Core-shell composite, method for producing same, electrode material, catalyst, electrode, secondary battery, and electric double-layer capacitor

A manufacturing method and complex technology, applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, battery electrodes, etc., can solve the problems of low electrode capacity, low energy density and low voltage of lithium-ion capacitors, and achieve high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0240] "Nanoporous Carbon"

[0241] In 20 mL of ethanol, 175 mg of zinc acetate and 300 mg of polyvinylpyrrolidone were dissolved to prepare an aqueous solution containing them. After adding zinc acetate and polyvinylpyrrolidone to water, the time for stirring their mixture was 30 minutes, and the temperature at the time of stirring the mixture was 25°C.

[0242] In 20 mL of ethanol, 263 mg of 2-methylimidazole was dissolved to prepare an ethanol solution containing 2-methylimidazole. After throwing 2-methylimidazole into ethanol, the time for stirring their mixture was 30 minutes, and the temperature at the time of stirring the mixture was 25°C.

[0243] The above-mentioned alcohol solution was added to the above-mentioned aqueous solution, and these solutions were stirred at 25° C. for 5 minutes. Thus, in the mixed solution of the above-mentioned aqueous solution and the above-mentioned alcohol solution, ZIF-8, which is a metal organic structure, was produced as a precipit...

Embodiment 2

[0267] "Button Battery"

[0268] As the organic electrolytic solution, 0.1 mL of tetraethylammonium tetrafluoroborate (TEA-BF4) of 1Mol / L was used, and for the current collector, an etched aluminum foil was used for the positive electrode and activated carbon (trade name : MSP-20), except that, in the same manner as in Example 1, the 2032-type button battery of Example 2 was produced. Here, in the negative electrode, activated carbon MSP-20, carbon black as a conductive material, and polyvinylidene fluoride (PVDF) as a binder were mixed with N-methyl-2-pyrrolidone at a ratio of 90:5:5wt%. A paste was obtained by mixing, and the obtained paste was coated on an etched aluminum foil using a doctor blade, and then dried at 160° C. to prepare a negative electrode material.

[0269] For the button cell of Example 2, using the VSP manufactured by Bio-Logic Corporation, at room temperature (23°C) and under the conditions of a scan rate of 1 mV / s to 200 mV / s, the voltage of 0 V to 2.5...

Embodiment 3

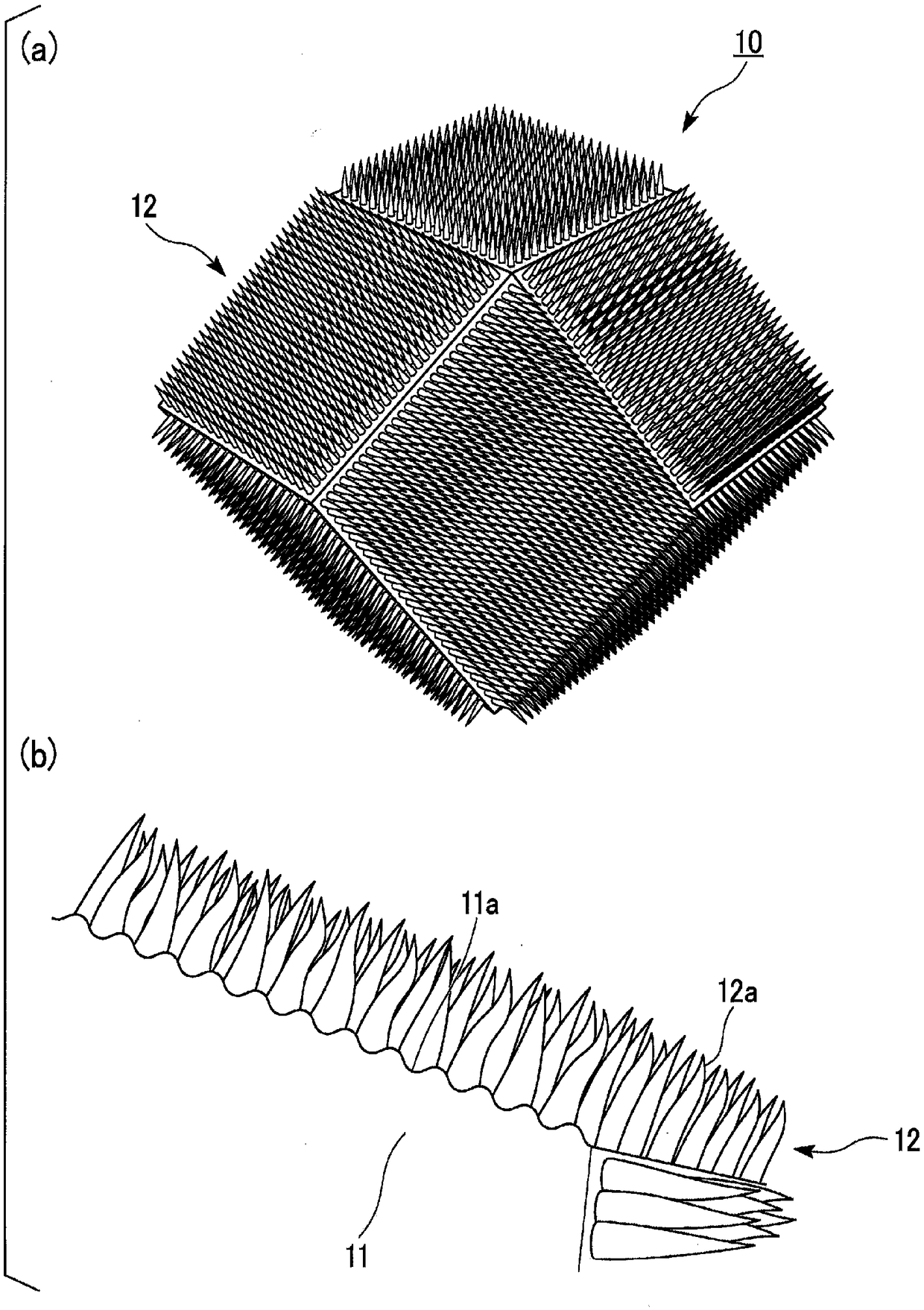

[0271] "Core-shell complex"

[0272] The nanoporous carbon obtained in Example 1 was impregnated for 10 minutes in an aqueous dispersion obtained by dispersing polythiophene-polystyrenesulfonic acid (PEDOT / PSS) in water.

[0273] Thereafter, the aqueous dispersion was filtered, the solid content contained in the aqueous dispersion was recovered, and the solid content was washed with distilled water.

[0274] Thereafter, the solid content was vacuum-dried at 80° C. for 24 hours to obtain nanoporous carbon and conductive polymer (PEDOT / PSS) nanorods extending outward from the pores on the surface of the nanoporous carbon. The core-shell complex of Example 3 of the shell layer.

[0275] "Button Battery"

[0276] A 2032-type coin cell of Example 3 was fabricated in the same manner as in Example 1 except that the core-shell composite of Example 3 was used.

[0277] For the button battery of Example 3, the capacity was obtained in the same manner as in Example 1. When the capaci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Average pore diameter | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com