A kind of preparation method and application of citric acid grafted chitosan pellets

A technology of citric acid and chitosan, applied in chemical instruments and methods, other chemical processes, water/sludge/sewage treatment, etc., to achieve the effects of low cost, good selectivity and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6

[0037] Embodiment 1-6: the preparation of citric acid grafted chitosan pellet

[0038] (1) Add the CTAB of formula dosage to 100mL distilled water, adjust the temperature to 46°C in the water bath, start stirring at 1000rpm, stir for 15min, then add chitosan (deacetylation degree ≥ 90.0%, 700,000-800,000 molecular weight), keep stirring for 40 minutes, then add the amount of citric acid used in the formula, and stir at room temperature for 5 hours to obtain a uniform and stable gel.

[0039] (2) Pour the above-mentioned gel into a 50mL burette, dropwise dropwise into 600mL of 1mol / L sodium hydroxide solution under magnetic stirring, to form wet gel balls with a particle size of 2.5-3.5mm.

[0040] (3) Vacuum freeze-dry the above-mentioned wet gel ball at -80°C for 20 h to obtain loose and porous citric acid grafted chitosan pellets.

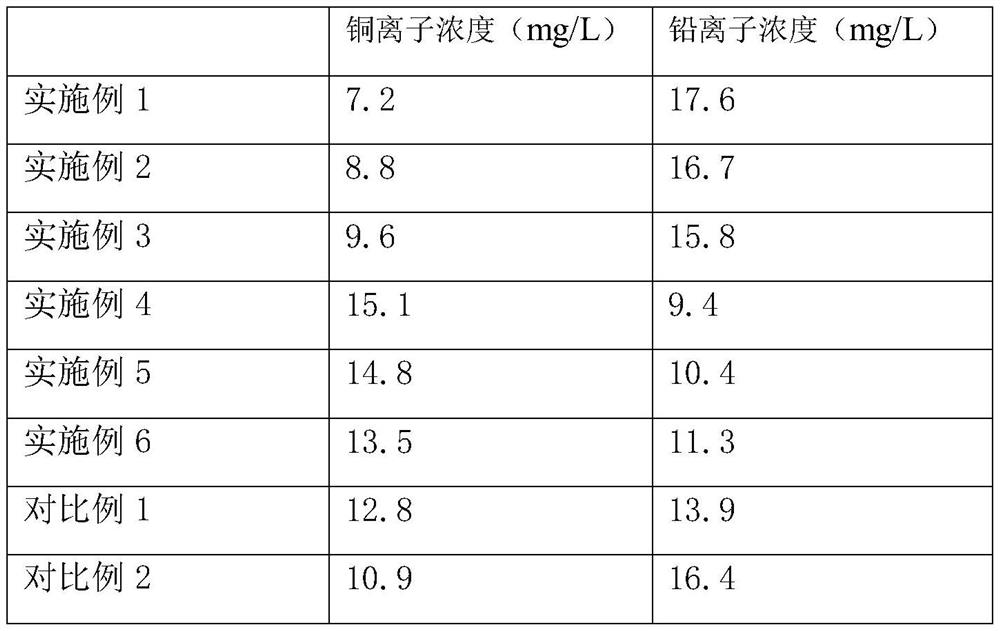

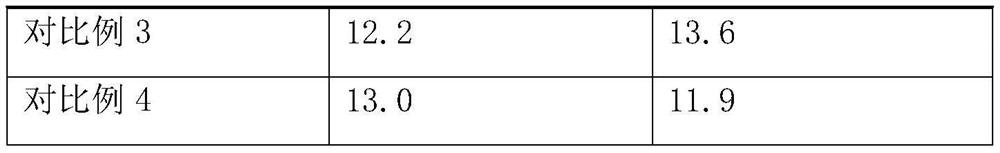

[0041] Embodiment 1-6 formula is as shown in table 1:

[0042] Table 1.

[0043] Dosage (g) Example 1 Example 2 Example 3 Ex...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com