Preparation method for lysozyme antibacterial film

An antibacterial film and lysozyme technology, applied in the field of antibacterial materials, can solve the problems of short antibacterial time, short sterilization time, complex process, etc., and achieve the effects of strengthening mechanical properties, enhancing sterilization durability, and ensuring solubility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

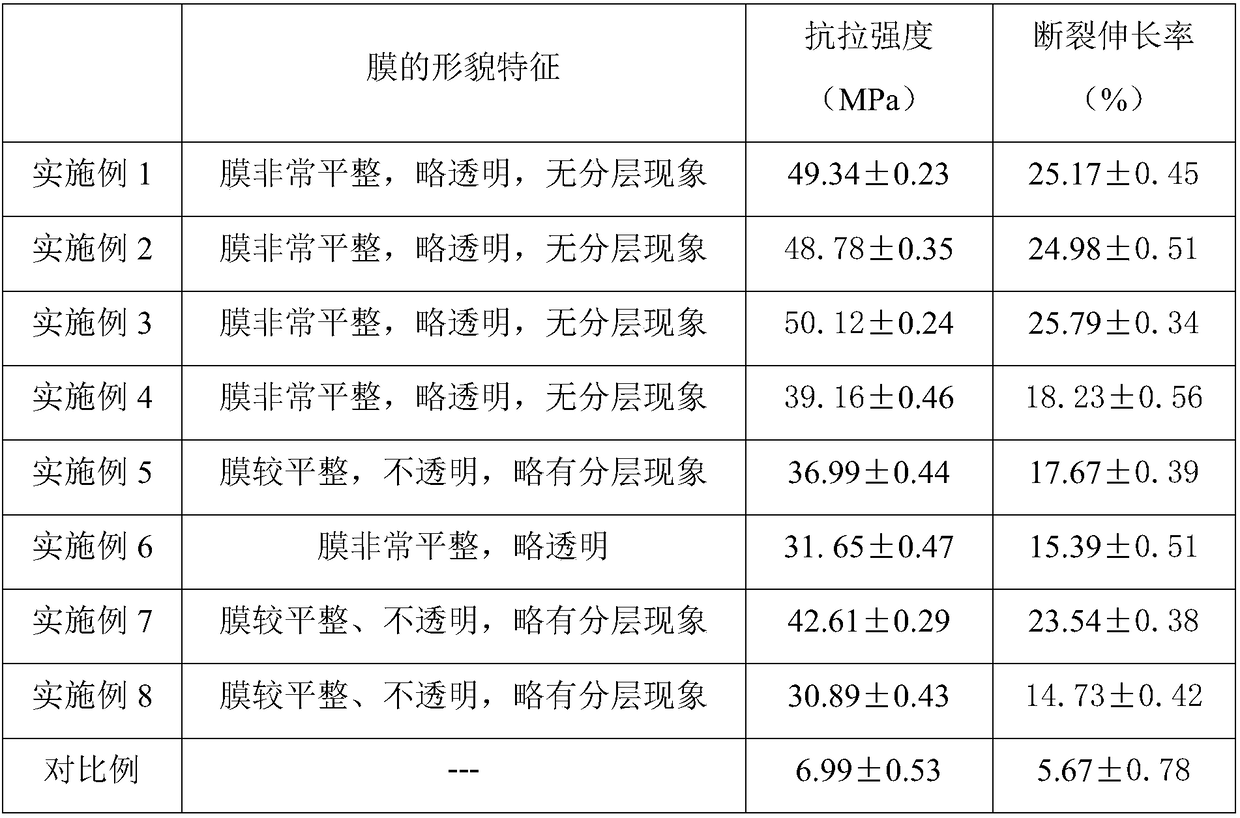

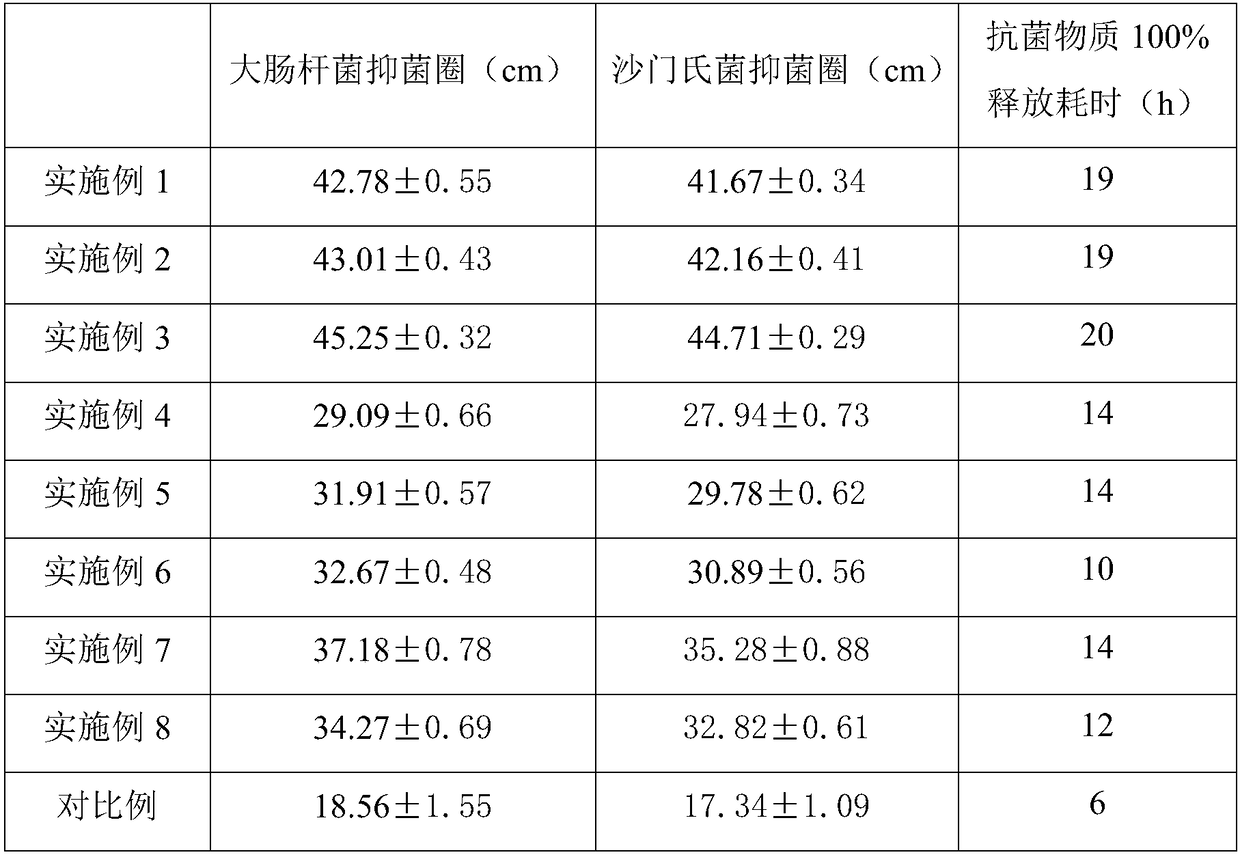

Examples

Embodiment 1

[0035] A preparation method of lysozyme antibacterial film, it comprises the following steps:

[0036] Step 1: In parts by weight, take 0.5 parts of cactus and 0.8 parts of aloe, wash, peel and chop them respectively, add 15 parts of distilled water, heat to 100°C and boil for 2 hours, filter while hot to obtain For the first filtrate and the first filter residue, add 0.01 part of nano-carbon powder and 0.005 part of nano-eggshell powder to the first filtrate and stir until they are evenly mixed to obtain the first mixture; take 0.3 part of peppermint through steam distillation The method is to obtain peppermint essential oil and distillation residue; add 0.003 parts of nano-carbon powder and 0.001 part of nano-eggshell powder to the peppermint essential oil and mix to obtain a second mixture;

[0037] Step 2. Mix the first filter residue and the distillation residue with 3 parts of beer and 10 parts of ethanol and stir evenly, then place it in an environment with a temperatur...

Embodiment 2

[0047] A preparation method of lysozyme antibacterial film, it comprises the following steps:

