Device for detecting halogen elements in ore products by water vapor distillation method and detection method

A steam distillation method and a technology for mineral products, which are applied in the field of halogen element devices, can solve the problems of affecting the absorption effect of the absorbing liquid, reducing the work efficiency, and failing to achieve a complete reaction, so as to improve the experimental recovery rate and the experimental success rate, The effect of reducing the probability of equipment errors and preventing acid vapor and acid reflux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

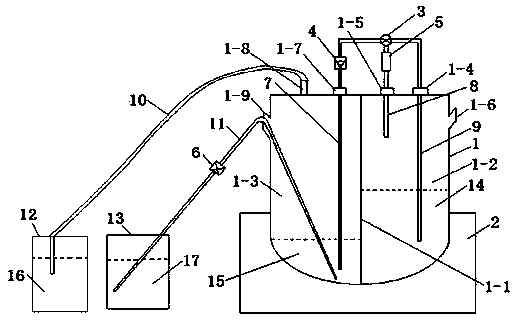

[0029] Such as figure 1 As shown, a device for detecting halogen elements in mineral products by steam distillation, including a hemispherical double-chamber retort 1, an electric heating jacket 2, a three-way valve 3, a gas-liquid one-way valve 4, and a rotameter 5 , spring clip 6, quartz tube 7, short quartz tube 8, long quartz tube 9, condenser tube 10, waste liquid tube 11, absorption bottle 12, waste liquid bucket 13, distilled water 14, sulfur-phosphorus mixed acid 15, absorption liquid 16, waste liquid17.

[0030] A partition 1-1 is arranged in the hemispherical double-chamber retort 1, and one side of the partition 1-1 is a water distillation chamber 1-2, and the other side of the partition 1-1 is a chemical reaction chamber 1-3. There are standard port I1-4 and standard port II1-5 on the top of the chamber 1-2, a water inlet 1-6 is provided on the side of the upper end of the water distillation chamber 1-2, and a standard port is provided on the top of the chemical r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com