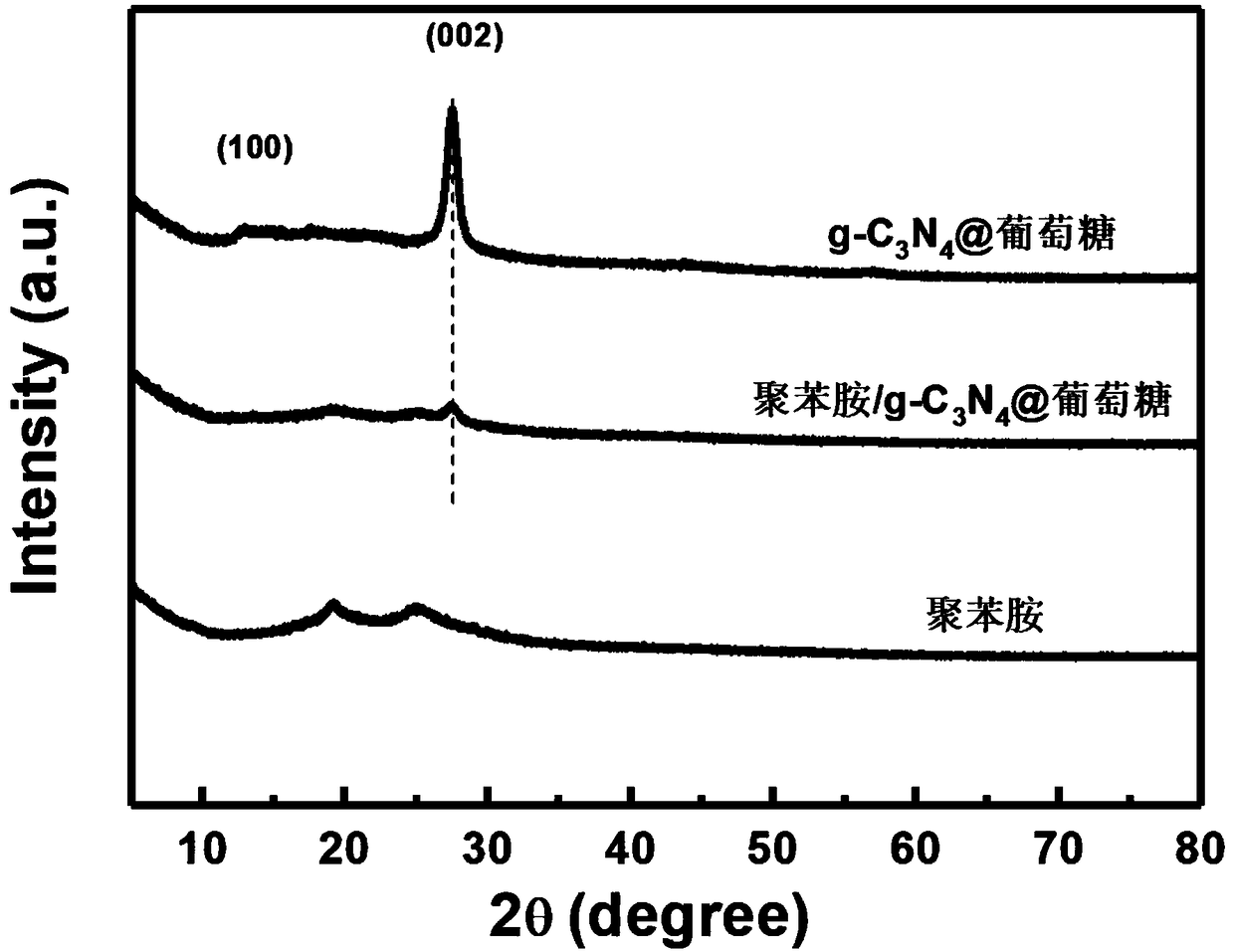

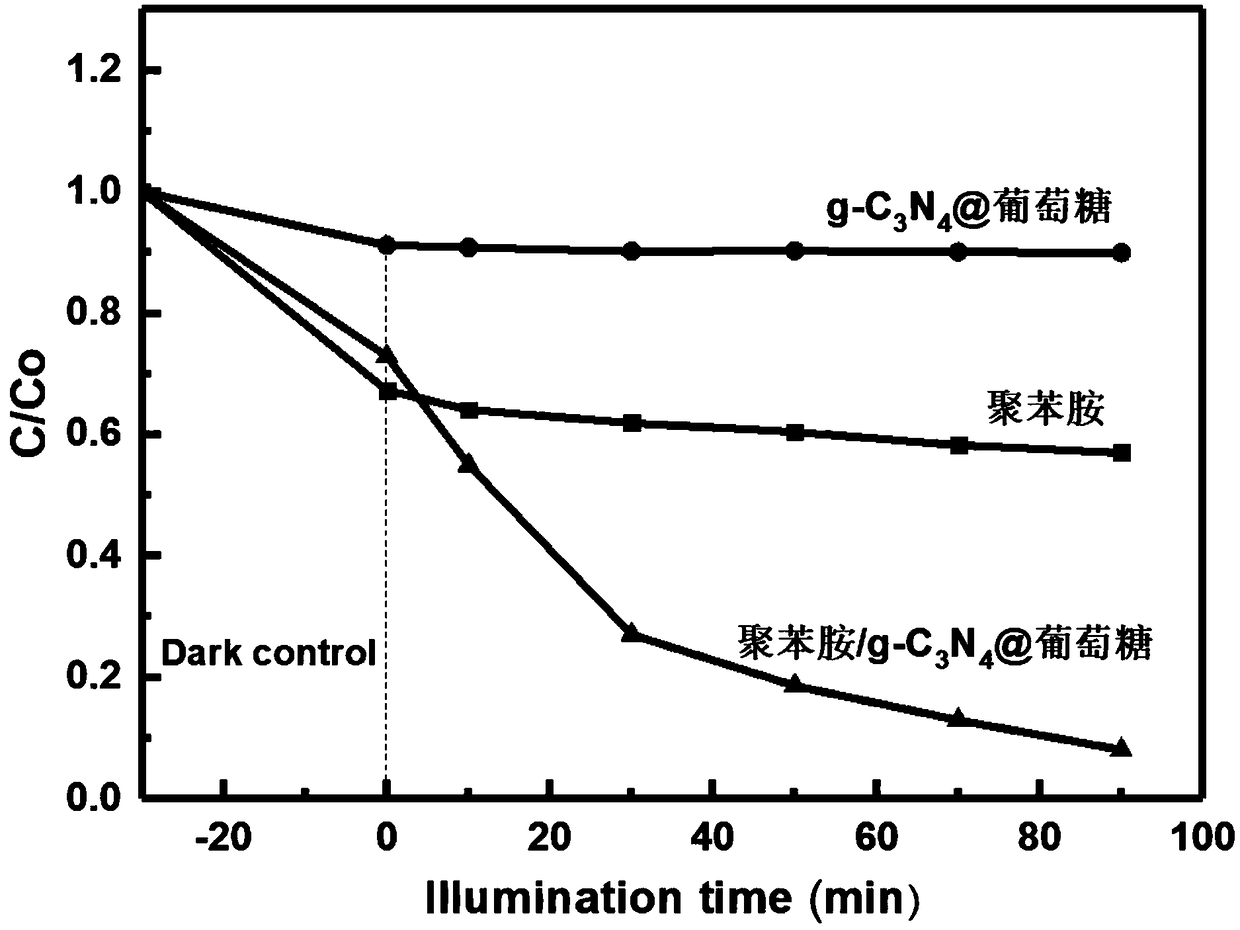

Polyaniline/g-C3N4-coated glucose composite material preparation method

A composite material, g-c3n4 technology, applied in the preparation of g-C3N4 composite catalyst, the field of photocatalyst preparation, to achieve the effects of excellent photocatalytic performance, easy compatibility and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

