Sulfur-loaded MOF@ conductive polymer material and preparation method and application thereof

A conductive polymer and sulfur-carrying technology, applied in circuits, electrical components, battery electrodes, etc., can solve the problems of low conductivity, low discharge specific capacity, low sulfur utilization rate, etc., achieve high specific capacity, and simple preparation process , Discharge specific capacity and improved cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

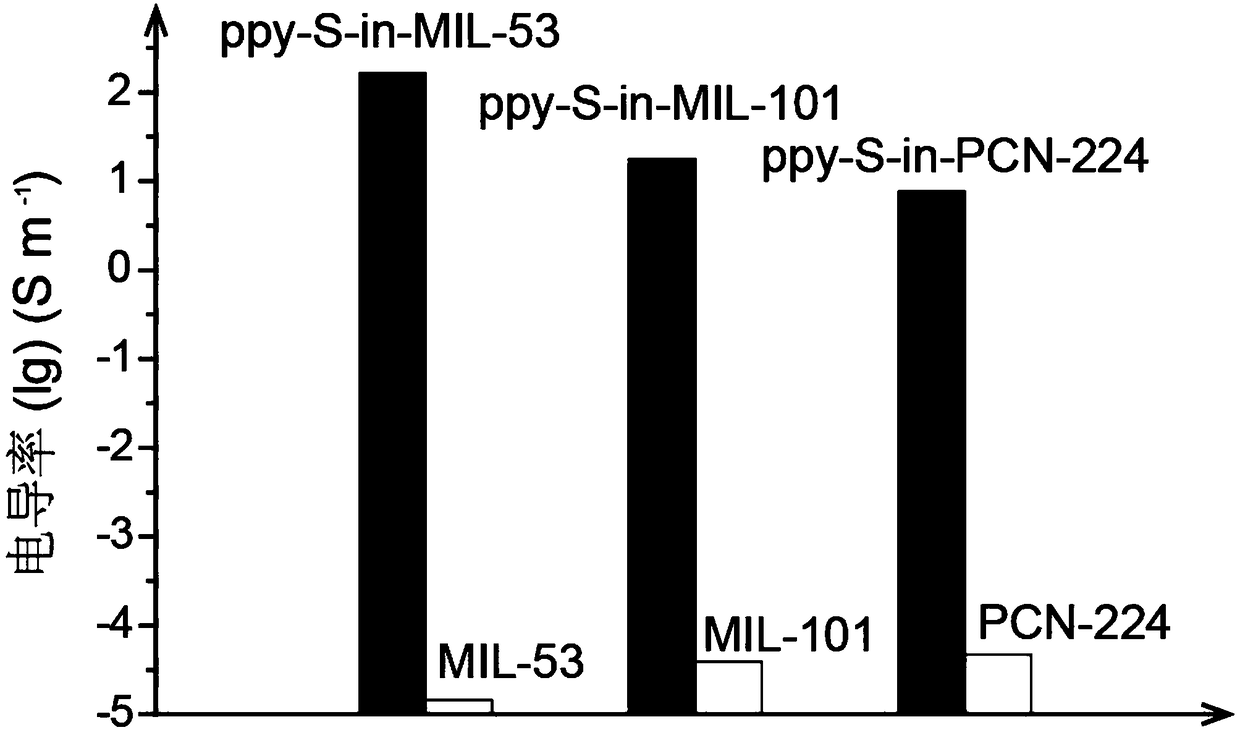

Embodiment 1

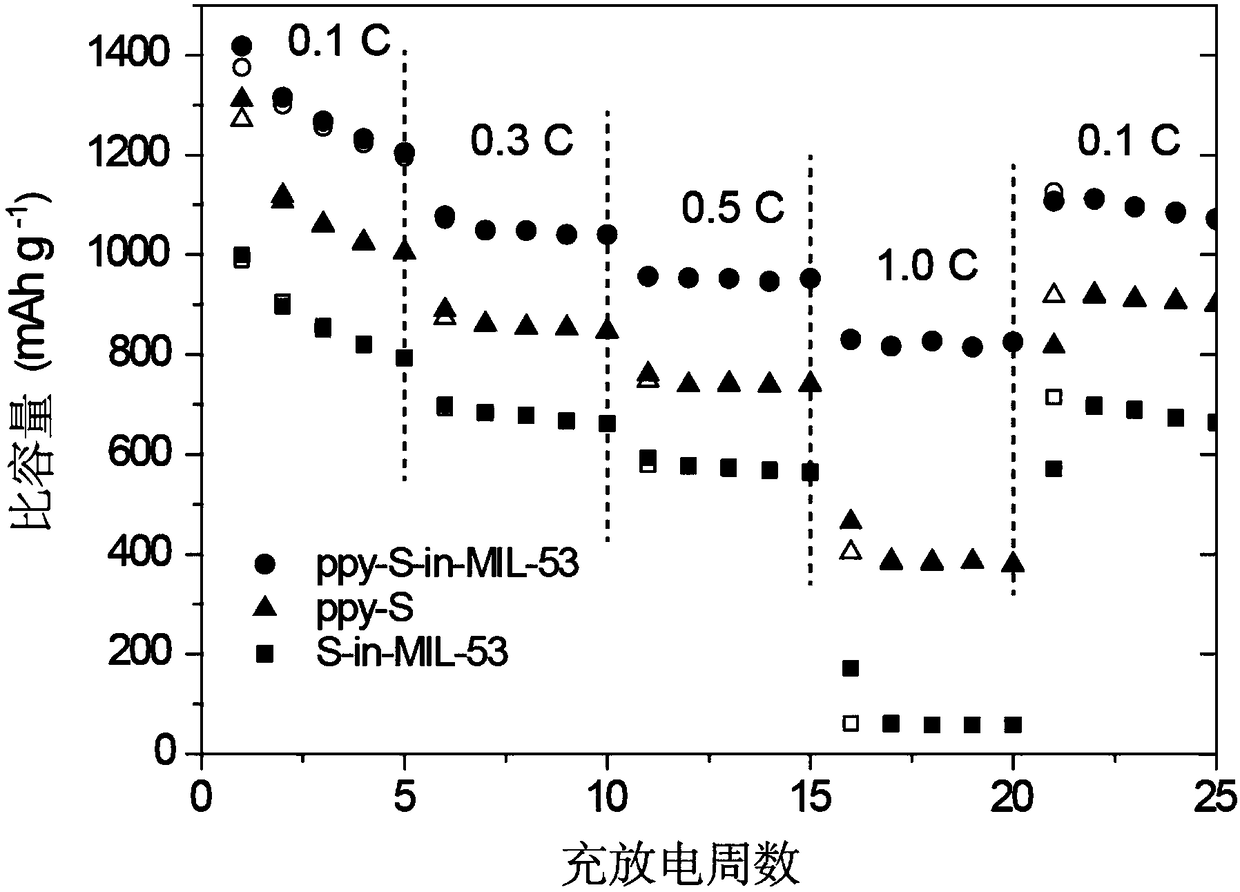

[0035] Step 1): Weigh 120 mg of degassed MIL-53 powder and 180 mg of sublimed sulfur, mix them and grind them evenly in a mortar, seal the mixture in a glass tube after grinding, and then place the glass tube in a convection current at 155°C Heated in an oven for 12 hours, took out the glass tube, and naturally cooled to room temperature to obtain the sulfur-loaded MOF material S-in-MIL-53.

[0036] Step 2): Prepare 0.4M polyvinylpyrrolidone aqueous solution (PVP, K30, 0.02g / mL) to modify S-in-MIL-53. Weigh 70 mg of S-in-MIL-53, pour it into 10 mL of 0.4 M polyvinylpyrrolidone aqueous solution, stir at room temperature for 10 minutes, then centrifuge repeatedly three times, then wash with deionized water, and collect the precipitate. Finally, the precipitate was ultrasonically dispersed in 10 mL of deionized water, then poured into a 50 mL round bottom flask, and stirred evenly by magnetic force to obtain the modified S-in-MIL-53 aqueous dispersion.

[0037] Step 3): Preparat...

