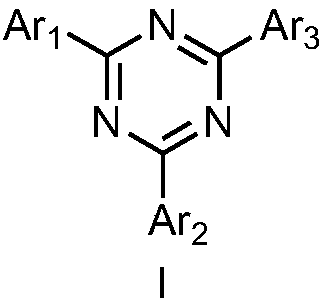

Triazine compound containing fluorene structure and organic luminous device thereof

A technology of organic light-emitting devices and triazine compounds, applied in the field of organic optoelectronic materials, can solve problems such as device performance degradation, and achieve the effects of low driving voltage, stable structure, and prevention of aggregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

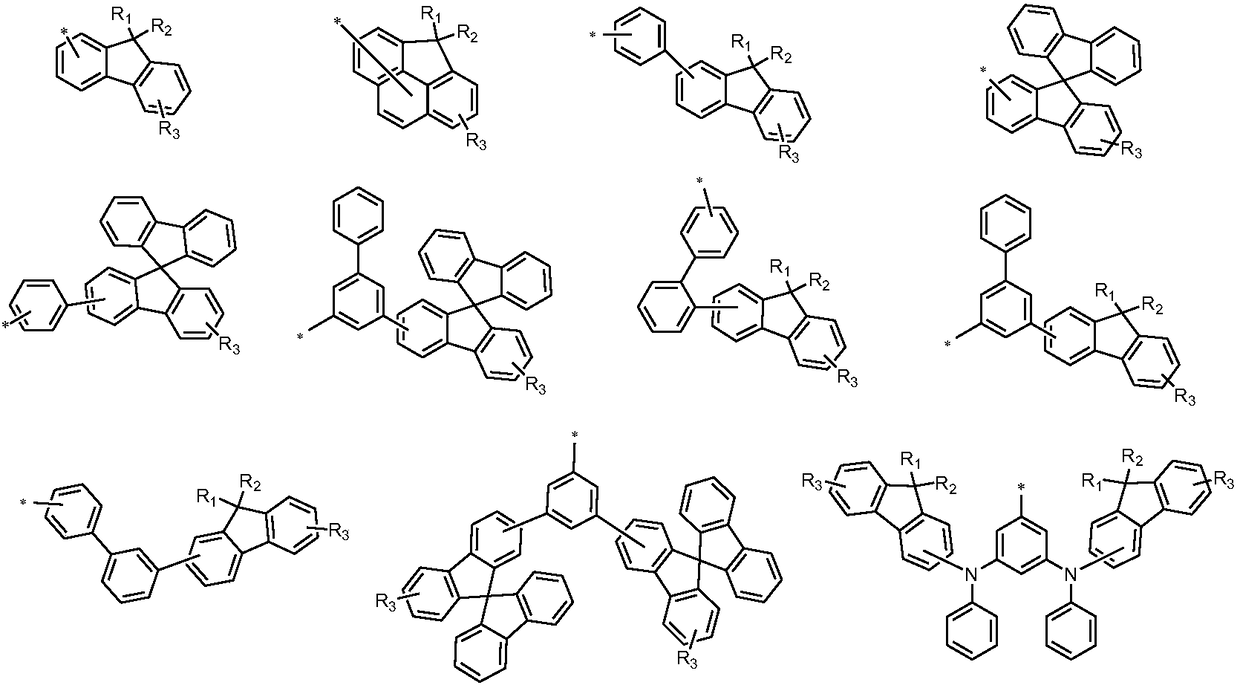

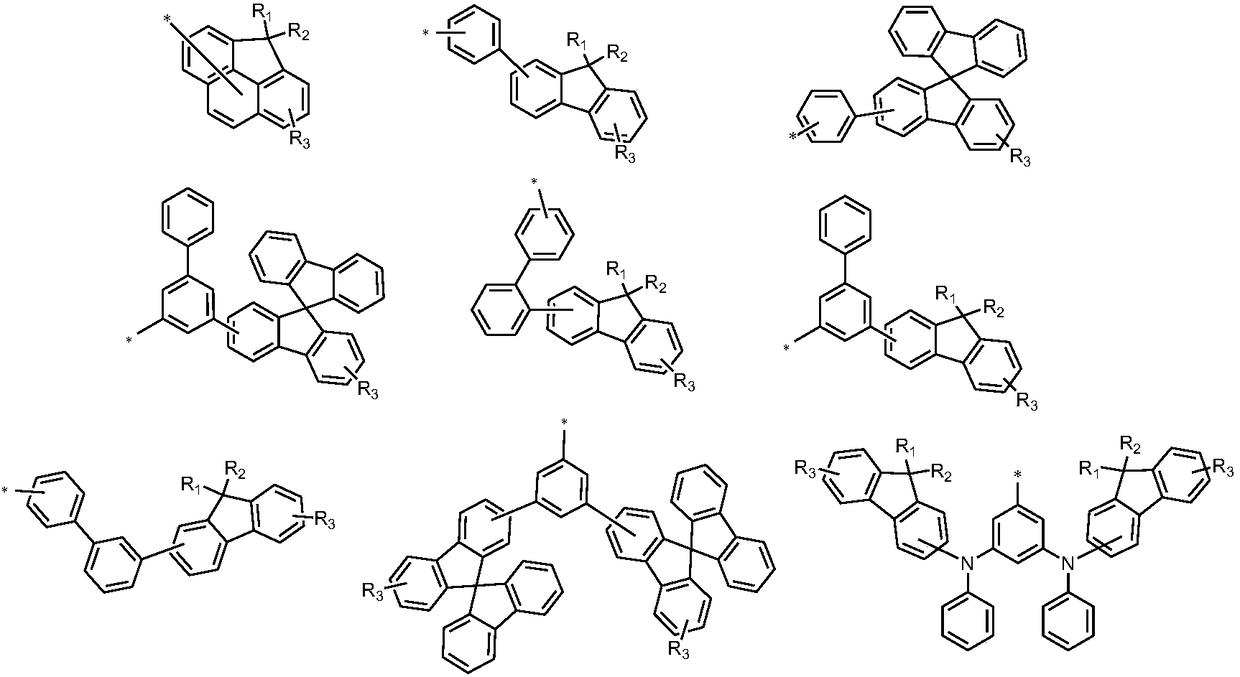

Method used

Image

Examples

Embodiment 1

[0069] [Example 1] Synthesis of Compound A1

[0070]

[0071] Synthesis of intermediate a1-1

[0072] Take 3,5-dichlorobiphenyl (9.4g, 42.4mmol) into a three-necked flask, add 100mL of THF, protect it under nitrogen, stir at -78°C for 30 minutes, then add 21mL of n-butyllithium (2.5M), and react 1 After 1 hour, add 14 g of triisopropyl borate, react at low temperature for 1 hour, and gradually return to room temperature. In the post-treatment process, 2M hydrochloric acid was added to the system to make the pH of the solution 4-5, and the liquid separation was allowed to stand. The aqueous layer was extracted with ethyl acetate, the organic layers were combined, and spin-dried to obtain intermediate a1-1 (8.2g, yield 80%).

[0073]Mass Spectrum m / z: 242.16 (calculated: 242.09). Theoretical element content (%)C 12 h 12 B 2 o 4 : C, 59.60; H, 5.00; B, 8.94; O, 26.46 The measured element content (%): C, 59.61; H, 5.02; B, 8.94; O, 26.43. The above results confirmed tha...

Embodiment 2

