Lithium ion battery electrolyte and lithium ion battery comprising same

A lithium-ion battery and electrolyte technology, applied in secondary batteries, circuits, electrical components, etc., can solve the problems of difficult application of high-nickel ternary power materials, reducing battery life, and damaging the passive film of active materials, etc. Achieve the effect of improving high-temperature storage performance and cycle performance, improving high-temperature performance, and inhibiting battery gas production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

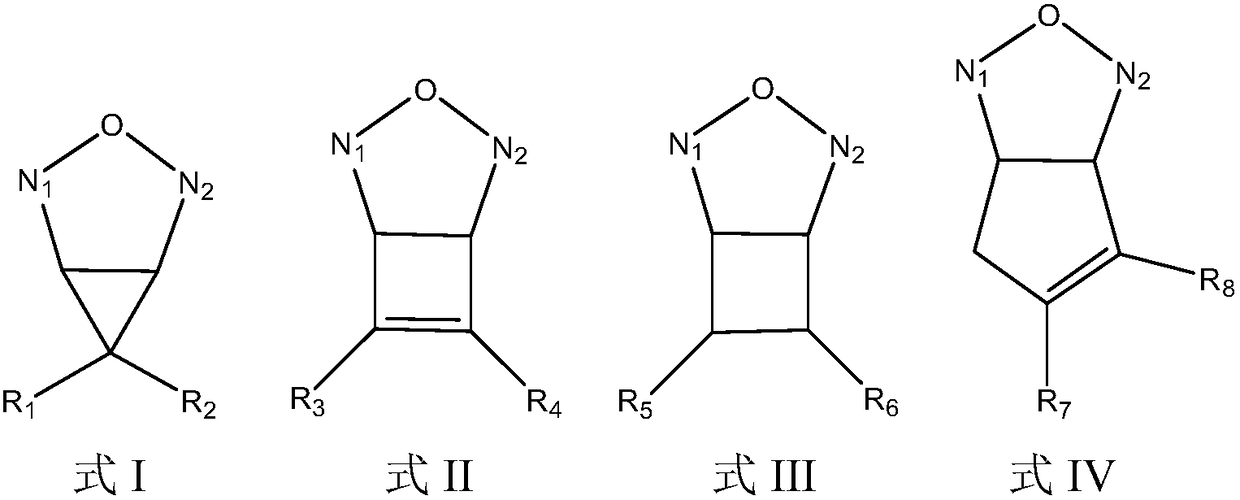

Method used

Image

Examples

Embodiment 1

[0031] Electrolyte preparation:

[0032] In a glove box filled with argon (moisture content 3 , and then slowly add a lithium salt with a mass fraction of 12.5%, and stir until it is completely dissolved to obtain the lithium ion battery electrolyte of Example 1.

[0033] Preparation of lithium-ion batteries:

[0034] The positive electrode active material LiNi 0.6 co 0.2 mn 0.2 o 2 , the conductive agent acetylene black, and the binder polyvinylidene fluoride are fully stirred and mixed in the N-methylpyrrolidone system according to the mass ratio of 95:3:2, and then coated on the aluminum foil, dried, and cold-pressed to obtain the positive electrode sheet .

[0035] After the negative electrode active material LA1, the conductive agent acetylene black, the binder styrene-butadiene rubber, and the thickener carboxymethyl cellulose sodium are fully stirred and mixed in the deionized water solvent system according to the mass ratio of 96:2:1:1, Coating on copper foil, dr...

Embodiment 2~40

[0038] Embodiment 2~40 and comparative example 1~4

[0039] Electrolyte preparation:

