Long-scale uniform thermal plasma arc generating method and device

A thermal plasma generation device technology, applied in the field of plasma physics and applied scientific research, can solve the problems of increasing equipment complexity, melting or gasification, and small arc column area, so as to improve feasibility and flexibility, increase Range and controllability, effects that reduce the difficulty of spawning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

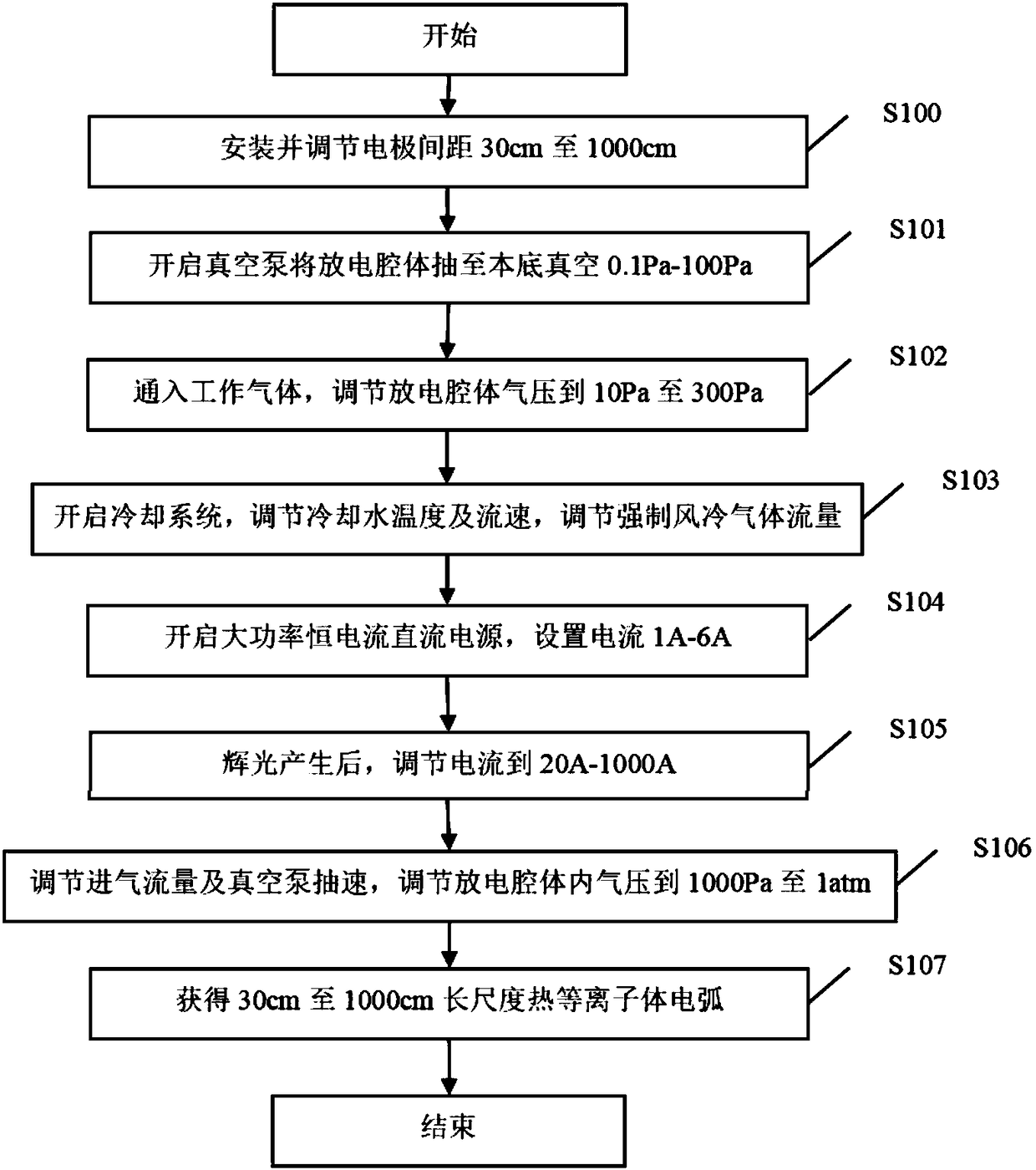

[0036] figure 1 A schematic flow chart of an embodiment of the long-scale uniform thermal plasma arc generation method provided by the present invention, such as figure 1 Shown:

[0037] In step S100, the cathode and the anode, the cathode holder and the anode holder are installed, and the distance between the cathode and the anode is adjusted to be 30 cm to 1000 cm.

[0038] In step S101, the vacuum pump is turned on, and the air pressure in the discharge chamber is evacuated to a background vacuum of 0.1 Pa to 100 Pa.

[0039] In step S102, the working gas is introduced to adjust the pressure in the discharge chamber to 10Pa to 300Pa.

[0040] In step S103, the cooling system is turned on, the cooling water temperature and flow rate are adjusted to effectively cool the cathode, anode, cathode seat, anode seat, and outer wall of the discharge chamber, and the flow rate of forced air-cooled gas is adjusted to cool the outer wall of the plasma generation chamber.

[0041] In...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com