a use of co 2 Method for preparing amidoxime-functionalized hollow porous polymer microspheres as emulsion templates

A porous polymer, emulsion template technology, applied in the direction of alkali metal compounds, chemical instruments and methods, alkali metal oxides/hydroxides, etc. Capacity, high adsorption capacity, the effect of simplifying the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] (1) Preparation of silica nanoparticles;

[0050] use Method to manufacture silica nanoparticles: In a flask, add 8.735g TEOS to 180mL of ethanol, after heating in a water bath to 35°C, add 10mL of NH 3 ·H 2 A mixed solution of O and 9.48g water; then the formed mixed solution was reacted for 3.0h under magnetic stirring; after the reaction was completed, the product was collected by centrifugation and washed three times with deionized water and ethanol respectively; 200 nm silica nanoparticles;

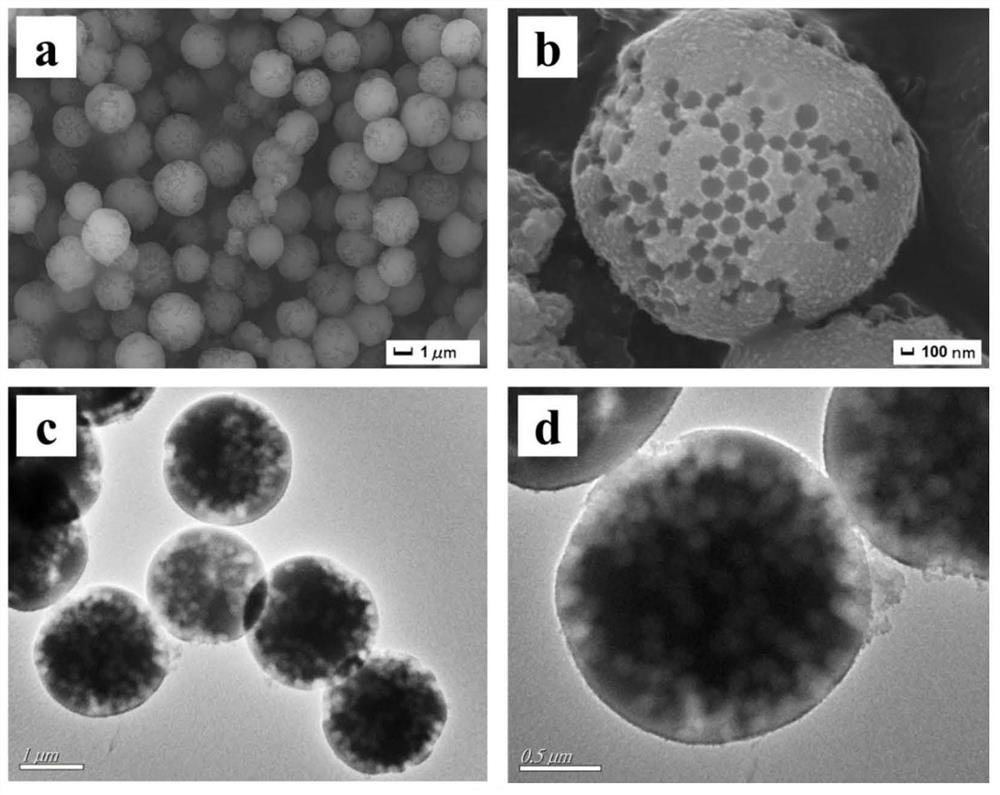

[0051] (2) preparation of hollow porous melamine resin;

[0052] At 85°C, 1.26g of melamine was added to 3.0mL of a mixed solution of 37% formaldehyde and 25% glutaraldehyde (v / v, 2:1), and then 2.0M Na 2 CO 3 Adjust the pH of the solution to 9.5, stir at 1500rpm, and continue to react for 3.0min after the solution turns from milky white to clear; then, add 10mL of 10wt% silica water dispersion under stirring, and continue to react for 20min; then, cool the solution To ...

Embodiment 2

[0064] (1) Preparation of silica nanoparticles;

[0065] use Method to manufacture silica nanoparticles: In a flask, add 8.0g TEOS to 170mL ethanol, heat in a water bath to 30°C, then add 9.0mL NH 3 ··H 2 O and 9.0 g H 2 O mixed solution; then the formed mixed solution was reacted under magnetic stirring for 2.0h; after the reaction was completed, the product was collected by centrifugation and washed three times with deionized water and ethanol respectively; after drying, a silica with a diameter of about 200nm could be obtained Nanoparticles.

[0066] (2) preparation of hollow porous melamine resin;

[0067] Add 1.0 g of melamine to 2.0 mL of a mixed solution of 37% formaldehyde and 25% glutaraldehyde (v / v, 2:1) at 80°C, and then use 2.0M Na 2 CO 3 The pH of the solution was adjusted to 9.0, stirred at 1200rpm, and the reaction was continued for 4.0min after the solution changed from milky white to clear; then, 5.0 mL of 10wt% silica aqueous dispersion was added under ...

Embodiment 3

[0072] (1) Preparation of silica nanoparticles;

[0073] use Method to manufacture silica nanoparticles: In a flask, add 10g TEOS to 190mL ethanol, heat in a water bath to 40°C, then add 11mL NH 3 ·H 2 O and 10g H 2 A mixed solution of O. Then the resulting mixed solution was reacted for 4.0 h under magnetic stirring. After the reaction was completed, the product was collected by centrifugation and washed three times with deionized water and ethanol respectively. After drying, silica nanoparticles with a diameter of about 200 nm can be obtained.

[0074] (2) preparation of hollow porous melamine resin;

[0075] At 90°C, 2.0 g of melamine was added to 4.0 mL of a mixed solution of 37% formaldehyde and 25% glutaraldehyde (v / v, 2:1), and then 2.0 M Na 2 CO 3 The pH of the solution was adjusted to 10.0, stirred at 1600 rpm, and the reaction was continued for 5.0 min after the solution changed from milky white to clear; then, 15 mL of 10 wt % silica aqueous dispersion was ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com