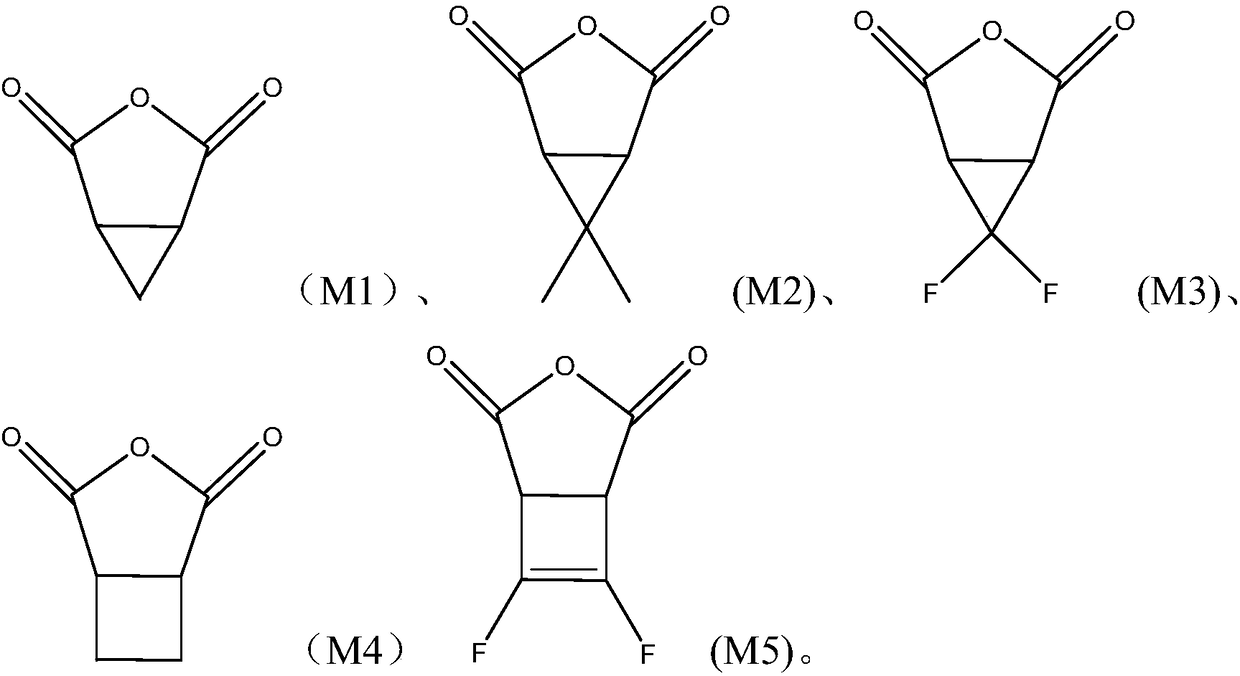

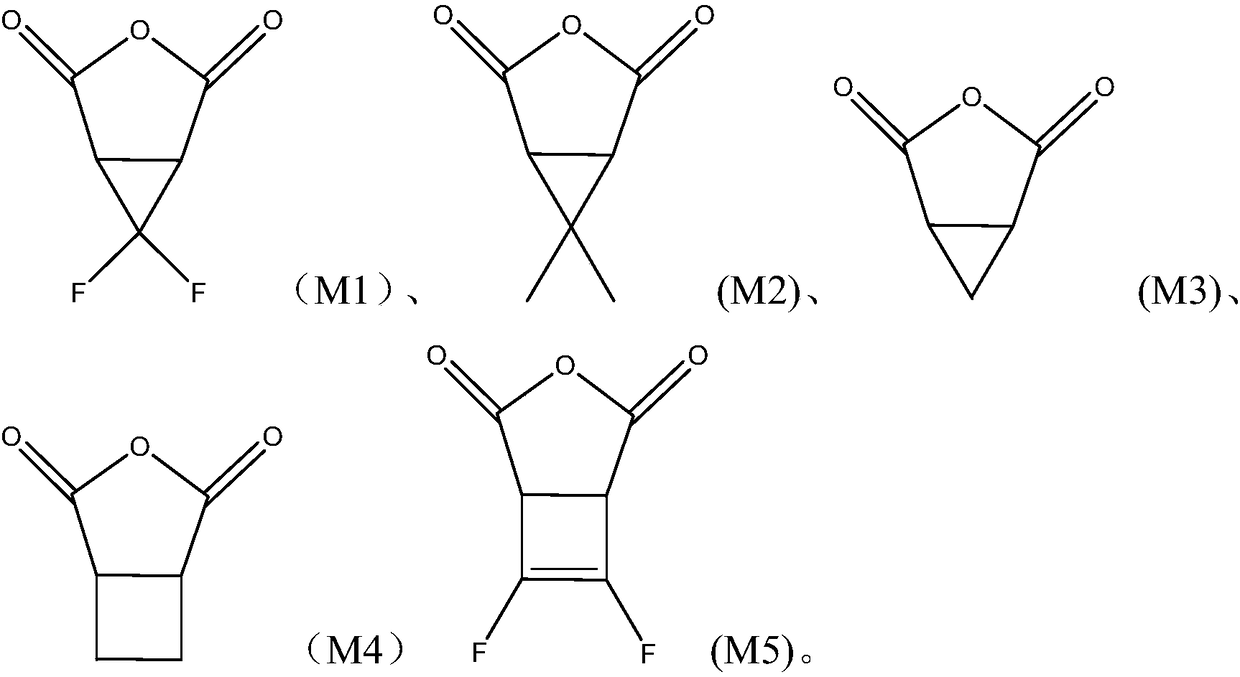

[0040] The preparation method of the electrolyte of Examples 2-40 and Comparative Examples 1-4 is similar to that of Example 1, that is, in a glove box (moisture content1 ~ M 5 The bridged anhydride additives correspond to the following compounds respectively:

[0041]

[0042] Preparation of lithium-ion batteries:

[0043] The preparation method of the lithium-ion battery of Examples 2-40 and Comparative Examples 1-4 is similar to the preparation method of the lithium-ion battery of Example 1. The positive active material and negative active material listed in Table 2 are used, and then injected into the lithium-ion battery of Example 2 respectively. ~40 and the electrolytic solution corresponding to Comparative Examples 1~4, and through processes such as encapsulation, shelving, chemical formation, aging, secondary encapsulation, and volume separation, the high-nickel ternary components...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com