Preparation method and application of Pd/C3N4@biomass carbon fiber composite film

A C3N4, fiber composite technology, applied in organic compound/hydride/coordination complex catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problem of catalytic performance and degradation efficiency decline, catalytic membrane porosity specific surface area Small, organic polymer membrane incompatibility and other problems, to achieve the effect of improving photocatalytic performance, improving photocatalytic efficiency, and large membrane pore size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Pd / C 3 N 4 @Preparation of biomass carbon fiber composite photocatalyst

[0029] Weigh 2g cattail, wash and dry, soak in saturated urea solution, transfer to a tube furnace after drying, and calcinate at 550°C for 2h under the protection of nitrogen, with a heating rate of 2.3°C / min, take it out after natural cooling to obtain C 3 N 4 @CF, to be used;

[0030] Take 1g C 3 N 4 @CF composite photocatalyst is dispersed in 100ml water for use, take 0.01g PdCl 2 Dissolve in 10ml of water and add to the above dispersion liquid and stir for 2h, then dissolve 1g of sodium borohydride in 20ml of water, and add to the above dispersion liquid, stir for 30 minutes and let it stand for 2h to obtain Pd loaded C 3 N 4 @CF composite photocatalyst.

[0031] (2)Pd / C 3 N 4 @Preparation of biomass carbon fiber composite membrane

[0032] Select 0.05g of the above composite material and disperse it in 20ml of DMF, then dissolve 2g of PAN in the solution, and stir for 4h to ob...

Embodiment 2

[0034] Preparation C 3 N 4 When @CF, keep other conditions unchanged, study C by changing the concentration of urea solution3 N 4 Effect on the catalytic performance of biomass carbon materials; preparation of Pd-supported C 3 N 4 When @CF compound photocatalyst, choose the weighed C 3 N 4 @CF and PdCl 2 The masses are: 1g / 0.2g and 2g / 0.2g, by adjusting the mass ratio of the two to examine the Pd loading for C 3 N 4 Effect of @CF composite catalytic materials on catalytic activity.

Embodiment 3

[0036] Preparation of Pd loaded C 3 N 4 @CF composite photocatalytic film (other conditions remain unchanged), by changing the amount of composite catalyst added (0.1g, 0.2g, 0.3g) to investigate the effect of the amount of composite catalyst on the adsorption degradation effect, screening the optimal amount; to ensure With other conditions unchanged, the viscosity of the casting solution is adjusted by changing the amount of PAN added (1g, 3g), thereby controlling the diameter of the polymer fiber of the composite membrane and adjusting the pore size. Finally choose the most matching ratio, making the constructed Pd / C 3 N 4 The degradation effect of @CF composite photocatalytic film on tetracycline reached more than 90% within 120min of visible light (λ>420nm) irradiation.

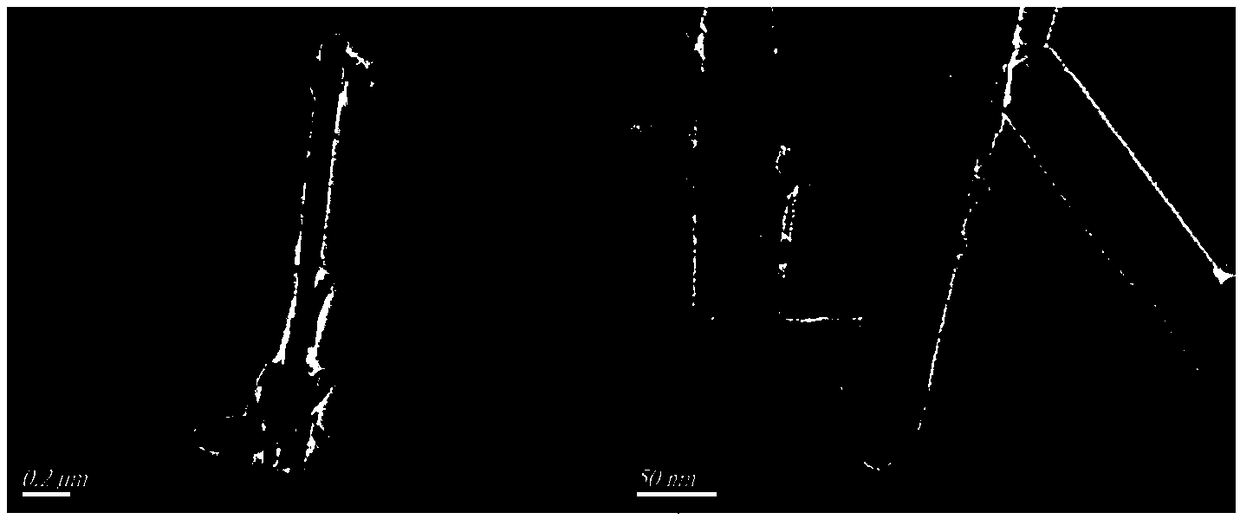

[0037] Such as figure 1 As shown, Pd nanoparticles grow uniformly on C 3 N 4 @CF surface, the loading of CN can be further characterized by XRD.

