Slow-release drinking water disinfectant and preparation method thereof

A disinfectant and slow-release technology, applied in the field of slow-release drinking water disinfectant and its preparation, can solve the problems of high content and low potassium hydrogen persulfate content, and achieve the effects of long storage time, long action time and strong toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

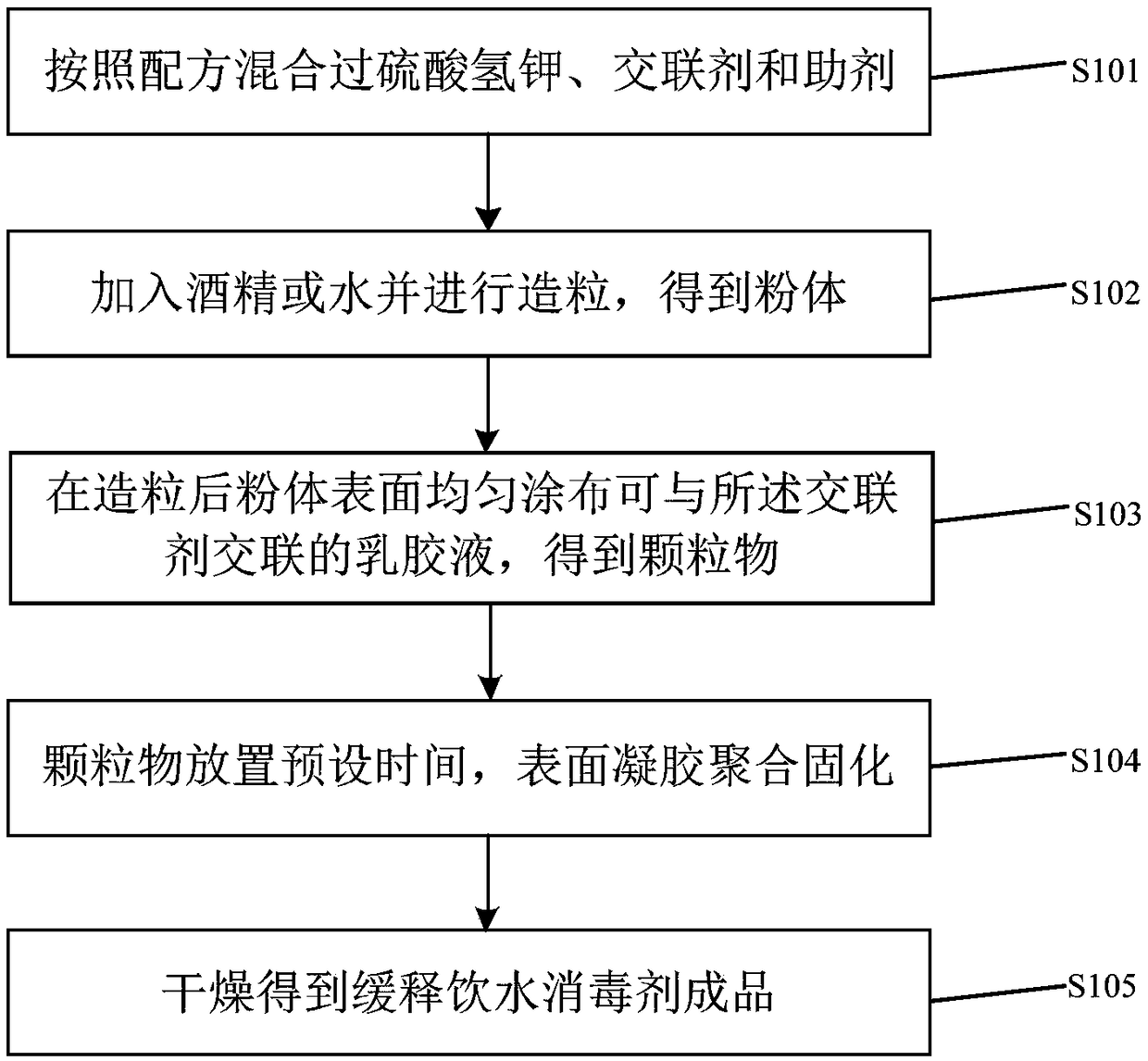

[0040] The present invention provides a kind of preparation method of slow-release drinking water disinfectant, comprising:

[0041] S101: mixing potassium hydrogen persulfate, crosslinking agent and auxiliary agent according to the formula to obtain a mixture;

[0042] Wherein, the formula includes 70-90 parts of potassium hydrogen persulfate in parts by weight; 6-13 parts of auxiliary agent; 2-5 parts of crosslinking agent;

[0043] Wherein, auxiliary agent comprises anionic surfactant and filler;

[0044] The anionic surfactant is selected from one or a combination of alkyl sodium sulfate, sodium dodecylbenzenesulfonate, sodium alkylsulfonate, and oleoyl amino acid sodium; the anionic surfactant can reduce the surface tension of water and contribute to The disinfectant is evenly dispersed in the water to be disinfected to improve the disinfection effect. Preferably, the anionic surfactant is selected sodium dodecylbenzene sulfonate, and its addition weight part is 1-3 par...

Embodiment 1

[0067] formula:

[0068] 90 parts of potassium hydrogen persulfate, 5 parts of crosslinking agent, 2 parts of anionic surfactant, 5 parts of filler agent; 5 parts of emulsion;

[0069] Wherein, the cross-linking agent is selected from borax, the anionic surfactant is selected from sodium dodecylbenzenesulfonate, the filler is selected from sodium chloride; the latex solution is selected from polyvinyl alcohol solution with a concentration of 2%.

