Welding deviation detection system and detection method based on GMAW molten pool contour features

A technology of deviation detection and contour features, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve problems such as welding deviation, achieve the effect of improving quality, image acquisition quality, and signal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

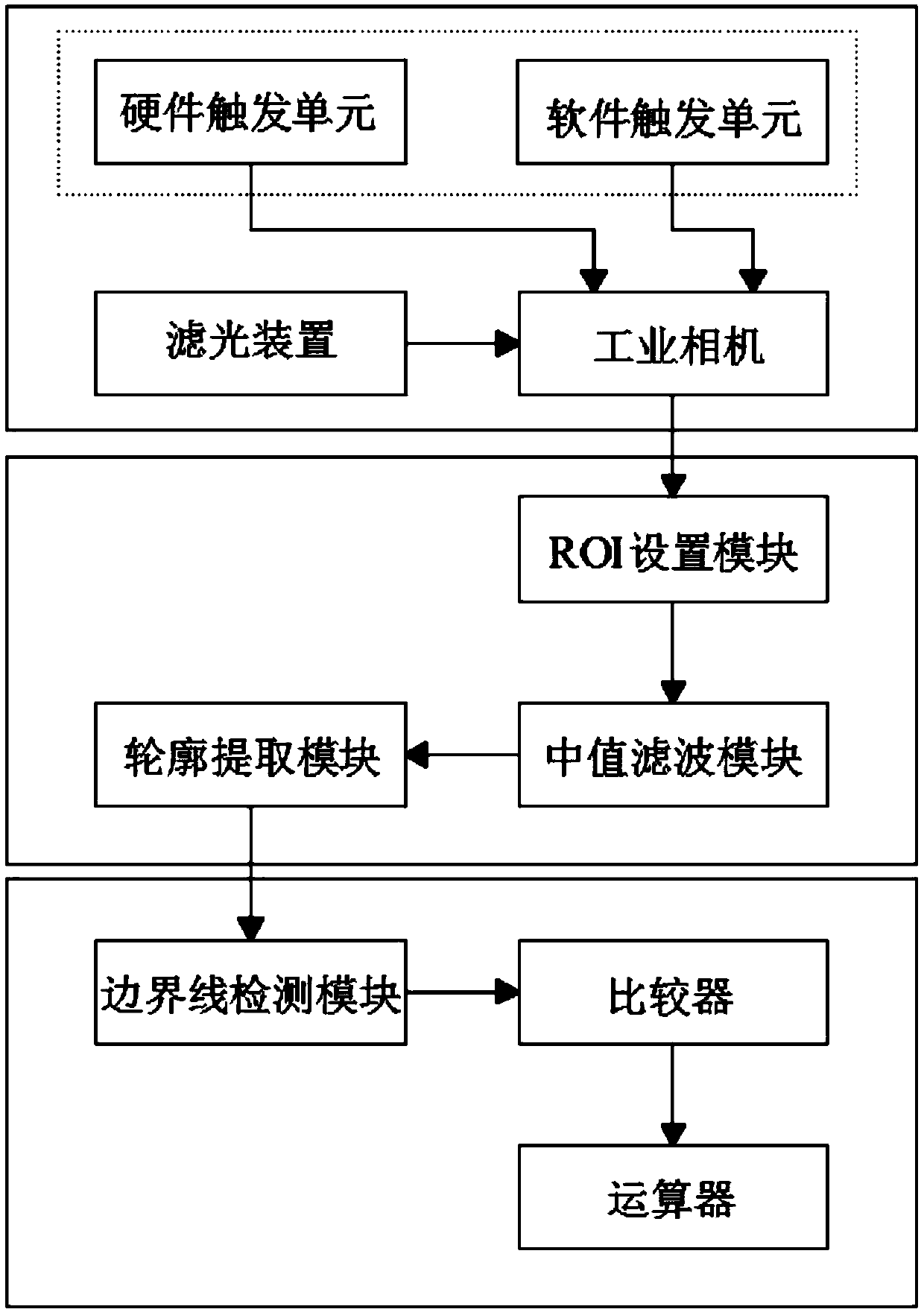

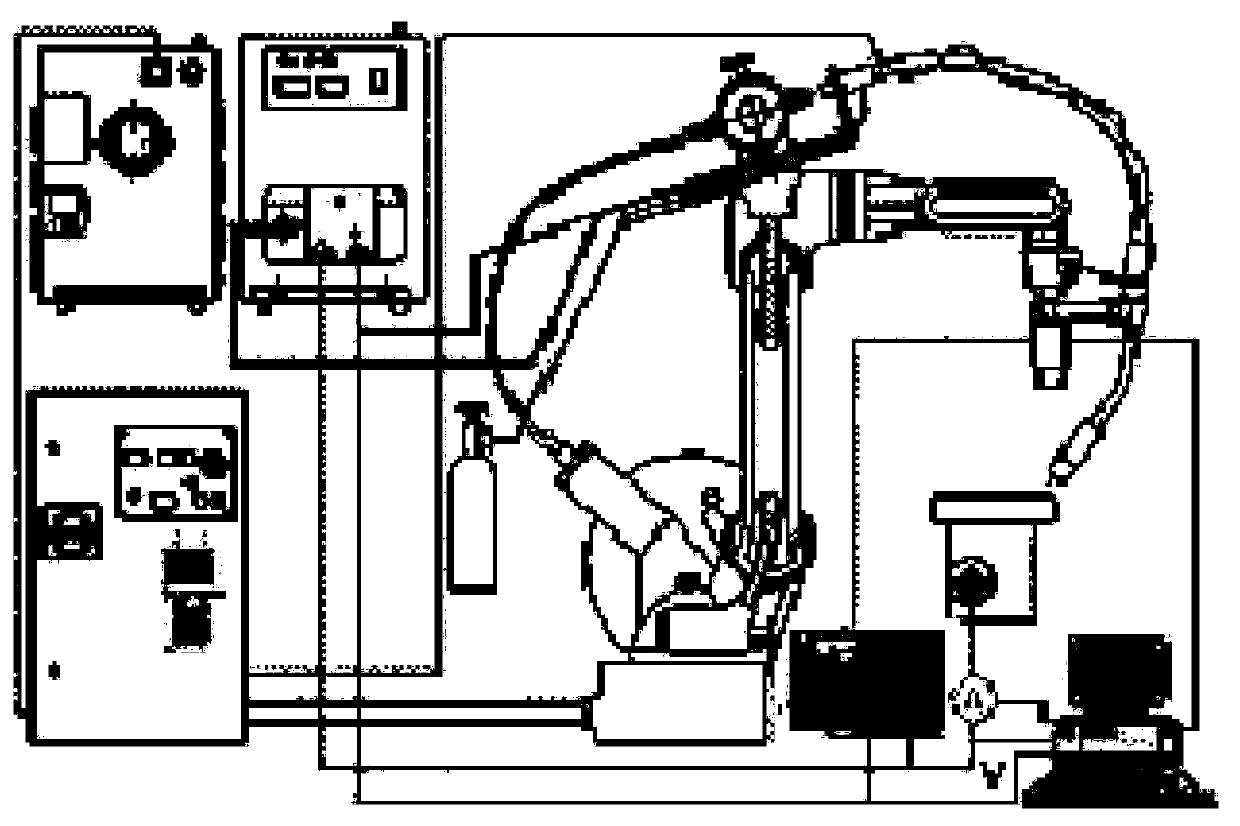

[0050] see figure 1 as well as figure 2 In this embodiment, the I-groove welding deviation detection system based on GMAW (gas metal arc welding) molten pool profile features includes an optical system, an image processing system, and an image analysis system. In this embodiment, the welding deviation detection system is applied to an arc welding robot system, which includes a MOTOMAN-UP6 robot and a welding power supply MOTOWELD-S350. Among them, this embodiment is tested, using the GMAW welding method, the joint form is butt joint, and it is an I-shaped groove, the base material is Q235, the plate size is 180mmx50mmx5mm, and the pretreatment method is sandpaper grinding to remove rust. The welding process parameters are shown in Table 1.

[0051] Table 1 Welding process parameter list

[0052]

[0053] The optical system includes a camera trigger module, an industrial camera 3, and a filter device.

[0054] see image 3 , the industrial camera 3 is used to take imag...

Embodiment 2

[0086] This embodiment discloses a welding deviation detection method based on GMAW molten pool contour features, which is applied to the welding deviation detection system based on GMAW molten pool contour features in Embodiment 1.

[0087] The welding deviation detection method includes the following steps.

