Naphthyl polyimide magnetic composite and its preparation method and application

A naphthyl polyimide and naphthyl polyimide layer technology are applied in the field of naphthyl polyimide magnetic composite and its preparation, which can solve the problems of less research and the like, and achieve low preparation cost, reduced difficulty and high efficiency. Cost, effect of simple synthesis method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

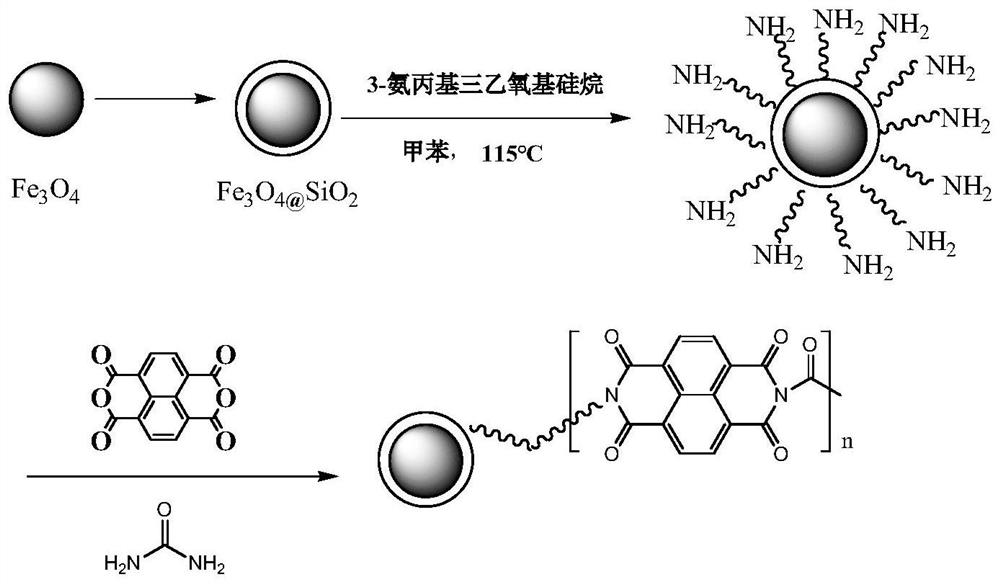

[0039] Example 1. Preparation of naphthyl polyimide magnetic composite

[0040] The preparation method of naphthyl polyimide magnetic composite comprises the following steps:

[0041] (1) Magnetic Fe 3 O 4 Synthesis of Nanoparticles:

[0042] Weigh 2.7g FeCl 3 ·6H 2 O solid in a 100mL beaker, add 80mL ethylene glycol, sonicate to FeCl 3 ·6H 2 O solid dissolved solution was a transparent liquid, then 7.2g anhydrous sodium acetate and 2.0g polyethylene glycol were added, ultrasonicated for 20min, the solution was yellow-brown, and contained a large amount of yellow flocs; the obtained mixture was transferred to the autoclave , reacted at 200 °C for 12 h, cooled to room temperature, and washed the Fe generated by the reaction with ethanol and double distilled water in turn. 3 O 4 Nanoparticles, repeated three times, Fe 3 O 4 Nanoparticles were stored in absolute ethanol for later use.

[0043] (2) Magnetic Fe 3 O 4 @SiO 2 Synthesis of Nanoparticles:

[0044] Weigh ...

Embodiment 2

[0054] Embodiment 2, the adsorption performance test of naphthyl polyimide magnetic composite:

[0055] 4 mg of naphthyl polyimide magnetic complex was taken, and 5 mL of Sudan red mixed standard solution with a concentration of 0.2 μg / mL was added to investigate the effect of ultrasonic time on the adsorption efficiency of Sudan red. like Image 6 As shown, the adsorption efficiency of the naphthyl polyimide magnetic composite of the present invention to the Sudan red compound increases with the extension of the adsorption time, and the adsorption efficiency reaches more than 90% at 8 min.

Embodiment 3

[0056] Embodiment 3. Comparison of naphthyl polyimide magnetic composite and commercial extraction material:

[0057] In order to investigate the extraction effect of naphthyl polyimide magnetic complex on Sudan red, six commercial extractants were selected, including neutral alumina, C18, NH 2 , MCX, HLB, and MAX, were compared. Weigh 3.0 mg of the above six extractants and add them to the Sudan red solution (0.2 μg / mL, 5.00 mL), and after adsorption for 10 min, pipette the extracted Sudan red solution for sample analysis, and calculate the adsorption efficiency. like Figure 7 As shown, the adsorption efficiency of the naphthyl polyimide magnetic composite for Sudan red is much higher than that of commercial adsorbents, indicating that it has unique advantages in the adsorption of Sudan dyes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com