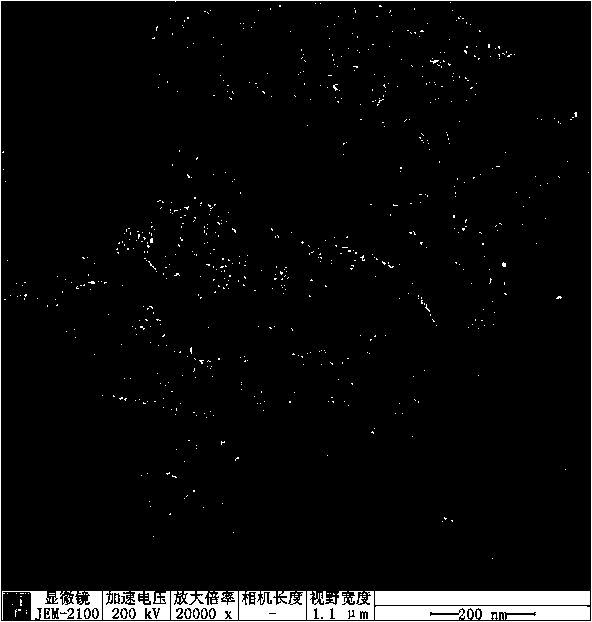

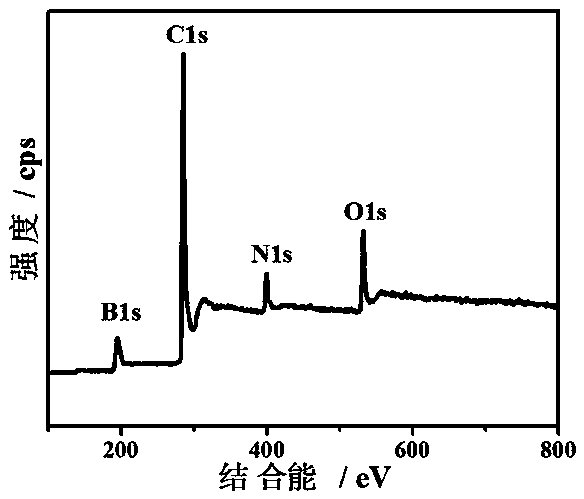

Method for preparing carbon nanotube/boron nitrogen co-doped porous carbon composite material

A technology of carbon nanotubes and composite materials, applied in the direction of hybrid capacitor electrodes, etc., can solve the problems of poor safety, low yield, complex synthesis methods, etc., and achieve the effect of improving electrical conductivity and high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The preparation method of the carbon nanotube / boron-nitrogen co-doped porous carbon composite material of this embodiment comprises the following steps:

[0042] (1) Disperse 0.2 g of carbon nanotubes in 50 mL of deionized water to obtain a suspension of carbon nanotubes, and add 1 g of polyvinylpyrrolidone to the suspension. After stirring for 4 hours at a stirring speed of 1000 rpm, the solid phase was obtained by filtration, washed and then dried at 60°C to obtain pretreated carbon nanotubes;

[0043] (2) Ultrasonic disperse 0.2g of pretreated carbon nanotubes into 50mL of aqueous solution, add a certain amount of melamine and sodium hydroxide activator to the solution, and stir at a temperature of 50°C and a stirring speed of 100r / min. 2h, wherein the mass ratio of pretreated carbon nanotubes to nitrogen-containing carbon source and activator is 1:4:8.

[0044] (3) Add 0.8 g of boric acid to the solution obtained in step 2, continue to stir for 4 h at a temperature...

Embodiment 2

[0054] (1) Disperse 0.2 g of carbon nanotubes in 100 mL of deionized water to obtain a suspension of carbon nanotubes, and add 1.8 g of polyvinylpyrrolidone to the suspension. After stirring for 7 hours at a stirring speed of 500 rpm, the solid phase was obtained by filtration, washed and then dried at 80°C to obtain pretreated carbon nanotubes;

[0055] (2) Ultrasonic disperse 0.2g of pretreated carbon nanotubes into 60mL of aqueous solution, add a certain amount of melamine and sodium hydroxide activator to the solution, and stir at a temperature of 30°C and a stirring speed of 200r / min. 5h, wherein the mass ratio of pretreated carbon nanotubes to nitrogen-containing carbon source and activator is 1:5:12.

[0056] (3) Add 1.0 g of boric acid to the suspension obtained in step 2, continue to stir for 7 hours at a temperature of 80°C and a stirring speed of 200r / min, and then solidify at a temperature of 120°C to obtain a solid ligand.

[0057] (4) The solid ligand obtained i...

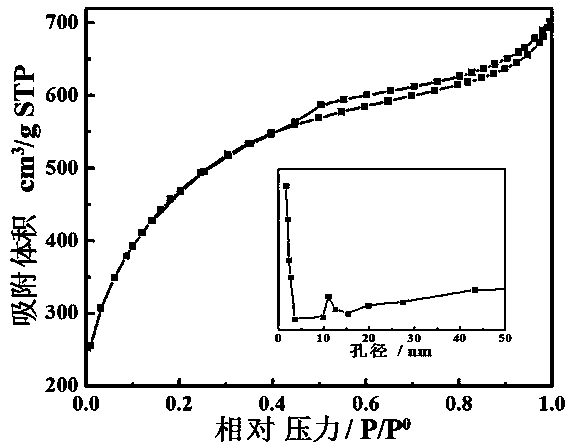

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com