Gull rock negative-ion ecological putty and preparation method thereof

A technology of negative ions and seagulls, applied in the direction of filling slurry, etc., can solve the problems of peeling, peeling, and easy cracking of putty, and achieve the effect of easy painting, improving the environment, and improving the bonding strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

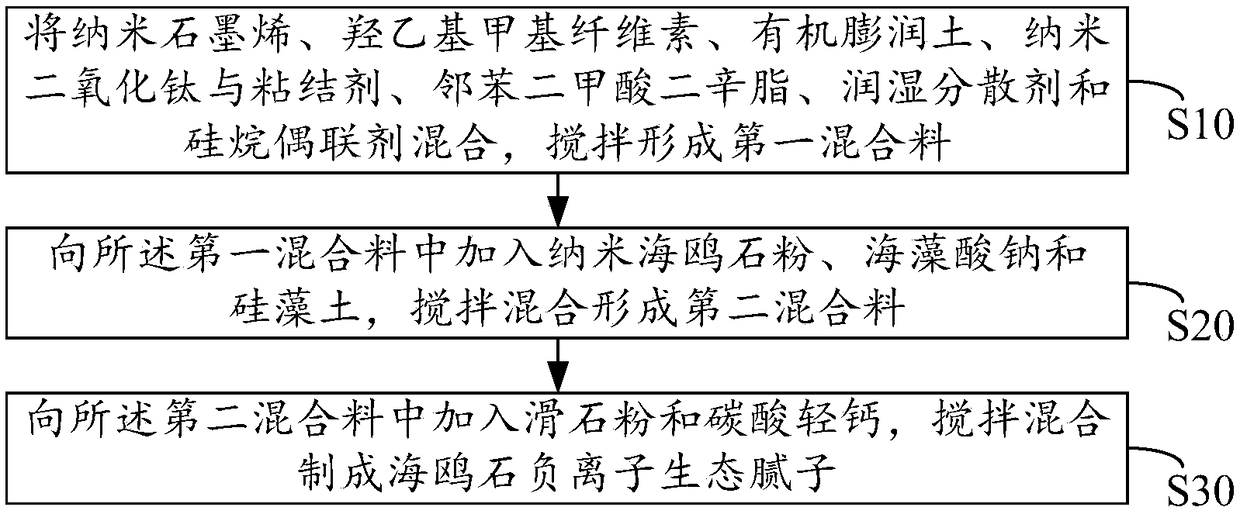

[0030] The present invention also proposes a kind of preparation method of seagull stone negative ion ecological putty as mentioned above, figure 1 It is an embodiment of the preparation method of seagullite anion ecological putty provided by the invention. see figure 1 , in the present embodiment, the preparation method of the seagull stone anion ecological putty comprises the following steps:

[0031]Step S10, mixing nano-graphene, hydroxyethyl methylcellulose, organic bentonite, nano-titanium dioxide with binder, dioctyl phthalate, wetting and dispersing agent and silane coupling agent, stirring to form the first mixture material;

[0032] In step S10, a high-speed disperser can be used to mix the raw materials. The specific operation method is as follows: mix nano-graphene, hydroxyethyl methylcellulose, organic bentonite, nano-titanium dioxide with a binder, and dioctyl phthalate , Wetting and dispersing agent and silane coupling agent are added to the container in prop...