[0070] Preparation:

[0071] (1) Potassium hydrogen persulfate, crosslinking agent, filler, anionic surfactant are fully mixed;

[0072] (2) Add 20% alcohol of the mixture mass (the volume ratio of water to alcohol is 2:1), and carry out rotary granulation;

[0073] (3) Spray the latex in the turntable granulator, and turn the turntable to mix;

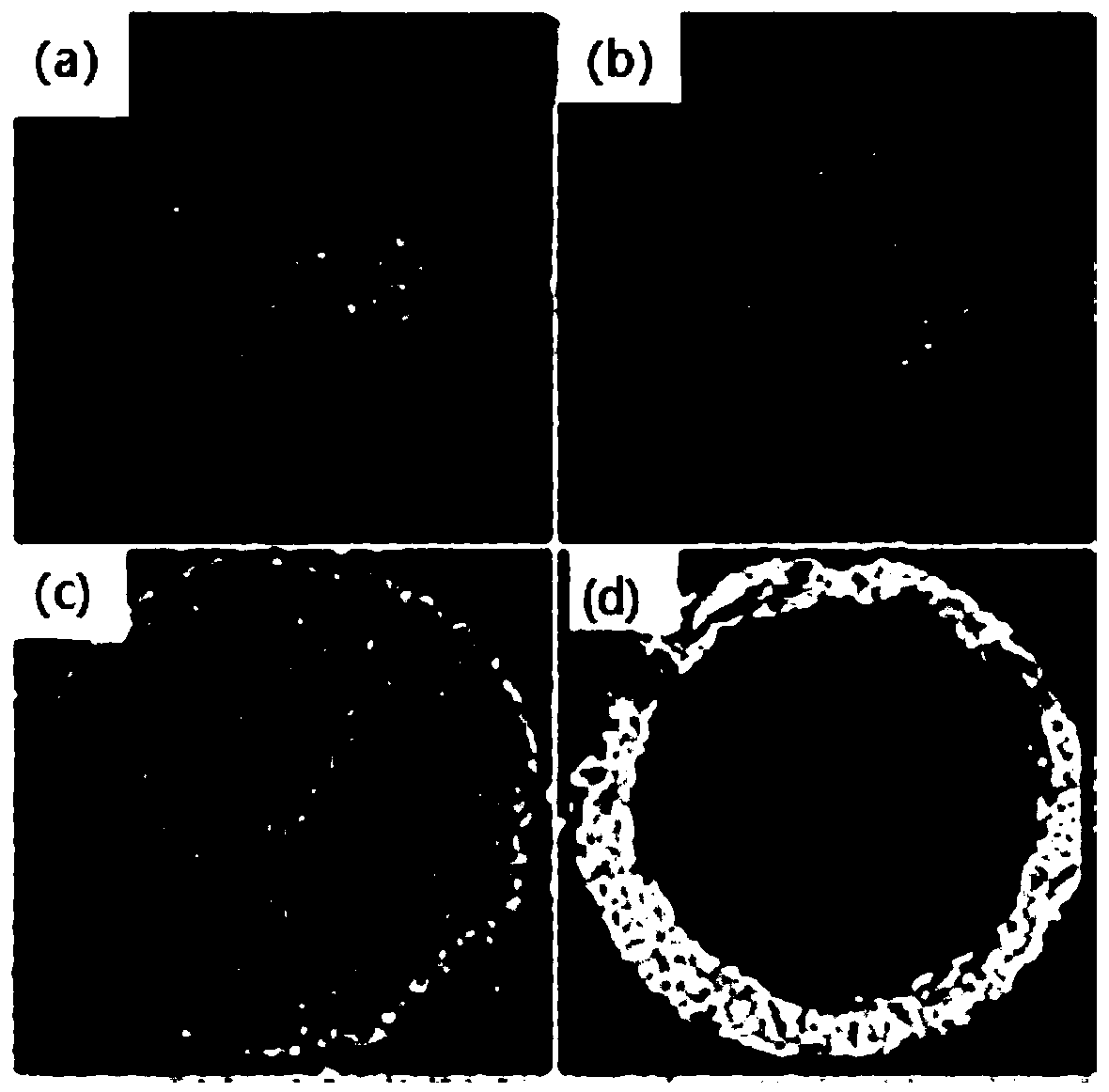

[0074] (4) The obtained material is placed in the air for 1.5h to make the surface gel solidify;

[0075] (5) Use a belt-type tunnel kiln dryer to dry at 80° C., stop drying after drying...

Embodiment 2

[0077] formula:

[0078] 80 parts of potassium hydrogen persulfate, 3 parts of crosslinking agent, 3 parts of anionic surfactant, 10 parts of filler; 4 parts of emulsion;

[0079] Among them, the cross-linking agent is selected glutaraldehyde, the anionic surfactant is selected sodium dodecylbenzenesulfonate, and the filler is selected sodium chloride; the latex liquid is selected from a chitosan solution with a concentration of 2%, and the chitosan is dissolved in acetic acid .

[0080] Preparation:

[0081] (1) Potassium hydrogen persulfate, crosslinking agent, filler, anionic surfactant are fully mixed;

[0082] (2) Add 25% alcohol (volume ratio of water to alcohol is 2:1) of the mixture mass, and carry out rotary granulation;

[0083] (3) Spray the latex in the turntable granulator, and turn the turntable to mix;

[0084] (4) The obtained material is placed in the air for 2 hours to make the surface gel solidify;

[0085] (5) Use a belt-type tunnel kiln dryer to dry a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com