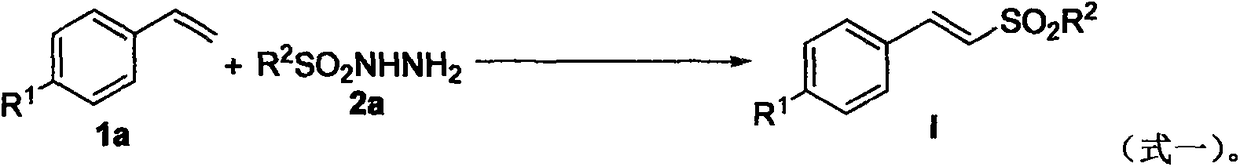

Green preparation method for vinyl sulfone derivative in aqueous phase

A technology of vinyl sulfone and derivatives, which is applied in the field of synthesis of vinyl sulfone derivatives to achieve a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

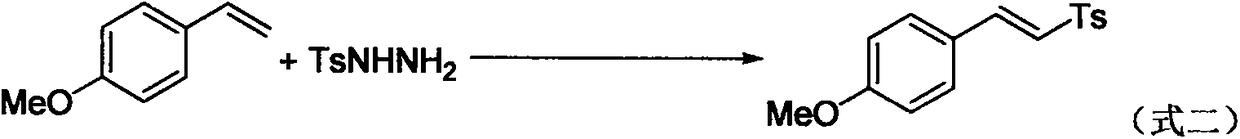

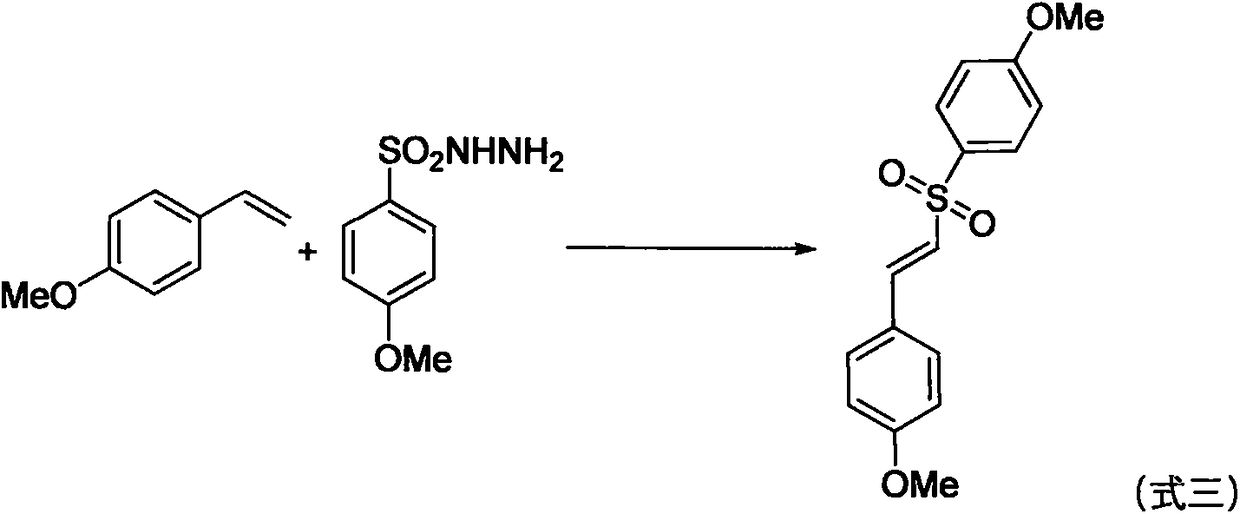

[0028] The synthesis of embodiment 1 compound (E)-1-methoxy group-4-(2-tosyl vinyl) benzene

[0029]

[0030] Add 4-methoxy-styrene ( 40.2mg, 0.3mmol), p-toluenesulfonyl hydrazide (67.0mg, 0.36mmol), TBAI (tetrabutylammonium iodide, 22.1mg, 0.06mmol), TBHP (tert-butanol peroxide, 32.4mg, 0.36 mmol) and solvent water (1mL), the reaction bottle was placed at 25°C under air atmosphere conditions to stir the reaction, and the reaction process was monitored by TLC or GC until the raw materials were completely reacted (reaction time 36 hours), and the reaction solution after the reaction was completed Extracted three times with ethyl acetate, the organic phase was dried over anhydrous sodium sulfate, filtered and concentrated under reduced pressure to remove the solvent, and the residue was separated by column chromatography (elution solvent: ethyl acetate / n-hexane) to obtain the target product (E )-1-methoxy-4-(2-tosylvinyl)benzene. (80% yield); 1H NMR (400MHz, DMSO-d6) δ: 7...

Embodiment 2

[0032] No accelerator TBAI is added, all the other conditions are the same as in Example 1, the yield of target product (E)-1-methoxyl-4-(2-tosylvinyl)benzene is 0%, 4-methoxyl- Styrene recovery was 77%.

Embodiment 3

[0034] Substitute iodine simple substance for TBAI in embodiment 1, all the other conditions are the same as embodiment 1, through TLC or GC monitoring reaction process, to raw material reaction completely (reaction time 36 hours), the reaction solution after the reaction is completed is extracted three times with ethyl acetate , the organic phase was dried with anhydrous sodium sulfate, filtered and concentrated under reduced pressure to remove the solvent, and the residue was separated by column chromatography (elution solvent: ethyl acetate / n-hexane) to obtain the target product (E)-1-methoxy The yield of 4-(2-tosylvinyl)benzene was 44%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com