Sewage treatment biological membrane carrier device based on soybean straw and application method of device

A technology of biofilm carrier and soybean straw, which is applied in biological water/sewage treatment, water/sludge/sewage treatment, backflow water treatment, etc., and can solve problems such as poor mass transfer capacity, excess straw, and weak corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

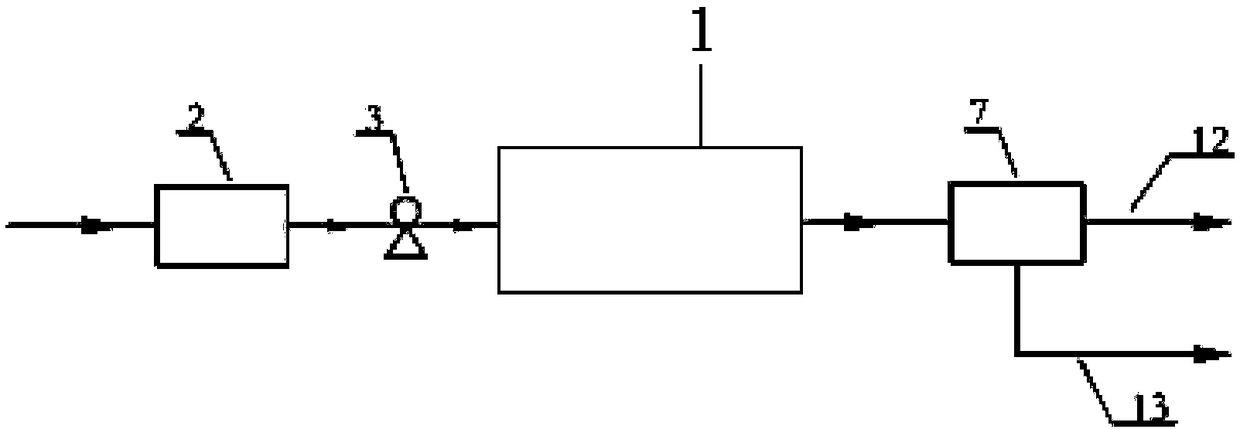

[0058] Specific implementation mode 1: This implementation mode is a device for sewage treatment biofilm carrier based on soybean stalks, such as Figure 1-Figure 10 , specifically composed of a regulating tank 2, an inlet pump 3, a biochemical system 1 and a secondary sedimentation tank 7;

[0059] The water outlet of the regulating tank 2 is connected to the water inlet of the water inlet pump 3, the water outlet of the water inlet pump 3 is connected to the water inlet of the biochemical system 1, and the water outlet of the biochemical system 1 is connected to the water inlet of the secondary sedimentation tank 7;

[0060] The biochemical system 1 is a double-tank switching biofilm system or a single-tank switching biofilm system;