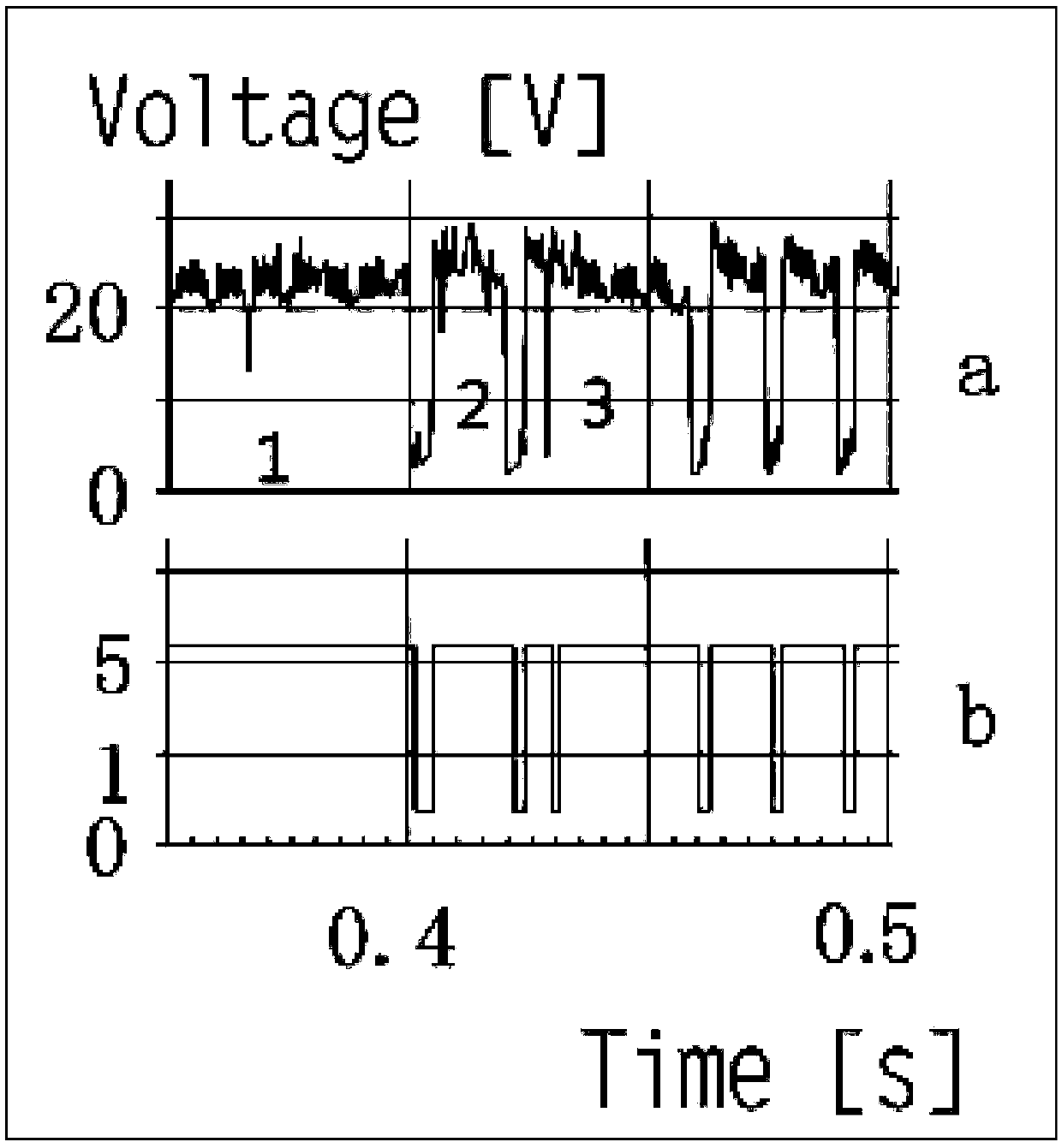

[0088] (1) Detecting the arc voltage during welding, and triggering a trigger signal 1 when the arc voltage is lower than a preset voltage value, and triggering a trigger signal 2 when the arc voltage is higher than the preset voltage value, The trigger signal 1 and the trigger signal 2 are combined into a camera trigger signal in time sequence and transmitted to the industrial camera, so that the industrial camera triggers the industrial camera to take pictures of the melt pool image during short-circuit transition when the camera trigger signal is on a falling edge .

[0089] (2) Segment the molten pool image into two ROIs that respectively display a groove profile a...

Embodiment 3

[0097]The welding deviation detection system based on the contour features of the GMAW molten pool in this embodiment adds an alarm device on the basis of Embodiment 1, and a controller is added to the image analysis system. The controller controls the alarm device to send out an alarm signal for welding torch 2 to the right when the pixel deviation Δ is less than zero, and to send an alarm signal for welding torch 2 to the left when the pixel deviation Δ is greater than zero. Therefore, in this embodiment, an alarm device is provided to judge whether the welding torch 2 is left or right according to the pixel deviation Δ, and a corresponding alarm signal is sent, so that the operator can make corresponding processing in time, and improve welding efficiency and welding quality.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com