[0080] [Example 2] Synthesis of Compound A40

[0081]

[0082] The 2,4-dibromo-6-phenyl-1,3,5-triazine in Example 1 was replaced by an equimolar compound d, and the other steps were the same as in Example 1 to obtain the target product compound A40 . Mass Spectrum m / z: 936.26 (calculated: 936.15). Theoretical element content (%)C 69 h 49 N 3 O: C, 88.53; H, 5.28; N, 4.49; O, 1.71 Measured element content (%): C, 88.53; H, 5.26; N, 4.49; O, 1.73. The above results confirmed that the obtained product was the target product.

Embodiment 3

[0083] [Example 3] Synthesis of Compound B1

[0084]

[0085] Synthesis of intermediate b1-1

[0086] After 4H-cyclopentaphenanthrene is replaced by iodomethane, react with liquid bromine to obtain 8-bromo-4,4-dimethylcyclopentaphenanthrene. Take 8-bromo-4,4-dimethylcyclopentaphenanthrene (12.6g, 42.4mmol) into a three-necked flask, add THF 100mL, protect with nitrogen, stir at -78°C for 30 minutes, then add n-butyllithium (2.5 M) 21 mL, reacted for 1 hour, then added 7 g of triisopropyl borate, reacted at low temperature for 1 hour, and gradually returned to room temperature. In the post-treatment process, 2M hydrochloric acid was added to the system to make the pH value of the solution 4-5, and the liquid separation was allowed to stand, the aqueous layer was extracted with ethyl acetate, the organic layers were combined, and spin-dried to obtain intermediate b1-1 (8.3g, yield 75%).

[0087] Mass Spectrum m / z: 262.16 (calculated: 262.11). Theoretical element content (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com