Alloy coating resistant to high temperature oxidation and sulfur and chlorine corrosion and preparation method thereof

A technology of high temperature oxidation resistance and alloy coating, which is applied in the direction of metal material coating process, coating, molten spraying, etc., can solve the problem of large difference in thermal expansion coefficient, unfavorable combination, and difficulty in achieving satisfactory high temperature oxidation resistance and corrosion resistance and other problems, to achieve the effect of increasing the density, improving the bonding performance, and improving the anti-coking performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] (1) The substrate is a superalloy. Pretreatment of the surface of the metal substrate to be sprayed: sandblasting, ultrasonic cleaning, compressed air drying.

[0053] (2) The CoNiMoCrAlSiY alloy powder is deposited on the surface of the metal substrate by atmospheric plasma process. The composition of the alloy powder is Ni: 25wt%, Mo: 10wt%, Cr: 15wt%, Al: 6wt%, Si: 2wt%, Y: 0.5wt%, Co: balance. Spraying parameters are: argon flow rate 40slpm, hydrogen flow rate 9slpm, current 600A, power 45kW, powder delivery carrier gas flow rate 3.0slpm, powder delivery rate 35g / min, spraying distance 120mm.

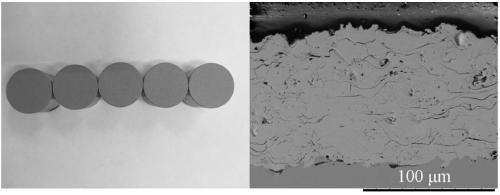

[0054] figure 1 The digital photos and cross-sectional SEM images of the obtained samples show that the thickness of the coating is about 110 μm, and the coating is tightly combined with the substrate. The bond strength test was carried out on the sample, and the test value was 61.2±1.5MPa. The thermal conductivity of the coating is 19.4W / (m K) (600°C), indicating that th...

Embodiment 2

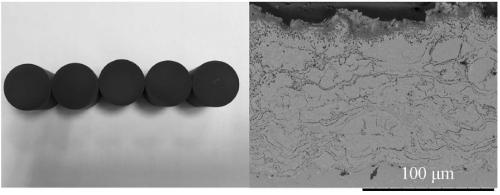

[0056] The preparation method is the same as in Example 1, and the resulting sample is thermally shocked 50 times (900° C. to room temperature). figure 2 Digital photos and cross-sectional SEM images of coating samples after thermal shock. After thermal shock, the coating is intact without cracks or peeling off. The bond strength test was carried out on the sample after thermal shock, and the test value was 52.9±4.2MPa.

Embodiment 3

[0058] (1) The base material is the solid part of the rising pipe used in the raw gas sensible heat recovery project.

[0059] (2) The CoNiMoCrAlSiY alloy powder is deposited on the inner wall of the riser pipe for the sensible heat recovery project of the treated crude gas by using the atmospheric plasma process. The composition of the alloy powder is Ni: 25wt%, Mo: 10wt%, Cr: 15wt%, Al: 6wt%, Si: 2wt%, Y: 0.5wt%, Co: balance. Spraying parameters are: argon flow rate 35 slpm, hydrogen flow rate 5 slpm, current 400A, power 32kW, powder delivery carrier gas flow rate 3.0 slpm, powder delivery rate 35g / min.

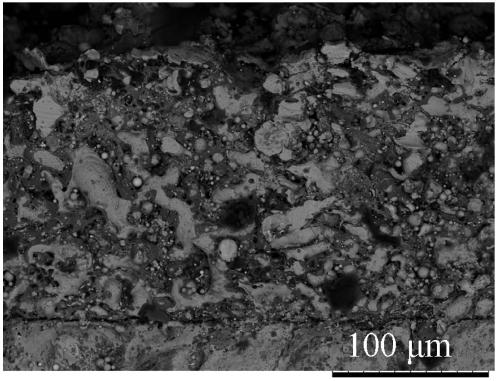

[0060] (3) Service the riser with inner wall coating for 1 year under the actual working condition. An anatomical analysis of the riser was carried out after service, and the SEM image of the section of the coating sample intercepted is as follows: image 3 shown. After service, the coating is intact and still tightly bonded to the substrate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com