Method for preparing nanometal particle/metal organic frame composite antibacterial cellulose fibers

A technology of metal-organic frameworks and nano-metal particles, which is applied in fiber treatment, plant fiber, biochemical fiber treatment, etc., can solve the problems of weak mutual bonding and easy shedding, and achieve antibacterial performance, high efficiency and long-lasting antibacterial performance, long-lasting The effect of antimicrobial properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

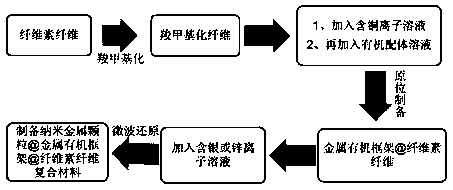

[0035] see figure 1 , the fiber in this experiment is full-bleached bamboo pulp.

[0036] The method for composite antibacterial cellulose fiber of nanometer metal particles / metal organic framework comprises the following steps:

[0037] First, the whole bleached bamboo pulp is beaten, and when the slurry concentration reaches 1%, add 30wt% sodium chloroacetate, stir for 10min, and then place it in a water bath at 30°C for 6h; then add 10wt% sodium hydroxide solution, and Mix and stir for 10 minutes; place the treated carboxymethylated cellulose fibers for 18 hours, and finally wash them with absolute ethanol at room temperature until the fibers are neutral to obtain carboxymethylcellulose;

[0038] Then, the carboxymethylated cellulose fibers prepared above were alternately soaked in 1nM copper nitrate aqueous solution and 1nM trimesic acid ethanol solution for 10 minutes each, and this was repeated alternately for 1 time, and HKUST was loaded on the fiber substrate. -1, th...

Embodiment 2

[0041] The fiber used in this experiment was fully bleached bamboo pulp.

[0042] The method for composite antibacterial cellulose fiber of nanometer metal particles / metal organic framework comprises the following steps:

[0043] First, the whole bleached bamboo pulp was beaten, and when the pulp concentration reached 2%, 40wt% sodium chloroacetate was added, stirred for 15min, and then placed in a water bath at 40°C for 5h; then 20wt% sodium hydroxide solution was added, Mix and stir for 15 minutes; place the treated carboxymethylated cellulose fiber for 18 hours, and finally wash it with absolute ethanol at room temperature until the fiber is neutral to obtain carboxymethylcellulose;

[0044] Then, the carboxymethylated cellulose fibers prepared above were soaked in the acetic acid solution of 10nM copper acetate and the ethanol solution of 10nM trimesic acid in alternating circulation respectively for 15min, so repeated alternately dipping 4 times, and loaded on the fiber sub...

Embodiment 3

[0047] The fiber in this experiment was cotton dissolving pulp.

[0048] The method for composite antibacterial cellulose fiber of nanometer metal particles / metal organic framework comprises the following steps:

[0049] First, the cotton dissolving pulp was beaten, and when the pulp concentration reached 3%, 50wt% sodium chloroacetate was added, stirred for 20min, and then placed in a water bath at 40°C for 5h; then 20wt% sodium hydroxide solution was added, and Mix and stir for 20min. Place the treated carboxymethylated cellulose fibers for 20 hours, and finally wash them with absolute ethanol at room temperature until the fibers are neutral to obtain carboxymethylcellulose;

[0050] Then, the carboxymethylated cellulose fibers prepared above were alternately soaked in the ethanol solution of 20nM copper nitrate and the DMF solution of 20nM trimesic acid for 20min respectively, and repeated alternately dipping 6 times in this way, and loaded on the fiber substrate HKUST-1,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com