Catalytic charing high efficiency halogen-free flame retardant PC (Polycarbonate)/ABS (Acrylonitrile Butadiene Styrene) mixture and preparation method thereof

A mixture and high-efficiency technology, which is applied in the field of catalytic charcoal formation, high-efficiency halogen-free flame-retardant PC/ABS mixture and its preparation, can solve problems such as difficult to overcome the ignition effect of candle wicks, and achieve good compatibility and dispersion, and the addition amount Small, the effect of improving the flame retardant performance of the matrix

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

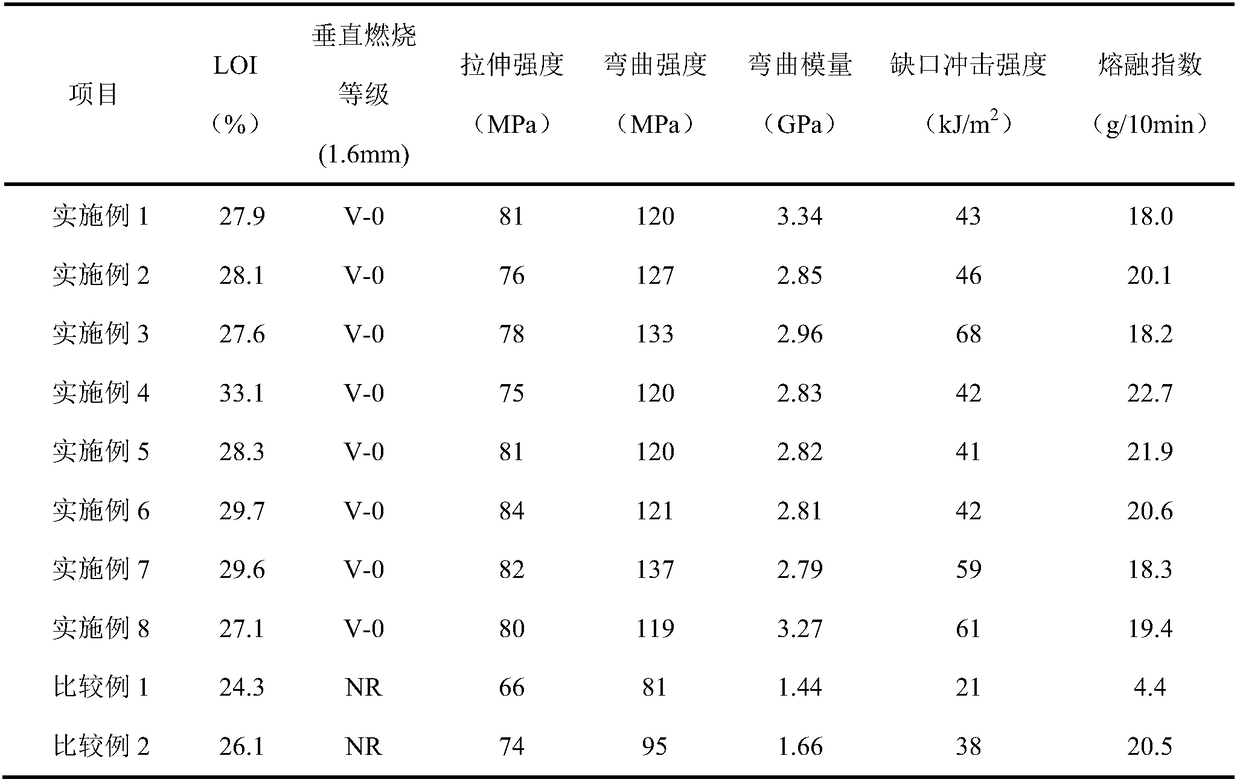

Embodiment 1

[0053] The catalyzed charcoal-forming halogen-free flame-retardant carbon fiber reinforced PC / ABS mixture of the present embodiment is mainly made of the following raw materials in weight percentage: PC resin (59%), ABS resin (14.7%), chopped carbon fiber (15%), EMA (5%), RDP (5%), phenoxyphosphazene (0.5%), zirconium phosphate modified triazine silicon-containing char former (0.5%), NOR116 (0.3%).

[0054] Mix PC, ABS, EMA, RDP, NOR116, phenoxyphosphazene and zirconium phosphate-modified triazine silicon-containing carbon formers at high speed for 20 minutes and then put them into the main feeding bin of the twin-screw extruder. The main feeding screw speed 25rpm, the chopped carbon fiber is placed in the side feeding bin of the twin-screw extruder. The control temperature (eight sections from the feeding port to the nozzle outlet) is 200°C, 220°C, 220°C, 230°C, 235°C, 245°C, 245°C, 250°C, and the vacuum pressure of the barrel in the twin-screw extrusion process should be Co...

Embodiment 2

[0056] The catalyzed charcoal-forming halogen-free flame-retardant carbon fiber reinforced PC / ABS mixture of the present embodiment is mainly made of the following raw materials in weight percentage: PC resin (67%), ABS resin (16.7%), chopped carbon fiber (5%), EMA (5%), RDP (5%), phenoxyphosphazene (0.5%), zirconium phosphate modified triazine silicon-containing char former (0.5%), NOR116 (0.3%).

[0057] Mix PC, ABS, EMA, RDP, NOR116, phenoxyphosphazene and zirconium phosphate-modified triazine silicon-containing carbon formers at high speed for 20 minutes and then put them into the main feeding bin of the twin-screw extruder. The main feeding screw speed 25rpm, the chopped carbon fiber is placed in the side feeding bin of the twin-screw extruder. The control temperature (eight sections from the feeding port to the nozzle outlet) is 200°C, 220°C, 220°C, 230°C, 235°C, 245°C, 245°C, 250°C, and the vacuum pressure of the barrel in the twin-screw extrusion process should be Con...

Embodiment 3

[0059] The catalyzed charcoal-forming halogen-free flame-retardant carbon fiber reinforced PC / ABS mixture of the present embodiment is mainly made of the following raw materials in weight percent: PC resin (37%), ABS resin (37%), chopped carbon fiber (15%), EMA (5%), RDP (5%), phenoxyphosphazene (0.5%), zirconium phosphate modified triazine silicon-containing char former (0.5%), NOR116 (0.3%).

[0060] Mix PC, ABS, EMA, RDP, NOR116, phenoxyphosphazene and zirconium phosphate-modified triazine silicon-containing carbon formers at high speed for 20 minutes and then put them into the main feeding bin of the twin-screw extruder. The main feeding screw speed 25rpm, the chopped carbon fiber is placed in the side feeding bin of the twin-screw extruder. The control temperature (eight sections from the feeding port to the nozzle outlet) is 200°C, 220°C, 220°C, 230°C, 235°C, 245°C, 245°C, 250°C, and the vacuum pressure of the barrel in the twin-screw extrusion process should be Control...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com