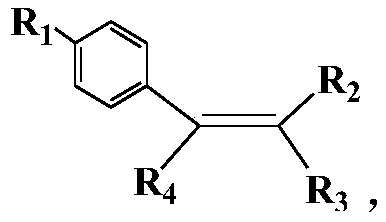

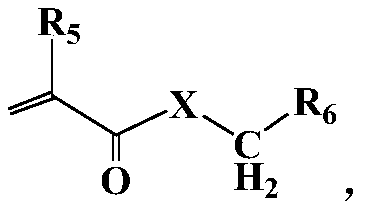

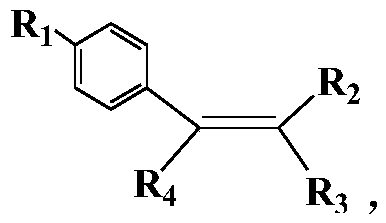

Aromatic ring polycarboxylate water reducing agent mother liquid and preparation method and application thereof

A technology of polycarboxylic acid and water reducing agent, applied in the field of concrete admixtures, can solve the problems of moldy concrete loss and excessive speed, and achieve the effect of enhancing the slump retention ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] In parts by weight, 16 parts of a-1-1 and 30 parts of water are prepared into A material liquid; 8 parts of a-2-3, 8 parts of a-3-2 and 15 parts of water are prepared into B material liquid; 1 part of L-ascorbic acid and 30 parts of water are prepared into C material liquid; 0.5 part of sodium methacrylate and 20 parts of water are prepared into D material liquid; 200 parts of isopentenyl polyoxyethylene ether, 2 parts of a-3 -2. Add 0.9 parts of hydrogen peroxide and 139 parts of water into the reaction vessel, adjust the temperature to 60°C, and stir to dissolve it; at the same time, add A material liquid, B material liquid, C material liquid and D material liquid dropwise to react; react for 1h After that, cool down to 35°C and continue to react for 2 hours; after all the feed liquids are added dropwise, keep warm for 1.5 h to obtain the 50% concentration aromatic ring polycarboxylate superplasticizer mother liquid; among them, the drop-adding time of A feed liquid is...

Embodiment 2

[0047] In parts by weight, 10 parts of a-1-2 and 25 parts of water are prepared into A material liquid; 5 parts of a-2-1, 5 parts of a-3-3 and 10 parts of water are prepared into B material liquid; 0.3 parts of sodium bisulfite and 25 parts of water are prepared into material liquid C; 0.7 parts of sodium hypophosphite and 25 parts of water are prepared into material liquid D. Add 200 parts of isopentenyl polyoxyethylene ether, 3 parts of a-3-3, 1.1 parts of ammonium persulfate, and 140 parts of water into the reaction vessel, adjust the temperature to 55°C, and stir to dissolve it; at the same time, add material A dropwise Liquid, B material liquid, C material liquid and D material liquid were reacted; after 1.5 hours of reaction, the temperature was lowered to 40°C, and the reaction was continued for 2 hours; Polycarboxylate superplasticizer mother liquor; wherein, the dropping time of material A is 1h, the dropping time of B is 3h, and the dropping time of C and D is 3h10mi...

Embodiment 3

[0049] In parts by weight, 8 parts of a-1-3 and 20 parts of water are prepared into A material liquid; 6 parts of a-2-2, 6 parts of a-3-4 and 13 parts of water are prepared into B material liquid; 0.2 parts of sodium formaldehyde sulfoxylate and 20 parts of water are prepared into C material solution; 1 part of sodium formate and 30 parts of water are prepared into D material solution. Add 200 parts of isopentenyl polyoxyethylene ether, 2 parts of a-3-4, 0.7 parts of sodium persulfate, and 142 parts of water into the reaction vessel, adjust the temperature to 65°C, and stir to dissolve it; at the same time, add material A dropwise Liquid, B material liquid, C material liquid and D material liquid were reacted; after 1 hour of reaction, the temperature was lowered to 45°C, and the reaction was continued for 1.5 hours; Polycarboxylate superplasticizer mother liquor; wherein, the dropping time of material A is 0.75h, the dropping time of B is 3h, and the dropping time of C and D ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com