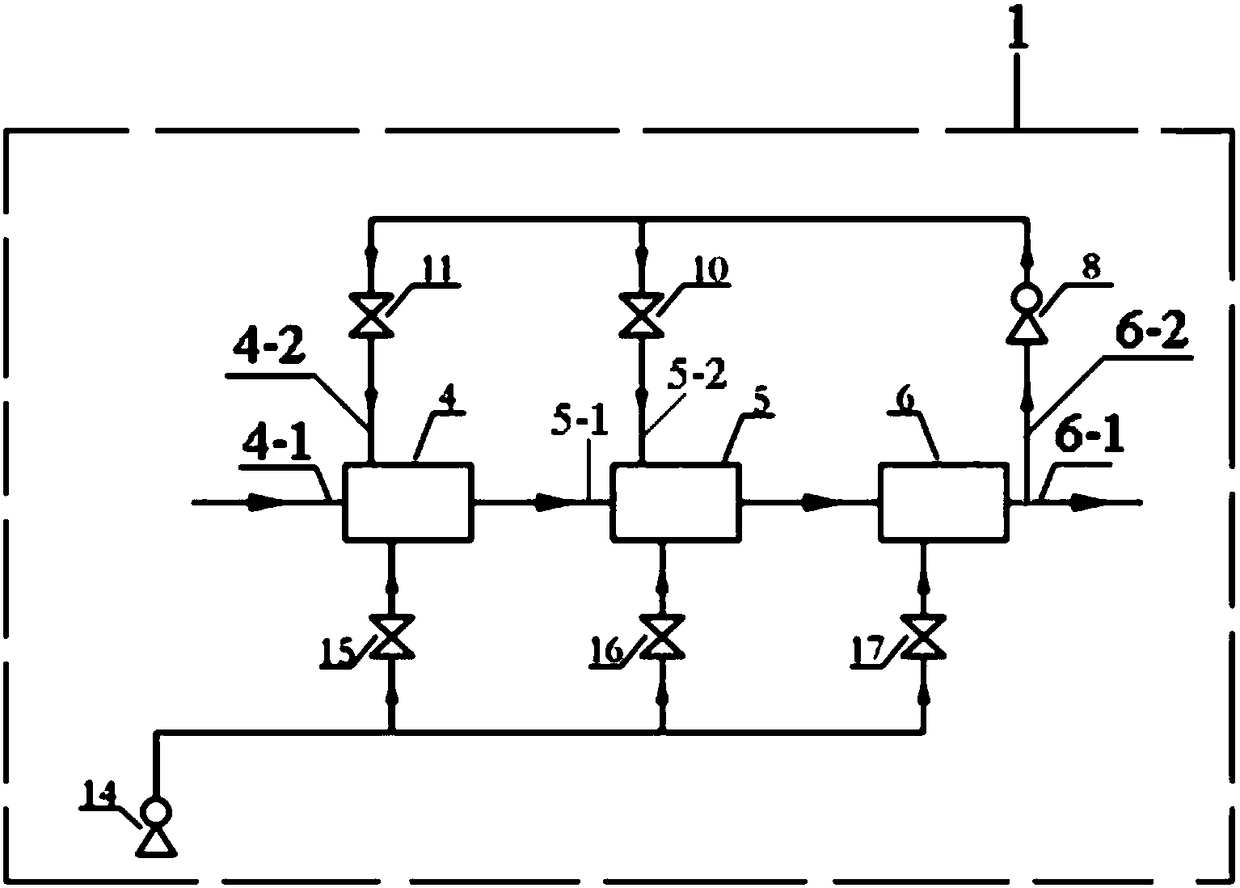

[0061] The two-tank switching biofilm system consists of the first biochemical tank 4, the second biochemical tank 5, the third biochemical tank 6, the first backflow pump 8, the second valve 10, the first valve 11, the first aeration fan 14. ...

specific Embodiment approach 2

[0078] Embodiment 2: This embodiment is the method of using the biofilm carrier device for sewage treatment based on soybean stalks in Embodiment 1. When the biochemical system 1 is a dual-tank switching biofilm system, the specific steps are as follows:

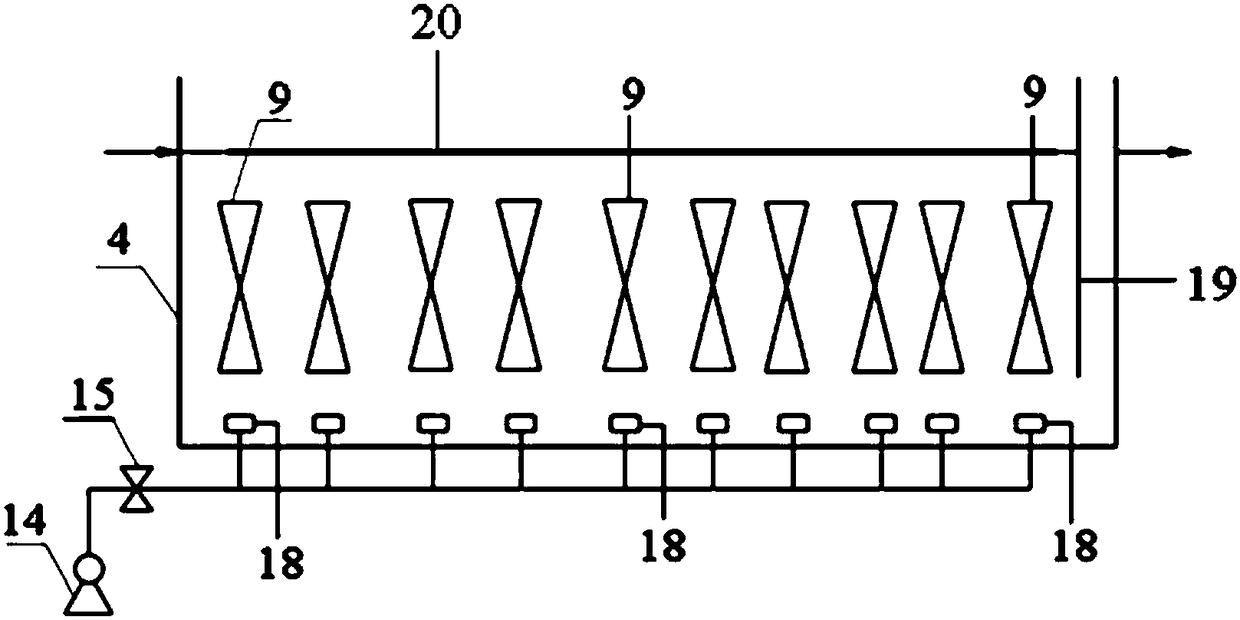

[0079] One, carrier film: inject tap water or clear water in the first biochemical pool 4, the second biochemical pool 5 and the third biochemical pool 6, so that the upper edge of the first biofilm carrier 9 in the three pools is higher than the water surface in the pool 20 0~80cm, soak for 24h~72h, start the first aeration fan 14 to start aeration, the volume ratio of the aeration volume per hour to the water in the biochemical pool is (15~20):1, to the three pools The secondary sedimentation tank sludge transported from abroad is added for inoculation. The inoculum amount of the secondary sedimentation tank sludge imported from abroad is 10% to 15% of the effective pool volume of a single biochemical tank, reducing the amo...

specific Embodiment approach 3

[0085] Embodiment 3: This embodiment is the method of using the biofilm carrier device for sewage treatment based on soybean stalks in Embodiment 1. When the biochemical system 1 is a single-tank switching biofilm system, the specific steps are as follows:

[0086] 1. Carrier membrane: Inject tap water or clean water into the pool body 21 so that the upper edge of the second biofilm carrier 26 in the pool is 0-80 cm lower than the water surface 23 in the pool, soak for 24h-72h, and start the second aeration Fan 29 starts aeration, opens all the 4th gas flow regulating valves 24, and the volume ratio of the aeration volume per hour and the water in the biochemical pond is (15~20):1, adds the external transported in the pond Inoculate the sludge from the secondary settling tank. The inoculum amount of the sludge from the secondary settling tank imported from abroad is 10% to 15% of the effective tank volume of the biochemical tank. Reduce the amount of aeration and control the di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com