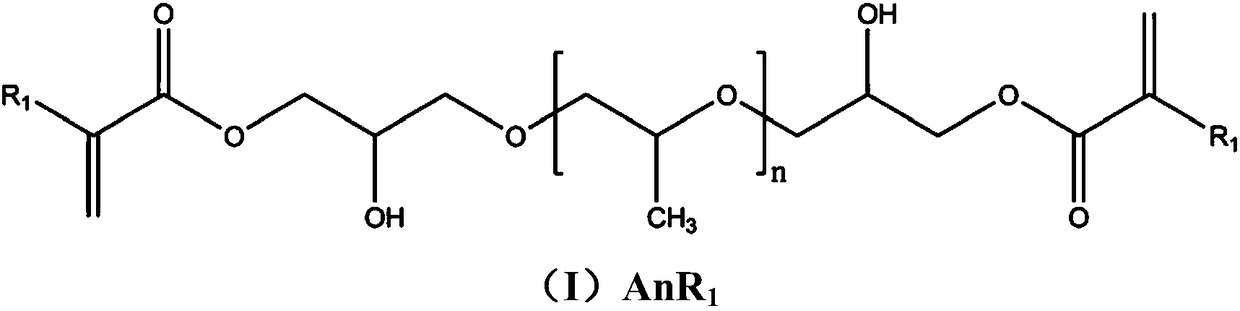

Composite resin with low contraction stress containing dimethacrylate with long oxyalkyl chain for dental department and preparation method of composite resin

A technology of acrylate and composite resin, which is applied in dental preparations, dentistry, and dental prostheses. It can solve the problems of bad smell, limited application, poor mechanical properties, etc., and achieve the reduction of polymerization volume shrinkage and shrinkage stress. Polymerization High reactivity and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

