PEDOT: PSS polymer, preparation method and application thereof

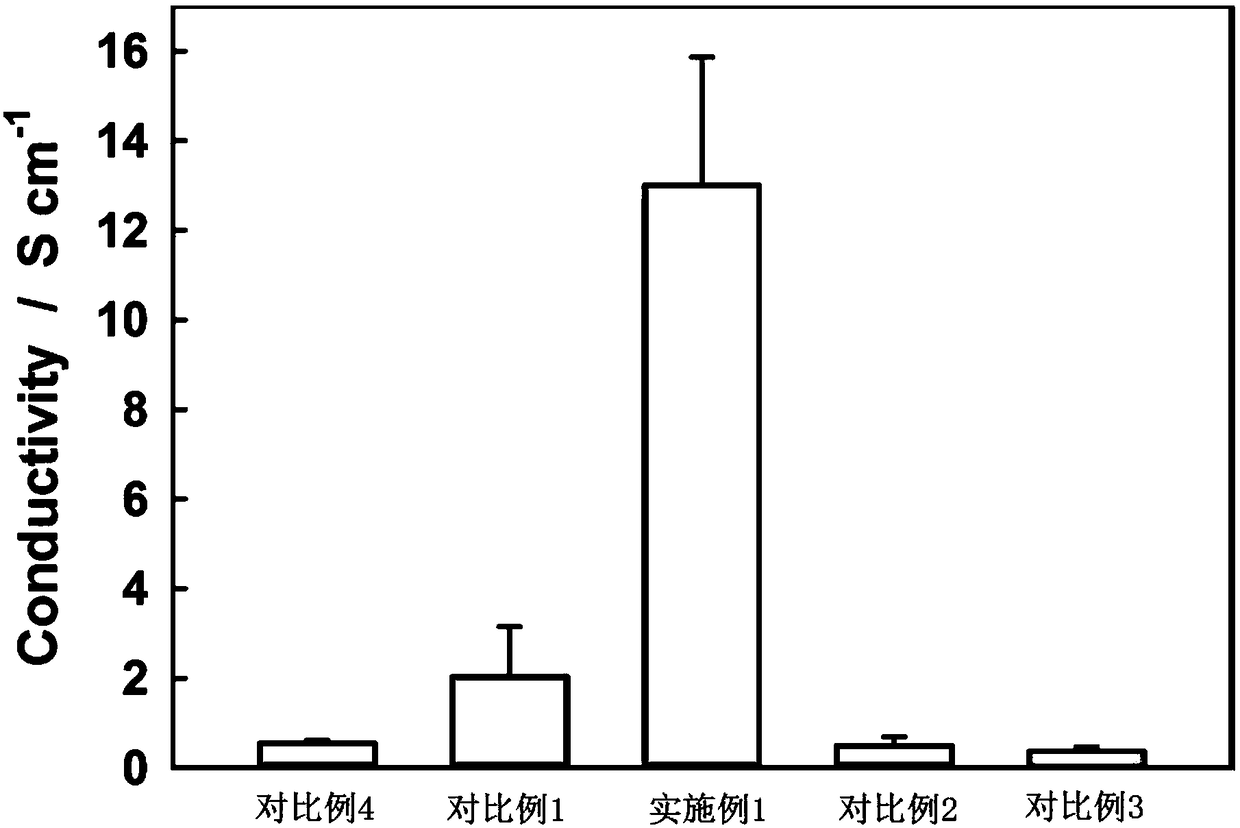

A technology of polymer and reaction solution, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems affecting applications and low film conductivity, and achieve easy operation, good dispersion, and good source-leakage current control performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

