0046] Isobutane

n-butane

Butene

Anti-butene

n-pentane

Butene

1,3-Butadiene

0.4800

0.1600

0.1300

0.1230

0.0060

0.0020

0.0980

0.0010

[0047] The energy-saving process of recovering and mixing butane in C4 in this embodiment is the same as that in Embodiment 1.

[0048] The operating pressure of each column is as follows:

[0049] The operating pressure of extractive distillation column T101 is 1.2MPa, the operating pressure of extractive distillation column T102 is 1.2MPa, the operating pressure of extractive distillation upper column T103 is 1.2MPa, the operating pressure of extraction agent recovery I column T104 is 1.2MPa, and the operation pressure of extractant recovery II column T105 Pressure 0.6MPa.

[0050] The purified isobutane has a purity of 99.8% and a yield of 95%.

[0051] Energy saving and water saving effect (feed rate 1000kg / h):

[0052] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com