Preparation method of hydrogen fuel cell catalyst

A fuel cell and catalyst technology, applied in battery electrodes, circuits, electrical components, etc., can solve problems such as low cost, achieve low cost, improve utilization rate, and solve catalyst resource problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

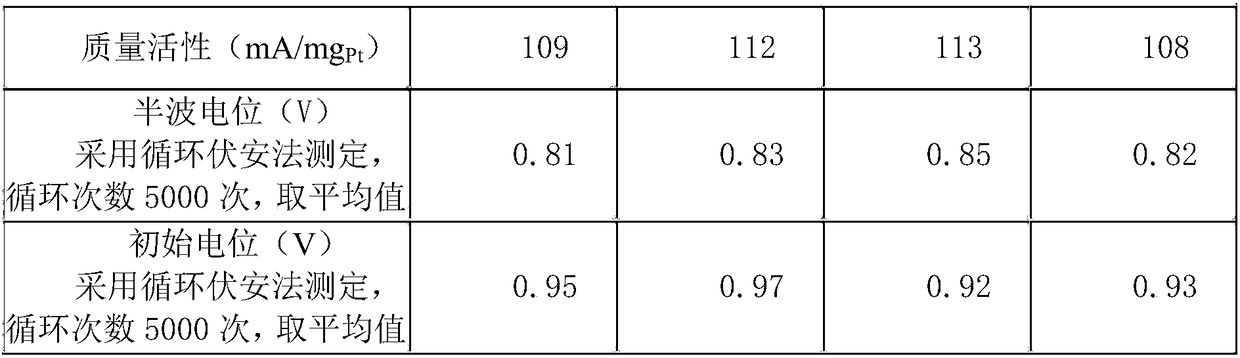

Embodiment 1

[0028] Dissolve carbon nanotubes in water and ultrasonically disperse to obtain a dispersion. Adjust the pH of the dispersion to 6 with acetic acid, add ethylenediamine, stir evenly, and then reflux the solution at 65°C for 5 hours, filter, wash, Dry to obtain a carbon carrier; wherein the mass ratio of carbon nanotubes to ethylenediamine is 1:10, the diameter of the carbon nanotubes is between 10nm and 25nm, and the concentration of the carbon nanotube dispersion is 0.15mg / ml; weigh The above-mentioned carbon carrier, sodium dodecylsulfonate, tripotassium citrate and sodium acetate are added into the mixed alcohol solution, and dispersed uniformly to obtain a mixed solution containing the carbon carrier. Wherein, the mass ratio of the carbon carrier, sodium dodecylsulfonate, tripotassium citrate, sodium acetate and mixed alcohol solution is 1:0.2:4:2:1.5. The mixed alcohol solution is formed by mixing ethylene glycol and isopropanol; the volume ratio of the ethylene glycol an...

Embodiment 2

[0036] Dissolve carbon nanotubes in water and ultrasonically disperse to obtain a dispersion, adjust the pH of the dispersion to 6 with acetic acid, add ethylenediamine, stir evenly, then reflux the solution at 65°C for 6 hours, filter, wash, drying to obtain a carbon carrier; wherein the mass ratio of carbon nanotubes to ethylenediamine is 1:12, the diameter of the carbon nanotubes is between 10nm and 25nm, and the concentration of the carbon nanotube dispersion is 0.15-0.5mg / ml; The above-mentioned carbon carrier, sodium dodecylsulfonate, tripotassium citrate and sodium acetate are weighed and added into the mixed alcohol solution, and dispersed uniformly to obtain a mixed solution containing the carbon carrier. Wherein, the mass ratio of the carbon carrier, sodium dodecylsulfonate, tripotassium citrate, sodium acetate and mixed alcohol solution is 1:0.5:1.5:2:1.5. The mixed alcohol solution is formed by mixing ethylene glycol and isopropanol; the volume ratio of the ethylen...

Embodiment 3

[0044] Dissolve carbon nanotubes in water and ultrasonically disperse to obtain a dispersion, adjust the pH of the dispersion to 7 with acetic acid, add ethylenediamine, stir evenly, then reflux the solution at 70°C for 7 hours, filter, wash, Dry to obtain a carbon carrier; wherein the mass ratio of carbon nanotubes to ethylenediamine is 1:12, the diameter of the carbon nanotubes is between 10nm and 25nm, and the concentration of the carbon nanotube dispersion is 0.45mg / ml; weigh The above-mentioned carbon carrier, sodium dodecylsulfonate, tripotassium citrate and sodium acetate are added into the mixed alcohol solution, and dispersed uniformly to obtain a mixed solution containing the carbon carrier. Wherein, the mass ratio of the carbon carrier, sodium dodecylsulfonate, tripotassium citrate, sodium acetate and mixed alcohol solution is 1:1:5:2:2. The mixed alcohol solution is formed by mixing ethylene glycol and isopropanol; the volume ratio of the ethylene glycol and isopro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com