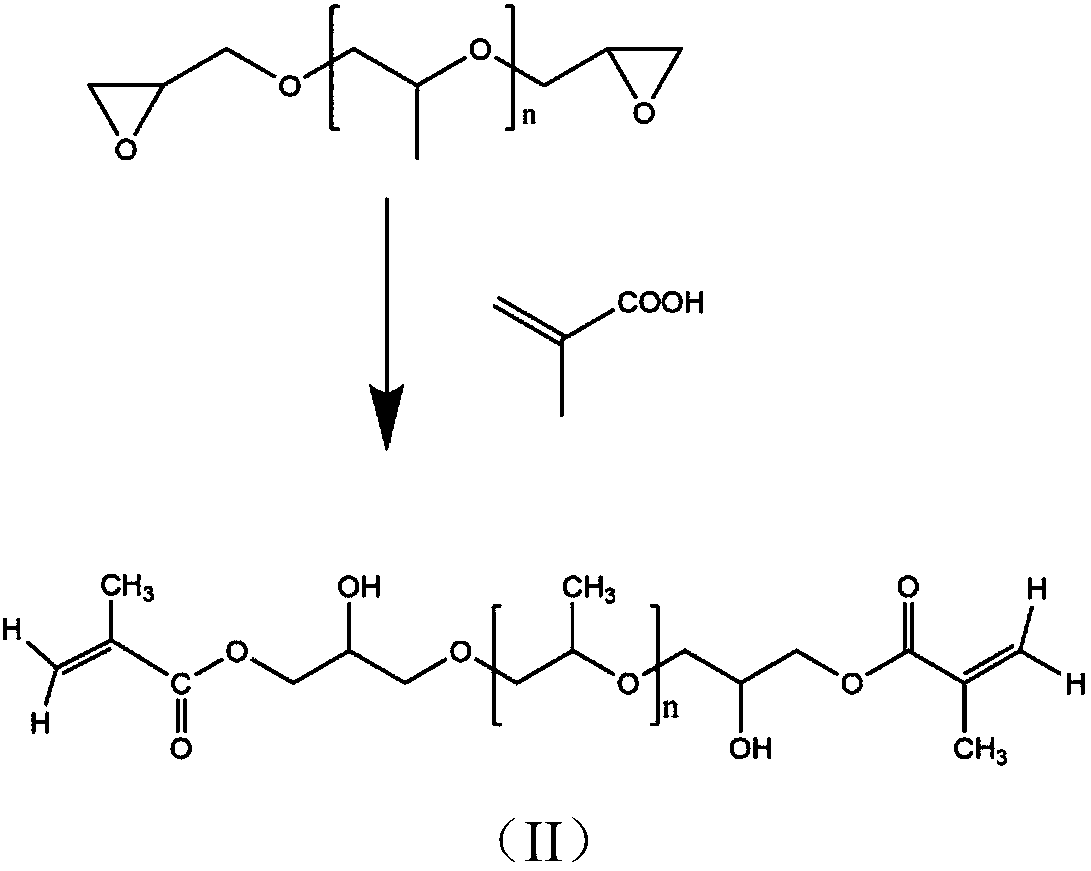

[0032] A4CH 3 Synthesis

[0033] Add 6.92g of polypropylene glycol dioxirane methyl ether (n=4) and 4.50g of methacrylic acid, 0.11g of N,N-dimethylbenzylamine, 0.02g in a round bottom flask equipped with a magnet The hydroquinone was refluxed and stirred at 100°C for 3 hours, cooled to room temperature, and then the reaction product was purified by acid-base washing.

[0034] The product was characterized by infrared and NMR:

[0035] 1 H-NMR (400MHz, CCl 3 D): δ6.07(s), δ5.52(s), δ4.95(s), δ4.14-3.37(m), δ1.88(s), δ1.06(m).

[0036] FT-IR: ν(cm -1 ) 3442, 2973, 2933, 2878, 1724, 1636, 1451, 1380, 1157, 745.

Embodiment 2

[0038] A9CH 3 Synthesis

[0039] Add 13.14g of polypropylene glycol dioxirane methyl ether (n=9) and 6.00g of methacrylic acid, 0.38g of N,N-dimethylbenzylamine, 0.19g in a round bottom flask equipped with a magnet The hydroquinone was refluxed and stirred at 60°C for 24 hours, cooled to room temperature, and then the reaction product was purified by acid-base washing.

[0040] The product was characterized by infrared and NMR:

[0041] 1 H-NMR (400MHz, CCl 3 D): δ6.06(s), δ5.51(s), δ4.94(s), δ4.13-3.41(m), δ1.88(s), δ1.06(m).

[0042] FT-IR: ν(cm -1 ) 3454, 2969, 2928, 2873, 1714, 1633, 1449, 1377, 1171, 745.

Embodiment 3

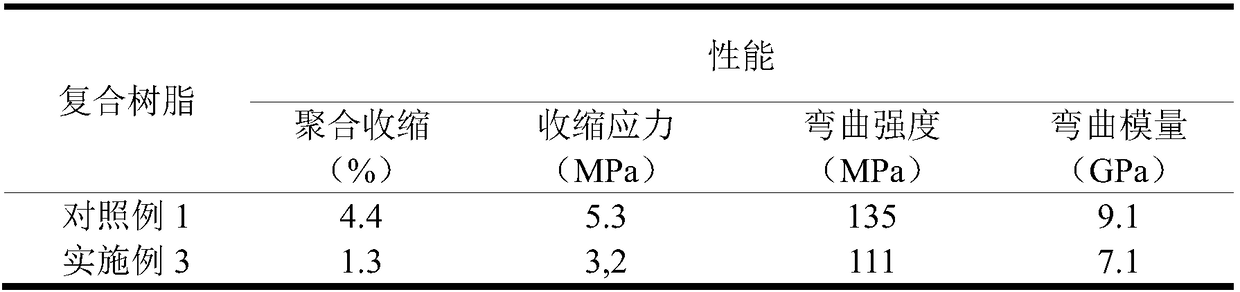

[0045] A low shrinkage stress dental composite resin containing long alkoxy chain bis(meth)acrylate, wherein the mass percentage of each component is: bisphenol A dimethacrylate glycidyl ether ester 12.325%, A4CH 3 6.1625%, triethylene glycol dimethacrylate 6.1625%, camphorquinone 0.175%, dimethylaminoethyl methacrylate 0.175%, silicon dioxide 75%, in the preparation process, bisphenol A dimethacrylate Glycidyl ether ester, A4CH 3and triethylene glycol dimethacrylate are mixed uniformly to prepare a resin matrix, and then the resin matrix is mixed with camphorquinone and dimethylaminoethyl methacrylate to prepare a resin matrix and a photoinitiator mixture, and finally the mixture is mixed with Silica is mixed uniformly to prepare composite resin. This embodiment and comparative example photocured product performance are as follows:

[0046]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com