Embodiment 2

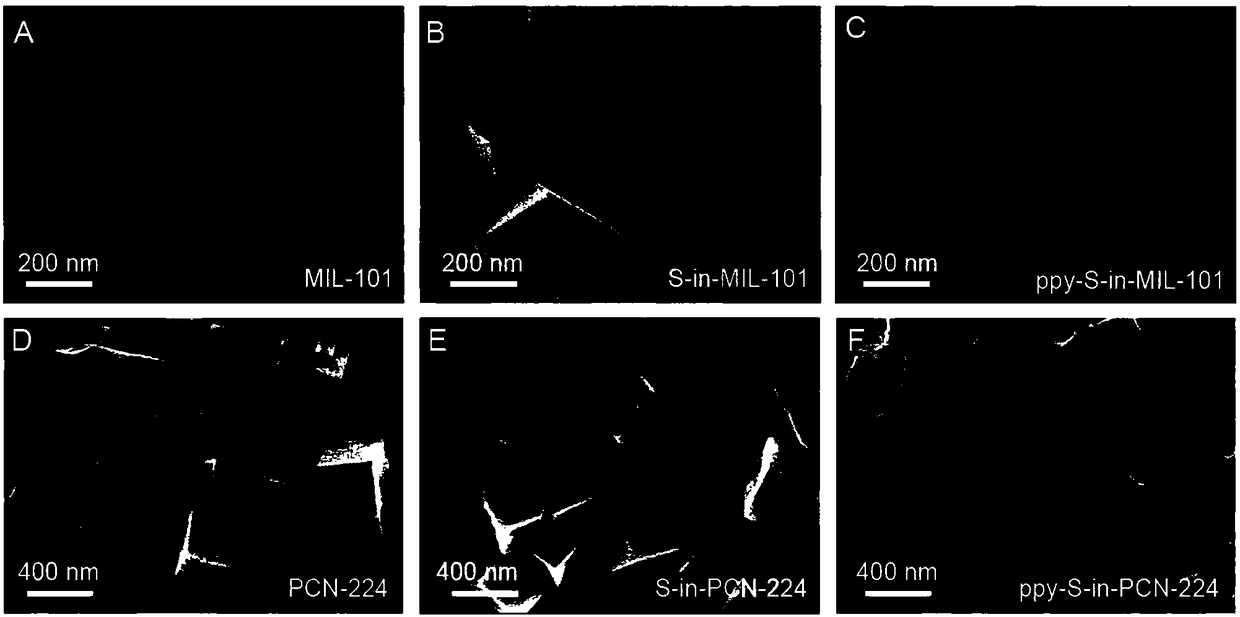

[0042] Step 1): Weigh 80 mg of degassed MIL-101 powder and 120 mg of sublimed sulfur, mix them and grind them evenly in a mortar, seal the mixture in a glass tube after grinding, and then place the glass tube in a convection type Heated in the oven for 12 hours, took out the glass tube, and naturally cooled to room temperature to obtain the sulfur-loaded MOF material S-in-MIL-101.

[0043] Step 2): Dissolve 1.2mg of sodium dodecylbenzenesulfonate (SDBS) in 10mL of water and pour it into a 50mL flask, then add 100mg of S-in-MIL-101, ultrasonically disperse and add 40μL of aniline mono body, stirred for 10 minutes, then added 120 μL of concentrated hydrochloric acid and continued to stir for 10 minutes.

[0044] Step 3) Dissolve 100 mg of sodium persulfate in 5 mL of deionized water and pour it into the above-mentioned flask as a polymerization agent, and continue to stir for 12 hours at room temperature.

[0045] Step 4): Centrifuge the solution after polymerization and collec...

Embodiment 3

[0049] Step 1): Weigh 80 mg of degassed PCN-224 powder and 120 mg of sublimed sulfur, mix them and grind them evenly in a mortar, seal the mixture in a glass tube after grinding, and then place the glass tube in a convection type The oven was heated for 12 hours, the glass tube was taken out, and cooled to room temperature naturally to obtain the sulfur-loaded MOF material S-in-PCN-224.

[0050] Step 2): Prepare 0.4M polyvinylpyrrolidone aqueous solution (PVP, K30, 0.02g / mL) to modify S-in-PCN-224. Add 70mg of S-in-PCN-224 into 10mL of 0.4M polyvinylpyrrolidone aqueous solution, stir at room temperature for 10 minutes, centrifuge repeatedly three times, wash with deionized water, collect the precipitate, ultrasonically disperse the precipitate in 10mL of deionized water, and then Pour it into a 50mL round-bottomed flask and stir evenly with magnetic force to obtain the modified S-in-PCN-224 water dispersion.

[0051] Step 3): Preparation of Fe-containing 3+ Aqueous solution ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com