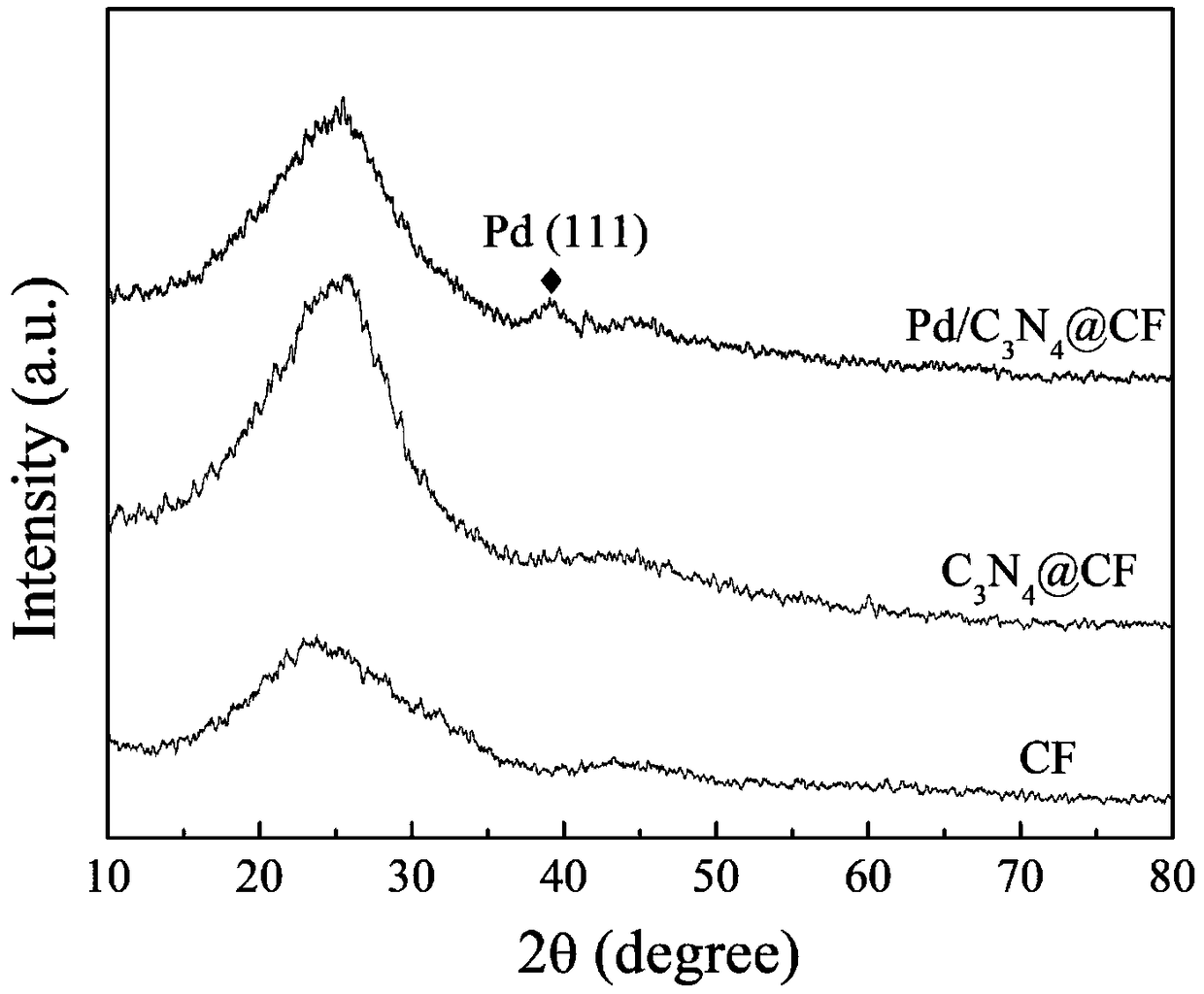

[0038] Such as figure 2 As shown, the peak of Pd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com