A kind of preparation method of graphene/phenylenediamine flexible composite membrane electrode

A phenylenediamine and graphene technology, which is applied in the field of membrane electrode material preparation, can solve the problem that the phenylenediamine composite flexible composite membrane electrode has low capacitance performance, affects the full utilization of graphene specific surface area, and affects phenylenediamine and graphene. Effective compounding and other issues, to achieve the effect of shortening the transmission distance, easy transmission, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

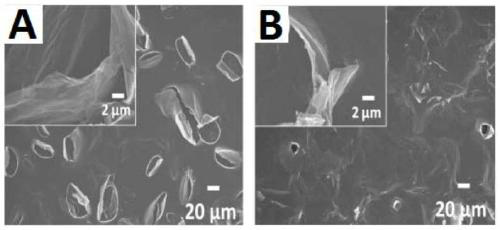

[0027] Example 1 Preparation of Graphene / Phenylenediamine Flexible Composite Membrane Electrode

[0028] Preparation of graphene oxide / phenylenediamine / urea composite membrane: According to the improved Hummers method, graphite was used as raw material to prepare a graphene oxide aqueous solution with a concentration of 3 mg / mL. First, 1 mL of 3 mg / mL graphene oxide aqueous solution and 15 mg of urea aqueous solution were ultrasonically homogenized. Then, take 0.44ml of 16.0mg / ml p-phenylenediamine aqueous solution and slowly drop into the above mixed solution for ultrasonic mixing and pour it into a polytetrafluoroethylene cover with a diameter of 2.8cm and dry it at 30°C to obtain graphene oxide / phenylenediamine Amine / urea composite membrane a.

[0029] For comparison, slowly drop 0.44ml of 16.0mg / ml p-phenylenediamine aqueous solution into 1mL of 3mg / mL graphene oxide aqueous solution and ultrasonically mix, and pour it into a polytetrafluoroethylene cap with a diameter of...

Embodiment 2

[0032] Embodiment 2 Preparation of graphene / phenylenediamine flexible composite membrane electrode

[0033] Preparation of graphene oxide / phenylenediamine / urea composite membrane: According to the improved Hummers method, graphite was used as raw material to prepare a graphene oxide aqueous solution with a concentration of 3 mg / mL. First, 1 mL of 3 mg / mL graphene oxide aqueous solution and 10 mg of urea aqueous solution were ultrasonically homogenized. Then, take 0.44ml of 16.0mg / ml p-phenylenediamine aqueous solution and slowly drop into the above mixed solution for ultrasonic mixing and pour it into a polytetrafluoroethylene cover with a diameter of 2.8cm and dry it at 30°C to obtain graphene oxide / phenylenediamine Amine / urea composite membrane.

[0034] Preparation of Graphene / Phenylenediamine Flexible Composite Membrane Electrode: Same as Example 1.

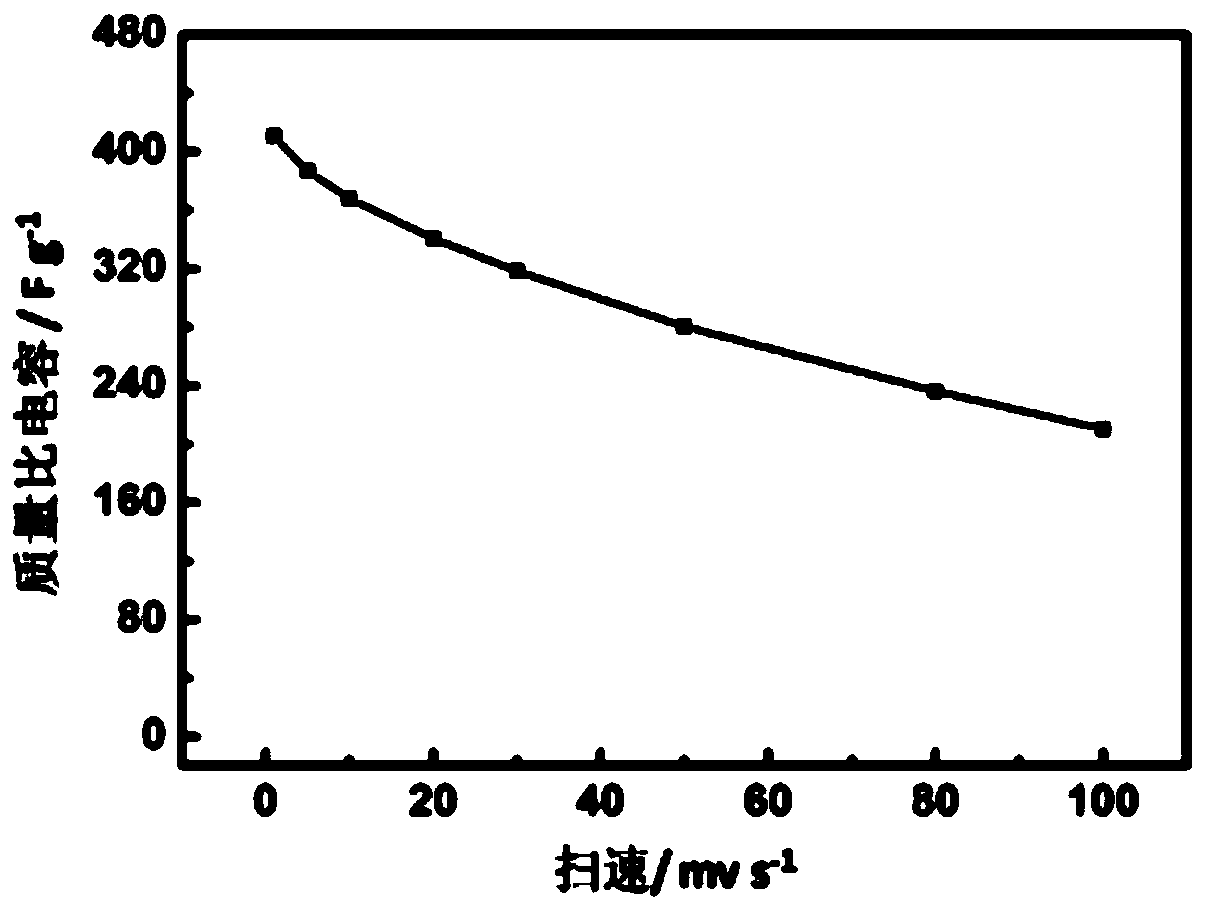

[0035] A symmetrical supercapacitor was assembled with the prepared graphene / phenylenediamine flexible composite film as ...

Embodiment 3

[0036] Example 3 Preparation of Graphene / Phenylenediamine Flexible Composite Membrane Electrode

[0037] Preparation of graphene oxide / phenylenediamine / urea composite membrane: According to the improved Hummers method, graphite was used as raw material to prepare a graphene oxide aqueous solution with a concentration of 3 mg / mL. First, 1 mL of 3 mg / mL graphene oxide aqueous solution and 20 mg of urea aqueous solution were ultrasonically homogenized. Then, take 0.44ml of 16.0mg / ml p-phenylenediamine aqueous solution and slowly drop into the above mixed solution for ultrasonic mixing and pour it into a polytetrafluoroethylene cover with a diameter of 2.8cm and dry it at 30°C to obtain graphene oxide / phenylenediamine Amine / urea composite membrane.

[0038] Preparation of Graphene / Phenylenediamine Flexible Composite Membrane Electrode: Same as Example 1. A symmetrical supercapacitor was assembled with the prepared graphene / phenylenediamine flexible composite film as the electrod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com