Lotus-leaf-like self-cleaning finishing varnish and preparation method thereof

A kind of finishing varnish and lotus leaf technology, which is applied in the direction of biocide-containing paint, coating, antifouling/underwater coating, etc., can solve the problem that pollutants or liquids cannot be completely attached, and achieve improved self-cleaning performance, Good construction and transparent appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment A

[0047] Example A: Preparation of SiO 2 / TiO 2 Nanocomposite

[0048] Propylene B wood fiber, tetraethoxysilane, tetrabutyl titanate, ethanol and hydrochloric acid (36-38%) are used as raw materials, among which, tetrabutyl titanate: tetraethoxysilane: EtOH: propane B wood fiber : Molar ratio of HCl=1:1.5:25:10:0.002,

[0049] Add absolute ethanol and propane B wood fiber to the reactor first; then add tetrabutyl titanate to form a solution, add a quantitative hydrochloric acid solution dropwise, stir for 2 hours, put it into a constant temperature drying box, and prepare a xerogel for use.

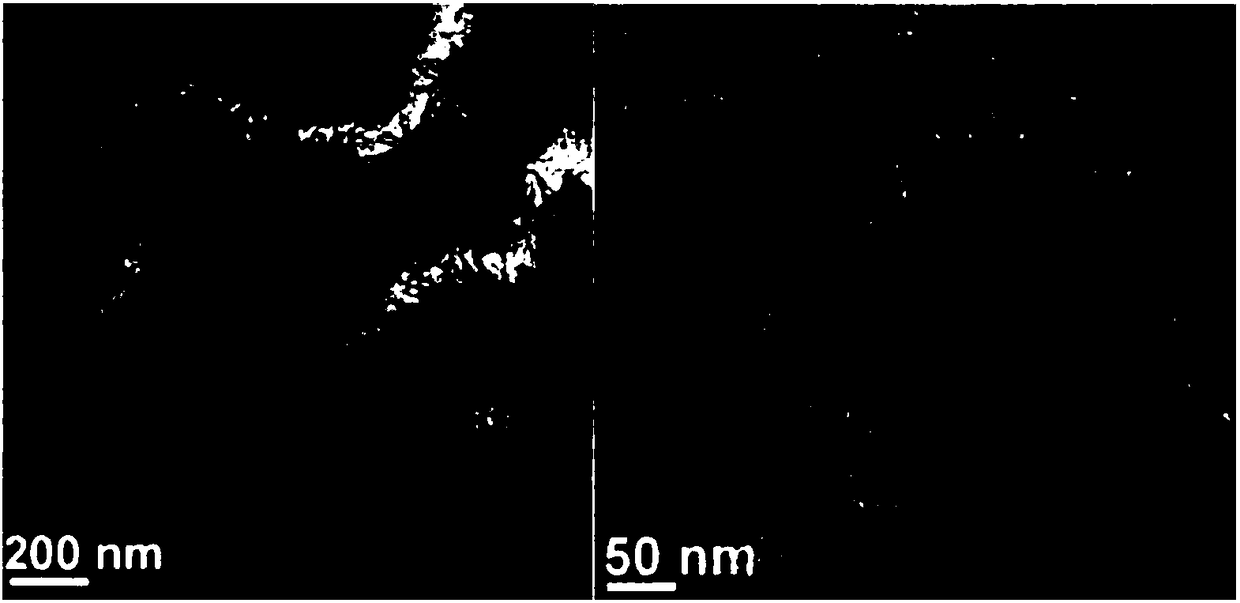

[0050] Put the dry gel into the muffle furnace, raise the temperature to 400 and 450°C at a heating rate of 1°C / min, remove the solvent, and grow the crystal to finally produce SiO 2 / TiO 2 Composite material, its TEM electron microscope picture is as follows figure 1 As shown, its size distribution is uniform, in the range of tens of nanometers, it can be seen that the final product ...

Embodiment B

[0051] Example B: Preparation of Rough Titanium Dioxide Micro-Nanomaterials

[0052] Using titanium tetrachloride, absolute ethanol and hydrochloric acid (36-38%) as raw materials, TiCl 4 : EtOH: HCl molar ratio = 1:25:0.002,

[0053] First add absolute ethanol into the reactor; then add titanium tetrachloride to form a yellow solution, dropwise add quantitative hydrochloric acid solution, and stir for 2 hours; finally, put it into a constant temperature drying box to prepare a xerogel for use.

Embodiment 1

[0056] First add 200g of deionized water to the mixer, then add 3g of defoamer (MDF), 3g of wetting agent (CF-10), 600 rpm, and continue stirring for 10 minutes;

[0057] Then add aqueous emulsion 350g, SiO 2 / TiO 2 Nanocomposite material 40g, rough titanium dioxide micro-nano material 40g, bactericide (DB20 of Sol) 8g, antifungal agent (HF of Sol) 5g, film-forming aid diethylene glycol butyl ether 30g, 800 rpm Minutes, continuous stirring for 30 minutes;

[0058] Finally, add 15g of thickener (RHEOLATE 150 from Elementis), stir for 30-50 minutes, until the viscosity is stable, filter and fill.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com