A kind of anti-freezing and thawing water-based epoxy mortar and preparation method thereof

A water-based epoxy, anti-freeze-thaw technology, applied in the field of construction repairs, can solve the problems of epoxy mortar such as long solidification time, poor anti-freeze performance, short gel time, etc., and achieve good workability and good anti-vibration performance , fast curing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

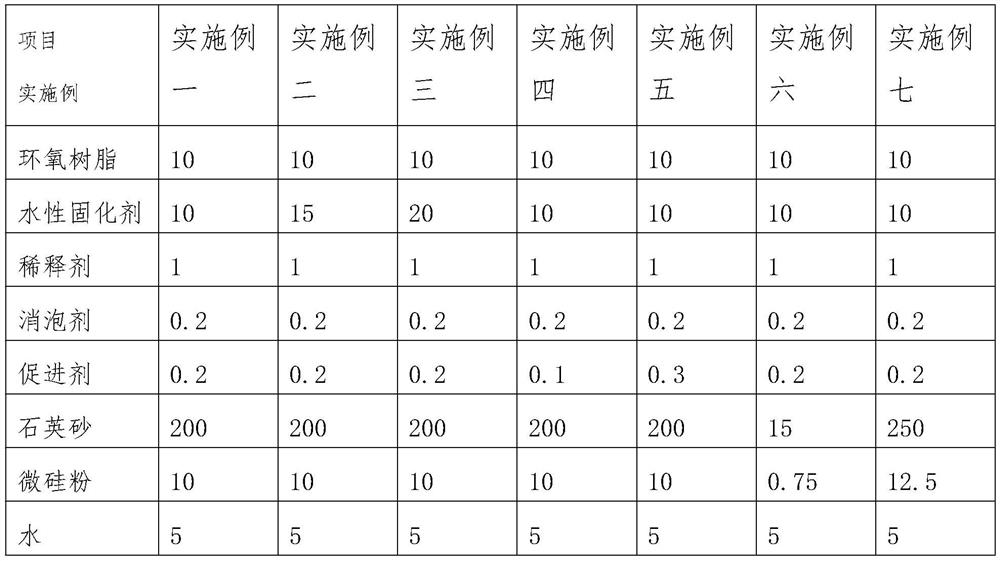

Embodiment 1

[0034] Step 1: Mix 10kg of bisphenol A epoxy resin E-51 with 1kg of reactive diluent butyl glycidyl ether, and leave to stand for defoaming to obtain component A; mix 10kg of triethylenetetramine epoxy adduct, 5kg Tap water, 0.2kg of defoamer and 0.2kg of DMP-30 accelerator are mixed evenly, and left to defoam to obtain component B; 10kg of 20-40 mesh round quartz sand, 5kg of 40-70 mesh round quartz sand, Mix 5kg of 140-mesh round quartz sand and 1kg of micro-silica fume evenly to obtain component C.

[0035] Step 2: Mix 1kg of component A with 1.5kg of component B, stir until pure milky white, then add 25kg of component C to obtain high-strength repair mortar.

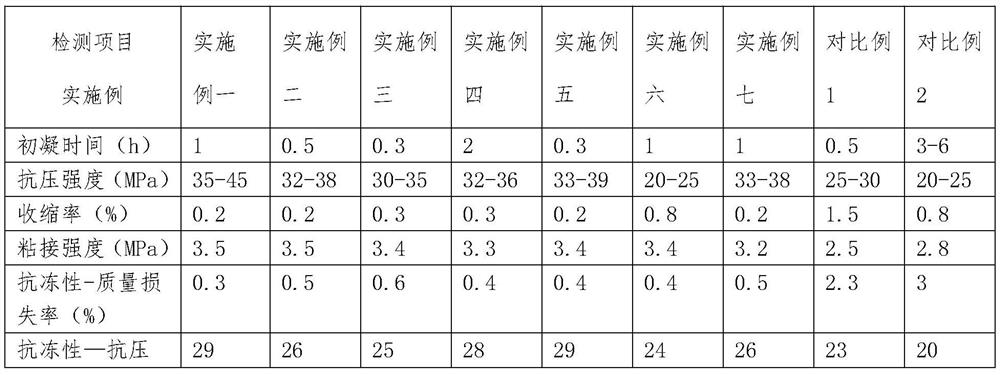

[0036] According to test results, its compressive strength is 35MPa, water absorption is less than 0.2%, the mass loss rate after 7 days of 5% hydrochloric acid solution treatment is 2.5%, compressive strength is 28MPa, freeze-thaw test (one cycle: -80 ℃ process 12h , 120°C treatment for 12h) after five cycles, its ...

Embodiment 2

[0038] The preparation method of the freeze-thaw resistant water-based epoxy mortar in Example 2 is exactly the same as that in Example 1, except that the triethylenetetramine epoxy adduct in Example 2 is 15 parts, and the proportions of other components are exactly the same.

Embodiment 3

[0040] The preparation method of the freeze-thaw resistant water-based epoxy mortar in Example 3 is exactly the same as that in Example 1, except that the triethylenetetramine epoxy adduct in Example 3 is 20 parts, and the proportions of other components are exactly the same.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com