[0048] Step 1: In parts by weight, take 1 part of cactus and 1.2 parts of aloe, wash, peel and chop them respectively, add 20 parts of distilled water, heat to 110 ° C and boil for 3 hours, filter while hot, and obtain For the first filtrate and the first filter residue, add 0.05 parts of nano-carbon powder and 0.008 parts of nano-eggshell powder to the first filtrate and stir until they are evenly mixed to obtain the first mixture; take 0.5 parts of peppermint through steam distillation The method is to obtain peppermint essential oil and distillation residue; add 0.005 parts of nano-carbon powder and 0.003 parts of nano-eggshell powder to the peppermint essential oil and mix to obtain a second mixture;

[0049] Step 2. Mix the first filter residue and the distillation residue with 5 parts of beer and 15 parts of ethanol and stir evenly, then place it in an environment with a tempe...

Embodiment 3

[0059] A preparation method of lysozyme antibacterial film, it comprises the following steps:

[0060] Step 1. In parts by weight, take 0.8 parts of cactus and 1.0 part of aloe, wash, peel and chop them respectively, add 18 parts of distilled water, heat to 105°C and boil for 2.5 hours, filter while hot, Obtain the first filtrate and the first filter residue, add 0.03 parts of nano-carbon powder and 0.007 parts of nano-eggshell powder to the first filtrate and stir until they are evenly mixed to obtain the first mixture; get 0.4 parts of mint through steam Distillation method to obtain peppermint essential oil and distillation residue; add 0.004 part of nano-carbon powder and 0.002 part of nano-eggshell powder to the peppermint essential oil and mix to obtain the second mixture;

[0061] Step 2. Mix the first filter residue and the distillation residue with 4 parts of beer and 13 parts of ethanol and stir evenly, then place it in an environment with a temperature of -25°C and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com