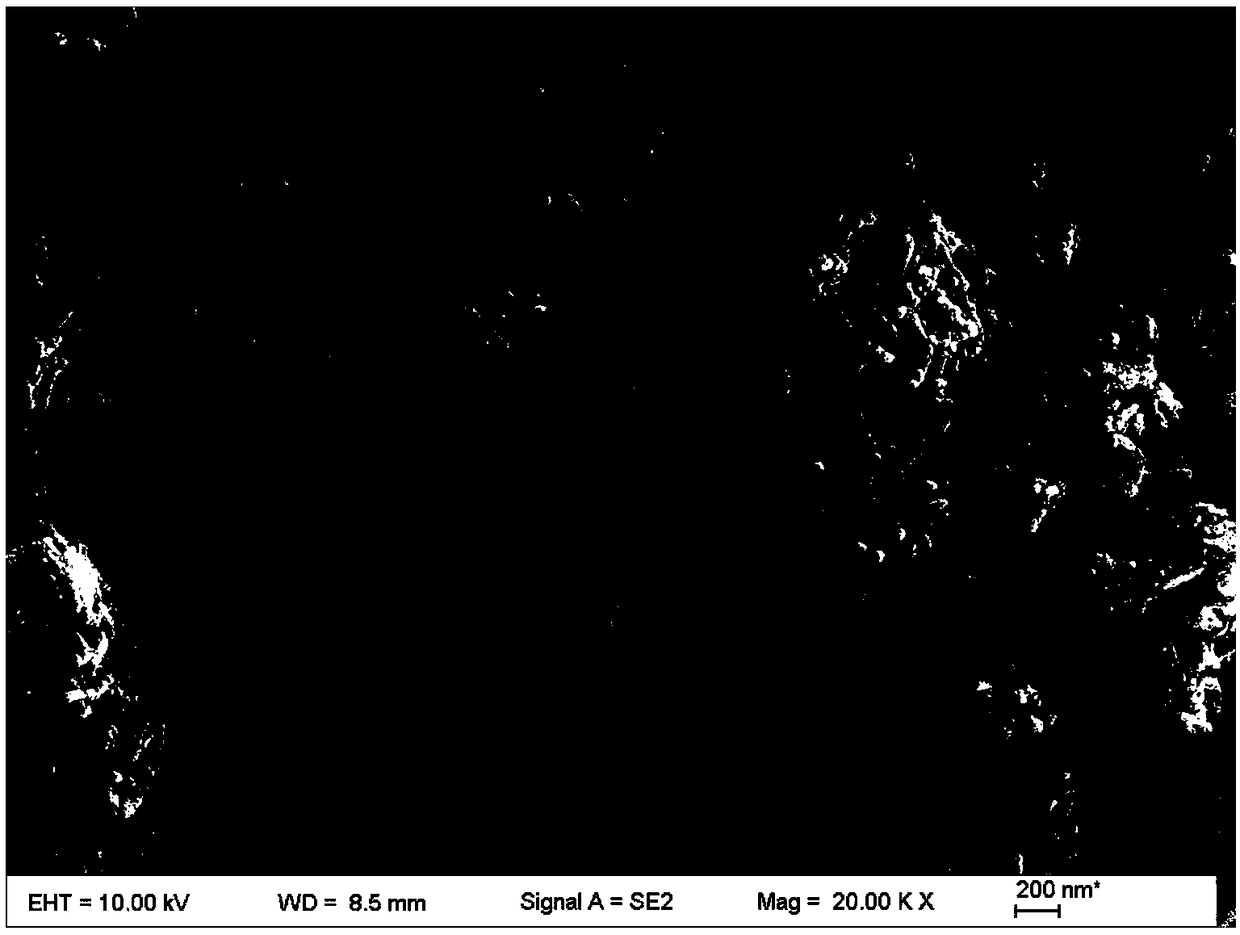

Image

Examples

Embodiment 1

[0033] In this example, a polyaniline / g-C 3 N 4 The preparation method of @glucose composite material comprises the following steps:

[0034] (1) g-C 3 N 4 Preparation of @glucose composite material:

[0035] a. Weigh 10g of dicyandiamide powder as a raw material, place it in a porcelain crucible with a volume of 100ml, and place it in a muffle furnace at 5°C min -1 The heating rate was raised to the reaction heating temperature of 550 °C, and then kept at the reaction temperature for 4 hours, and then cooled to room temperature to obtain yellow g-C 3 N 4 Material;

[0036] b. Weigh 0.5g of g-C prepared in the step a 3 N 4 material, the g-c 3 N 4 The material was added to 40 mL of glucose solution with a molar concentration of 0.3M to form g-C 3 N 4 and glucose, and ultrasonically mix the mixture for 6 hours to form a suspension, then transfer the suspension to a high-pressure reactor with a volume of 50mL, and heat it at 180°C for 10 hours, and centrifuge the reac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com