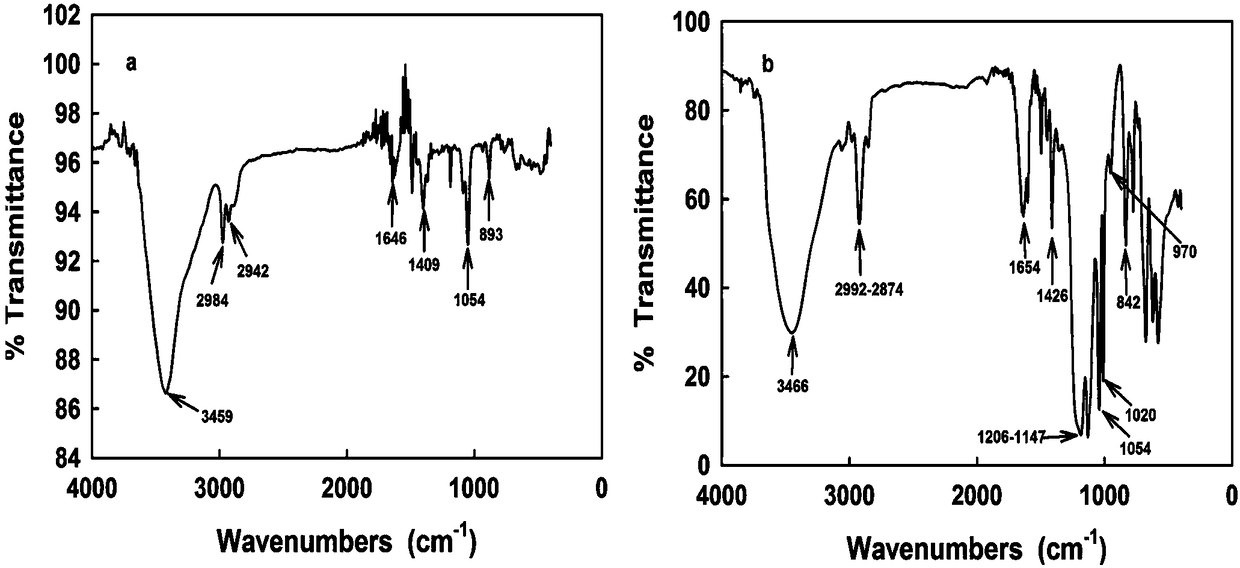

[0029] The present invention provides a PEDOT:PSS polymer of an embodiment, which is prepared by the following preparation method. The preparation method of the PEDOT:PSS polymer of an embodiment of the present invention comprises the following steps.

[0030] Step S100: Mixing the aqueous solution of polystyrene sulfonate and EDOT and adjusting the solution to acidity to obtain a mixed solution. Among them, the Chinese name of EDOT is 3,4-ethylenedioxythiophene.

[0031] The mass volume ratio of polystyrene sulfonate and EDOT will affect the degree of polymerization of EDOT polymerization and the ratio of PEDOT (poly 3,4-ethylenedioxythiophene) and polystyrene sulfonate in PEDOT:PSS polymer, and then It affects the conductivity and dispersion properties of PEDOT:PSS polymers in water.

[0032] Preferably, the mass percentage of the polystyrene sulfonate in the polystyrene sulfonate aqueous solution is 1%-5%. Preferably, the mass volume ratio of polystyrene sulfonate to EDO...

Embodiment 1

[0054] 25 μL of light yellow oily EDOT was added to 3.1 mL of 2 wt.% NaPSS solution (the mass of NaPSS was 62.5 mg), followed by dropwise addition of concentrated hydrochloric acid to adjust the pH of the solution to 1 to obtain a mixed solution. The reaction vessel was sealed and evacuated and protected by argon, and 4 mL of FeCl was added with a syringe at an even speed under the condition of ultrasonic treatment at a frequency of 40KHz. 3 and an aqueous solution of potassium persulfate, in which FeCl 3 and K 2 S 2 o 8 The concentrations were 12.9mmoL / L and 52.5mmoL / L respectively, and continued to sonicate for 5min. Then transfer the reaction vessel to a water bath with a water bath temperature of 10°C, stir and react at a speed of 800 rpm for 24 hours, filter the reacted reaction liquid with suction to obtain a solid, wash with hexane to remove unreacted EDOT, and then use a large amount of Wash with ethanol, and then dry in a constant temperature drying oven at 50°C t...

Embodiment 2

[0056] 62.5 μL of light yellow oily EDOT was added to 3.1 mL of 2 wt.% NaPSS solution, and then concentrated hydrochloric acid was added dropwise to adjust the pH of the solution to 2 to obtain a mixed solution. The reaction vessel was sealed and evacuated and protected by argon, and 3.1mL FeCl was added with a syringe at an even speed under the condition of ultrasonic treatment at a frequency of 30KHz. 3 and an aqueous solution of potassium persulfate, in which FeCl 3 and K 2 S 2 o 8 The concentrations were 12.9mmoL / L and 25.8mmoL / L respectively, and continued to sonicate for 8min. Then the reaction vessel was transferred to a water bath with a water bath temperature of 30°C, stirred and reacted at a speed of 800 rpm for 15 h, and the solid was obtained by suction filtration, washed with hexane to remove unreacted EDOT, then washed with a large amount of ethanol, and then heated at 60 °C in a constant temperature drying oven to obtain a dark blue solid PEDOT:PSS polymer. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com