Method for carrying out flotation of potassium feldspar under condition with neutral pH value

A technology for flotation of potassium feldspar and potassium feldspar, which is applied in flotation, solid separation and other directions, can solve the problem of high impurity content, high potassium feldspar concentrate grade and recovery rate, and unsatisfactory potassium feldspar concentrate grade. problem, to achieve the effect of enhancing hydrophobicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0041] (1) In step A, when the granularity of potassium-containing feldspar material reaches -0.074mm and accounts for 60%, it can directly be made into potassium-containing feldspar slurry; when the granularity of potassium-containing feldspar material is thicker, it is better to The potassium-containing feldspar material is crushed and ground until the particle size is -0.074mm, accounting for 60%, and then made into potassium-containing feldspar slurry. Controlling the particle size of potassium-containing feldspar materials in this range helps to dissociate feldspar and quartz, and the grinding cost is relatively economical.

[0042] (2) In step A, the concentration of the solid phase in the potassium-containing feldspar slurry is preferably 30-45wt%, such as 30wt%, 31wt%, 32wt%, 33wt%, 34wt%, 35wt%, 36wt% %, 37wt%, 38wt%, 39wt%, 40wt%, 41wt%, 42wt%, 43wt%, 44wt%, 45wt% or specific point values between the above-mentioned values, limited by space and for the sake of simp...

Embodiment 1

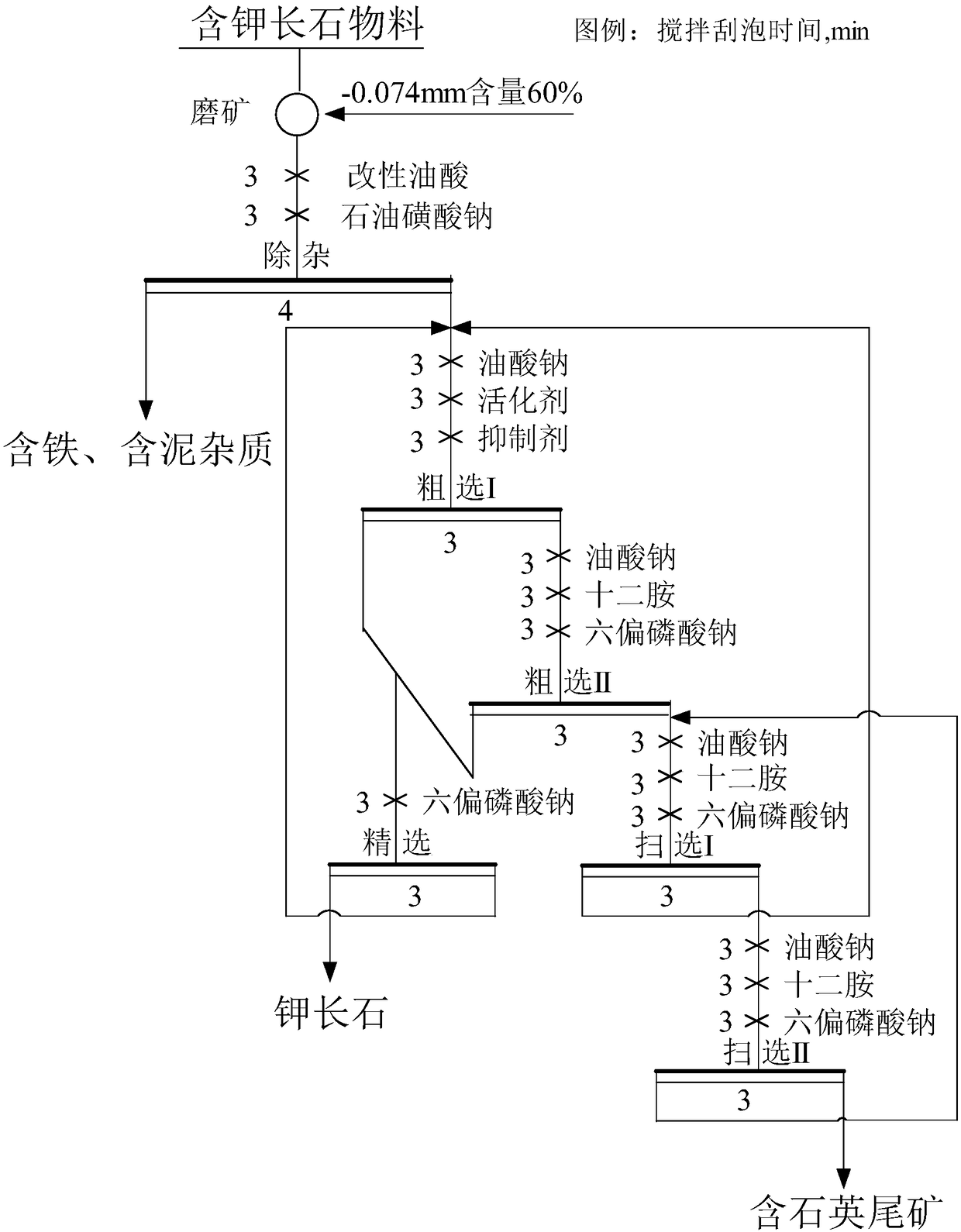

[0061] Such as figure 1 As shown, a neutral pH condition flotation method for potassium feldspar for K 2 O content is 9.65% potassium feldspar raw ore is processed ore dressing, also contains minerals such as quartz, chlorite, magnetite, limonite, hematite in this potassium feldspar raw ore, specific flotation potassium feldspar method can include The following steps:

[0062] Step a1, K 2 The potassium feldspar raw ore with an O content of 9.65% is ground to a particle size of -0.074mm, accounting for 60%, and made into a potassium feldspar slurry with a solid phase concentration of 40wt%.

[0063] Step b1, adding modified oleic acid and sodium petroleum sulfonate to the potassium-containing feldspar pulp described in step a1, the addition of modified oleic acid is 400g / t potassium-containing feldspar material, and the addition of sodium petroleum sulfonate is 500g / t of potassium-containing feldspar material, stirred for 6 minutes, and carried out impurity-removing flotati...

Embodiment 2

[0071] A neutral pH value condition flotation potassium feldspar method for the K 2 O content is 7.25% potassium feldspar raw ore is processed ore dressing, also contains minerals such as quartz, muscovite, limonite, hematite in this potassium feldspar raw ore, concrete flotation potassium feldspar method can comprise the following steps:

[0072] Step a2, K 2 The potassium feldspar raw ore with an O content of 7.25% was ground to a particle size of -0.074mm, accounting for 60%, and made into a potassium feldspar slurry with a solid phase concentration of 38wt%.

[0073] Step b2, adding modified oleic acid and sodium petroleum sulfonate to the potassium-containing feldspar pulp described in step a2, the addition of modified oleic acid is 300g / t potassium-containing feldspar material, and the addition of sodium petroleum sulfonate is 400g / t of potassium-containing feldspar material, stirred for 6 minutes, and subjected to impurity-removing flotation to remove iron-containing a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com