Performance test system for fuel-driven compressor unit

A compressor unit and testing system technology, applied in the testing of machines/structural components, measuring devices, instruments, etc., can solve problems affecting the accuracy of the performance monitoring system, and achieve accurate and reliable calculations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

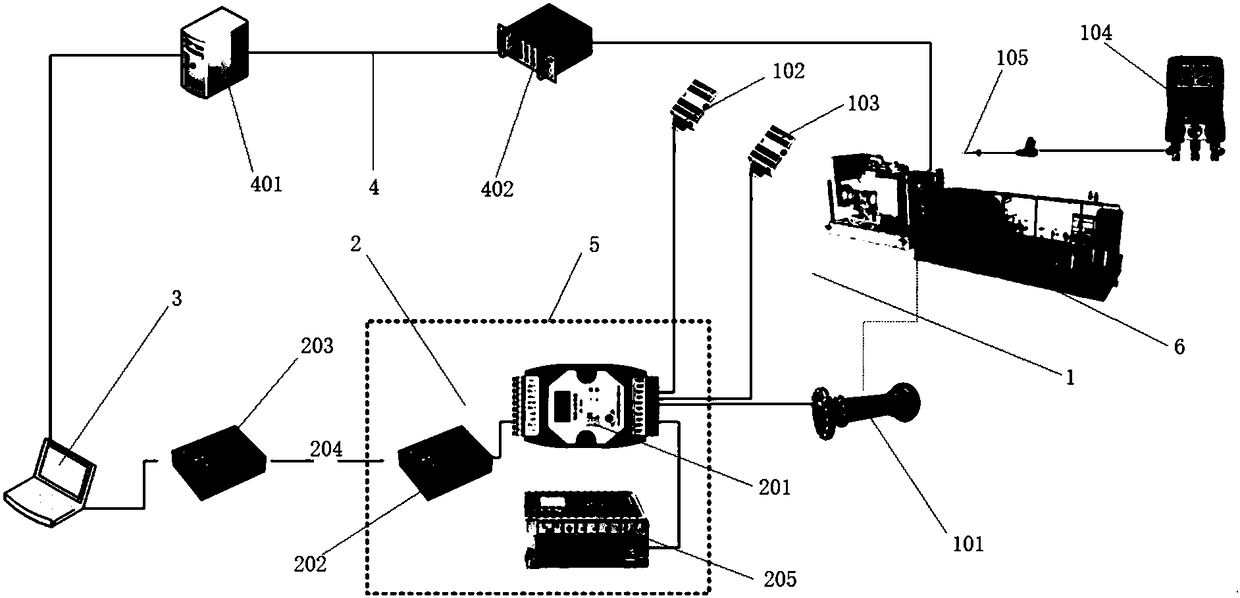

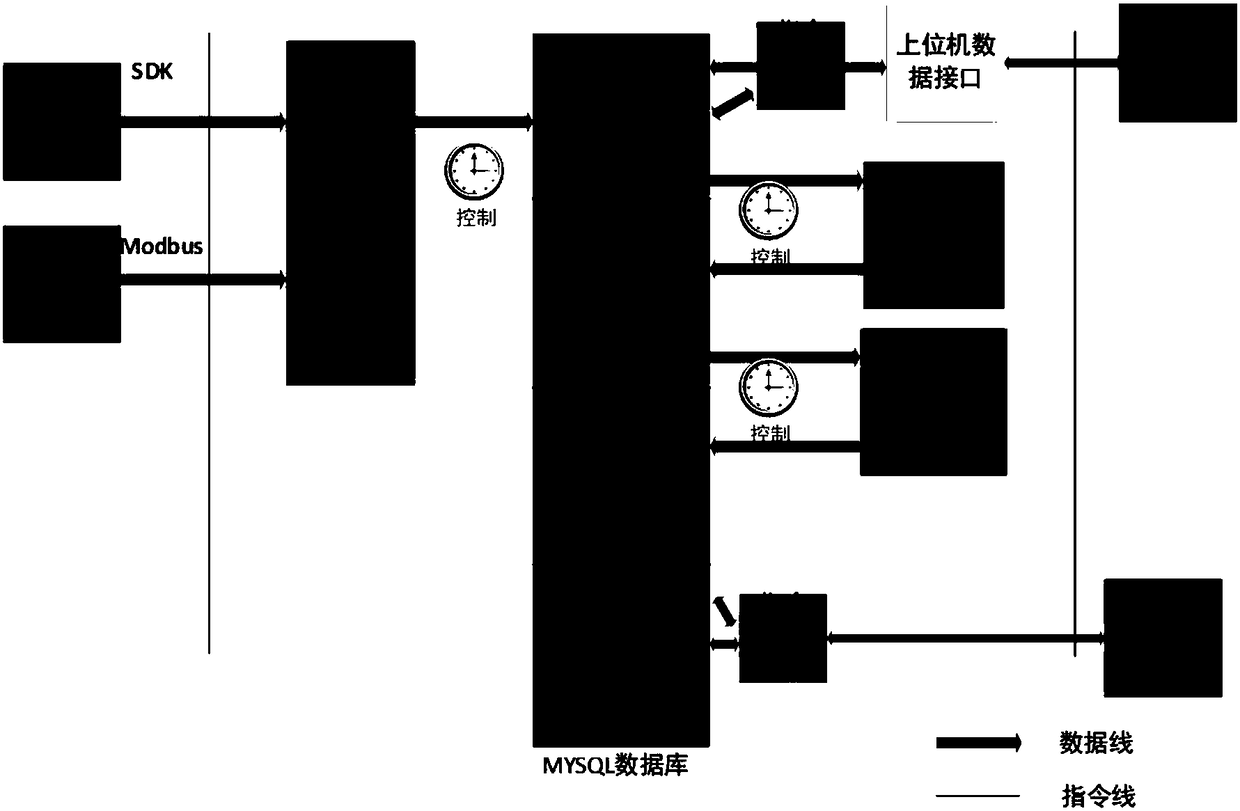

[0028] Such as figure 1 As shown, this embodiment includes a signal acquisition module 1, a signal transmission module 2, and a performance calculation module 3. The signal acquisition module 1 includes a torque meter 101, a temperature sensor 102, a humidity sensor 103, and a flue gas analyzer 104. The flue gas analyzer 104 also has a flue gas probe 105. The signal transmission module 2 includes an analog quantity converter 201, a first optical fiber signal converter 202, a second optical fiber signal converter 203, and an optical fiber 204. The signal acquisition module 1 and the signal transmission module 2 also include a number of necessary power supply devices 205. The analog quantity converter 201, the first optical fiber signal converter 202, and the power supply device 205 are collectively installed in an explosion-proof box 5. The explosion-proof box 5 is arranged near the combustion-driven compressor unit 6. The performance calculation module 3 includes a portable c...

Embodiment 2

[0038] In the field test experiment, first install the acquisition system for several sensor signals of the combustion-driven compressor unit 6 that needs to be tested for performance to collect the signals of the ambient pressure, ambient humidity, flue gas analyzer and torque meter, and then the combustion-driven compressor unit 6 The original measurement point data is input to the test system through other data interfaces, and the software and hardware test system is installed, and the on-site debugging is performed to prepare for the test.

[0039] The main idea of the performance test is to use the speed control strategy of the gas turbine control system. Under the premise of safe operation, select the largest speed range as possible, and in turn make the unit run at the set speed, and start the experiment after the unit is stable.

[0040] Regarding the test speed and range, some parameter requirements are: the lowest running speed of the power turbine: 3965r / min, the normal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com