Preparation method of TNT magnetic molecularly imprinted polymer microspheres

A magnetic molecular imprinting and polymer technology, applied in the field of nitro-based explosives detection, can solve the problems of difficult elution of template molecules, too deep embedding of binding sites, uneven binding sites, etc., and achieve good adsorption and separation. The effect of performance, uniform shape, and easy detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

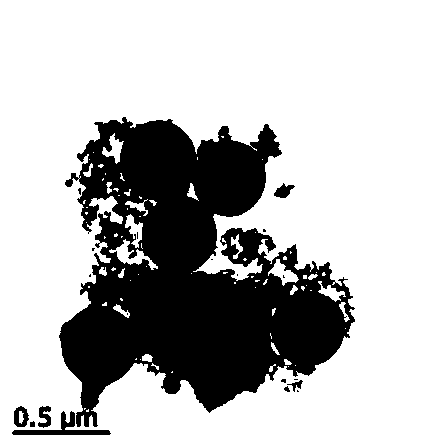

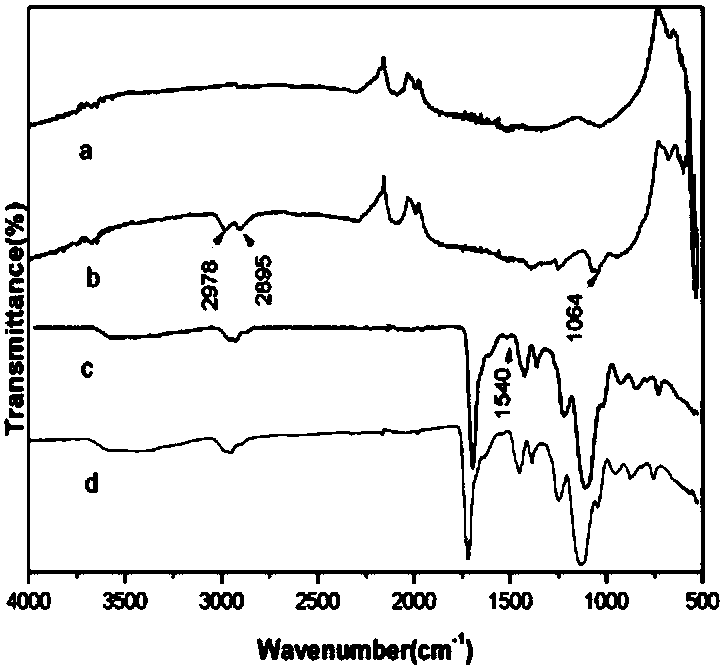

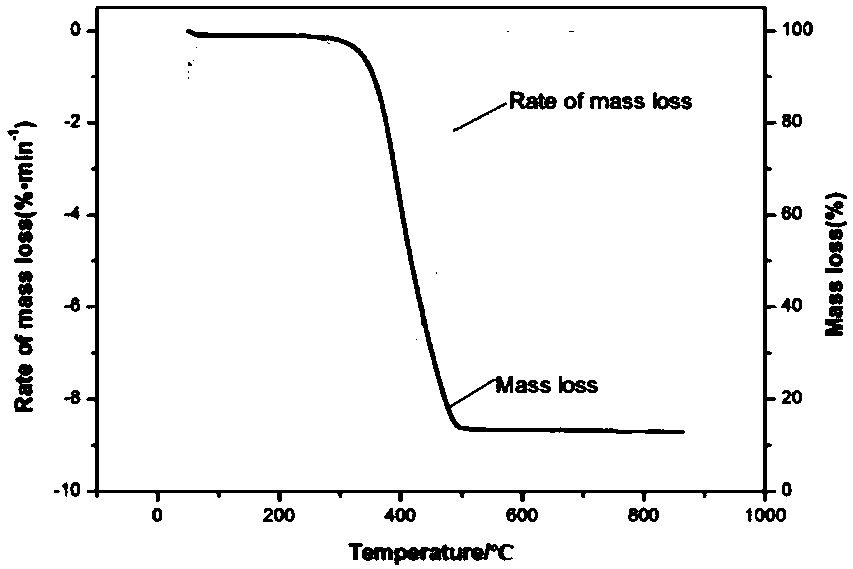

[0020] 1. Amino modified ferric oxide

[0021] First, prepare 150ml of ethanol: deionized water = 1:1 mixed solution, and place the solution in a 250ml three-neck round bottom flask. Use acetic acid to adjust the pH value of the appeal solution to 4, and accurately weigh 0.4g Fe 3 o 4 The nanoparticles are dispersed and mixed uniformly by ultrasonic in the above mixed solution. After the mixing is completed, place the flask in a water bath, stir rapidly with a stirring paddle, and add 0.5ml KH550 dropwise while stirring, deoxygenate the system with nitrogen for 10 minutes, and seal it with vacuum silicone grease. At 60°C, the reaction was stirred for 3h. After the reaction was completed, the nanoparticles were collected using a magnet, and the product was washed with deionized water several times until the pH of the eluate was neutral, and the product was vacuum-dried and collected for use.

[0022] 2. Synthesis of molecularly imprinted polymers on magnetic surfaces

[00...

Embodiment 2

[0043] 1. Amino modified ferric oxide

[0044] First, prepare 150ml of ethanol: deionized water = 1:1 mixed solution, and place the solution in a 250ml three-neck round bottom flask. Use acetic acid to adjust the pH value of the appeal solution to 3.7, and accurately weigh 0.42g Fe 3 o 4 The nanoparticles are dispersed and mixed uniformly by ultrasonic in the above mixed solution. After the mixing is completed, place the flask in a water bath, stir rapidly with a stirring paddle, and add 0.8ml KH550 dropwise while stirring, deoxygenate the system with nitrogen for 10 minutes, and seal it with vacuum silicone grease. At 60°C, the reaction was stirred for 4h. After the reaction was completed, the nanoparticles were collected using a magnet, and the product was washed with deionized water several times until the pH of the eluate was neutral, and the product was vacuum-dried and collected for use.

[0045] 2. Synthesis of molecularly imprinted polymers on magnetic surfaces

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com