Metal etching solution applied to copper-molybdenum film layer

A technology of metal etching and film layer, which is applied in the field of etching solution, can solve the problems of high harm to users, etching of glass substrates, high corrosiveness of fluorine ions, etc., and achieve the effect of reducing processing costs and widening the operating window

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following are only preferred embodiments of the present invention, and therefore do not limit the protection scope of the present invention.

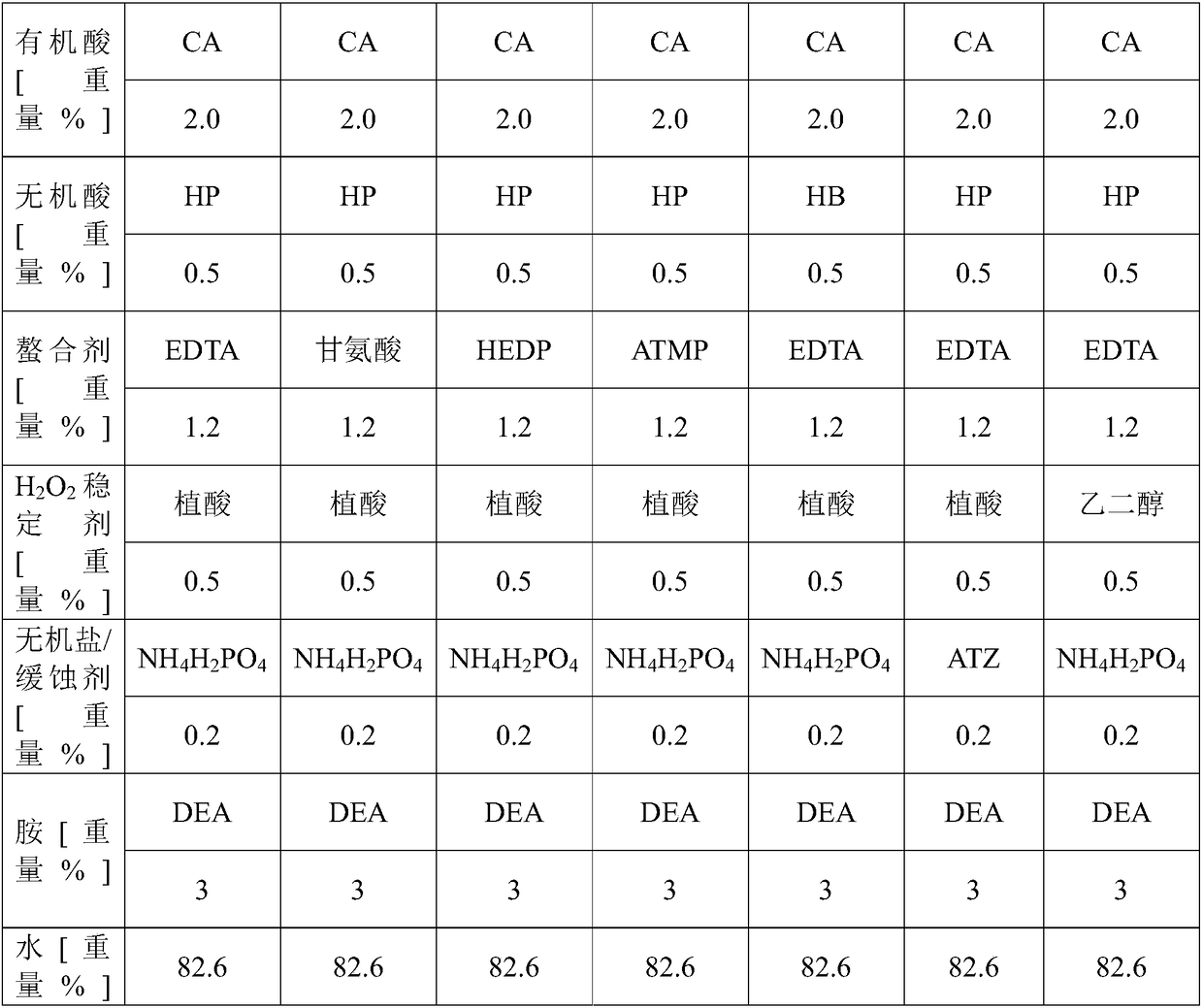

[0019] A metal etching solution applied to a copper-molybdenum film layer, which is composed of the following components according to weight percentage: 5%-10% of oxidizing agent; 1%-5% of organic acid; 1%-5% of inorganic acid; 0.5% of chelating agent -5%; Amine 1% -5%; H 2 o 2 Stabilizer 0.1%-2%; Inorganic salt 0.1%-1%; Water 10%-90%.

[0020] in,

[0021] Oxidant is H 2 o 2 , H 2 o 2 Oxygen ions [OH] are produced by decomposition 2 - ], to ensure that the etching is carried out, and to determine the etching rate;

[0022] The organic acid is one or more of water-soluble organic acids such as citric acid, tartaric acid, malic acid, salicylic acid, glycolic acid, and acetic acid;

[0023] The inorganic acid replaces the fluoride, and the inorganic acid is one or more of phosphoric acid, boric acid, nitric acid, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com