Special anti-pilling finishing liquid for dacron fabric

A polyester fabric, anti-pilling technology, used in fiber processing, textiles and papermaking, improved hand-feeling fibers, etc., can solve the problems of poor appearance and hand-feeling of fabrics, reduced elastic recovery ability of polyester fabrics, and impact on wearability. The effect of improving anti-pilling performance, improving anti-pilling performance and good softening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

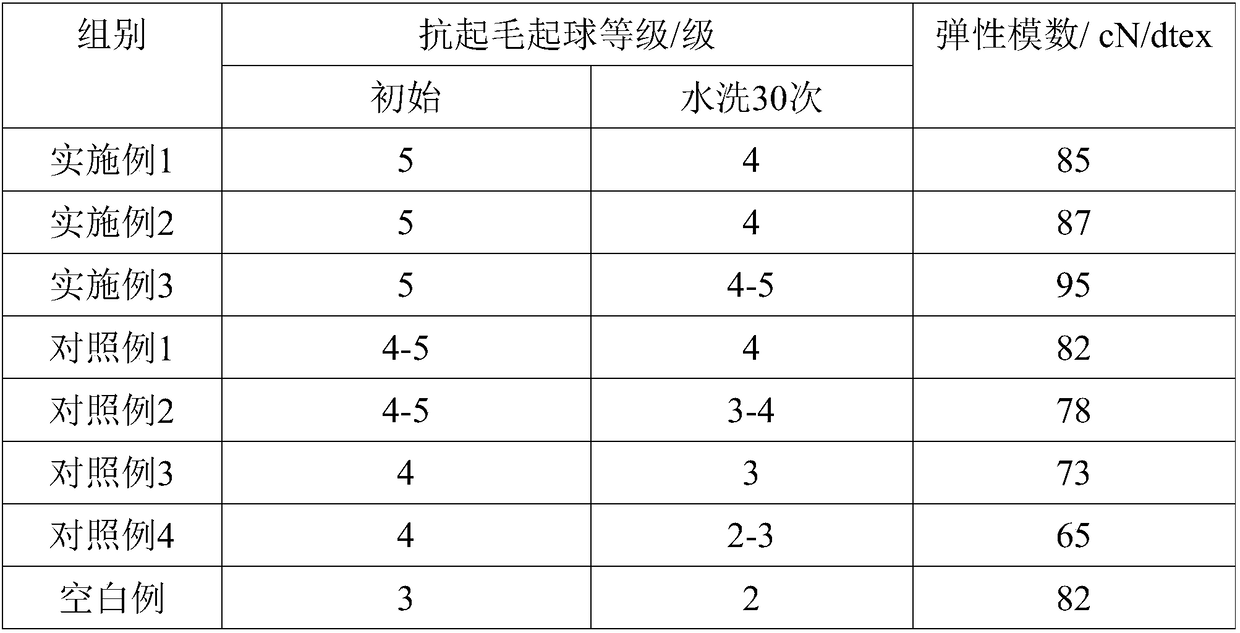

Examples

Embodiment 1

[0022] Preparation of anti-pilling finishing solution: 20g methacryloxyethyltrimethylammonium chloride, 10g N-methylolacrylamide, 5g hydroxyl-terminated polydimethylsiloxane, 3g cocoyl glycine Sodium, 2g water treatment grade polyglutamic acid, 1g propylene glycol alginate, 0.5g polyethylene glycol 6000, 0.5g sodium pyrrolidone carboxylate, 0.5g cationic polyacrylamide, 0.5g potassium persulfate, 200g water.

[0023] Preparation of hydroxyl-terminated polydimethylsiloxane: Mix 100g of hydroxyl silicone oil, 100g of methylphenyl cyclosiloxane, and 3g of tetramethylammonium hydroxide silicon alkoxide, heat to 70°C and keep stirring for 30min, then continue Heat to 110°C and keep stirring for 6 hours, then continue heating to 170°C and keep stirring for 30 minutes, and finally remove low boilers at 180°C and 1333Pa to obtain hydroxyl-terminated polydimethylsiloxane. Wherein, the hydroxyl mass fraction of the hydroxyl silicone oil is 8%, and the tetramethylammonium hydroxide mass ...

Embodiment 2

[0025] Preparation of anti-pilling finishing solution: 25g methacryloxyethyltrimethylammonium chloride, 10g N-methylolacrylamide, 5g hydroxyl-terminated polydimethylsiloxane, 2g cocoyl glycine Sodium, 2g water treatment grade polyglutamic acid, 2g propylene glycol alginate, 0.5g polyethylene glycol 6000, 0.5g sodium pyrrolidone carboxylate, 0.5g cationic polyacrylamide, 0.5g potassium persulfate, 200g water.

[0026] Preparation of hydroxyl-terminated polydimethylsiloxane: Mix 100g of hydroxyl silicone oil, 100g of methylphenyl cyclosiloxane, and 3g of tetramethylammonium hydroxide silicon alkoxide, heat to 70°C and keep stirring for 30min, then continue Heat to 110°C and keep stirring for 6 hours, then continue heating to 170°C and keep stirring for 30 minutes, and finally remove low boilers at 180°C and 1333Pa to obtain hydroxyl-terminated polydimethylsiloxane. Wherein, the hydroxyl mass fraction of the hydroxyl silicone oil is 8%, and the tetramethylammonium hydroxide mass ...

Embodiment 3

[0028] Preparation of anti-pilling finishing solution: 25g methacryloxyethyltrimethylammonium chloride, 10g N-methylolacrylamide, 5g hydroxyl-terminated polydimethylsiloxane, 2g cocoyl glycine Sodium, 2g water treatment grade polyglutamic acid, 2g propylene glycol alginate, 0.5g polyethylene glycol 6000, 0.5g sodium pyrrolidone carboxylate, 0.5g cationic polyacrylamide, 0.5g potassium persulfate, 200g water.

[0029] Preparation of hydroxyl-terminated polydimethylsiloxane: Mix 100g of hydroxyl silicone oil, 100g of methylphenyl cyclosiloxane, and 3g of tetramethylammonium hydroxide silicon alkoxide, heat to 70°C and keep stirring for 30min, then continue Heat to 110°C and keep stirring for 6 hours, then continue heating to 170°C and keep stirring for 30 minutes, and finally remove low boilers at 180°C and 1333Pa to obtain hydroxyl-terminated polydimethylsiloxane. Wherein, the hydroxyl mass fraction of the hydroxyl silicone oil is 8%, and the tetramethylammonium hydroxide mass ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com