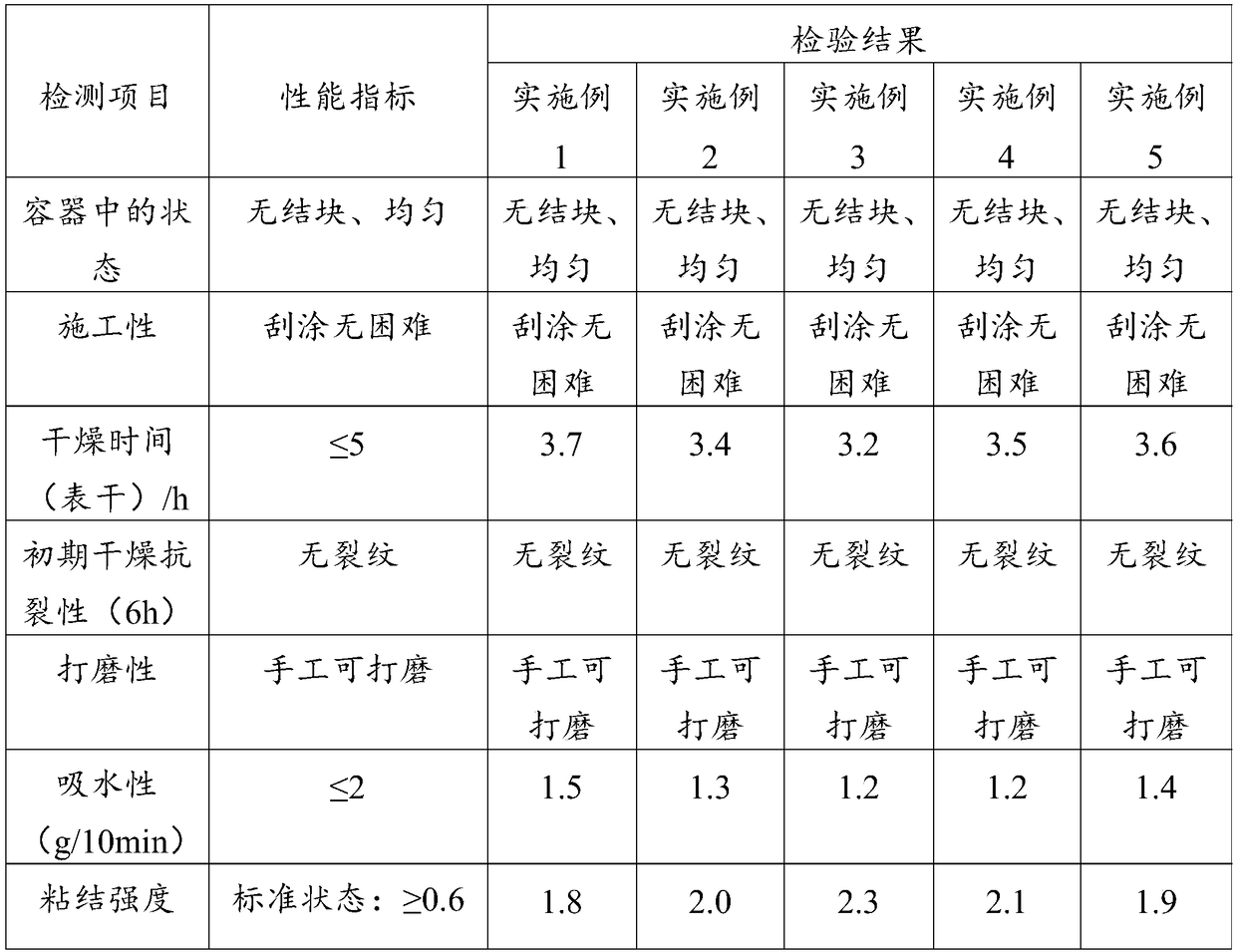

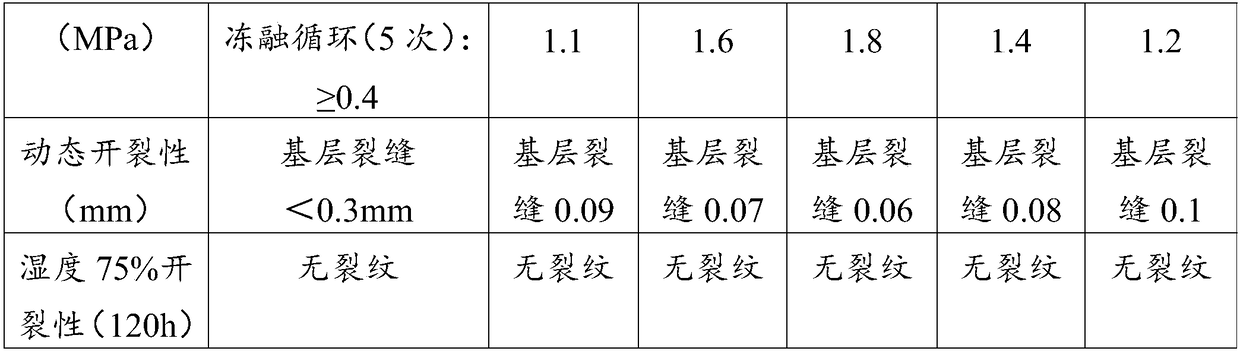

Embodiment 1

[0039] (1) Weighing raw materials: talcum powder 15kg, light calcium carbonate 32kg, ancient sea rock powder 8kg, sodium alginate 15kg, diatomite 16kg, nano-graphene 0.5kg, hydroxyethyl methylcellulose 2kg, organic bentonite 1kg, Nano titanium dioxide 2kg, epoxy emulsion 7kg, dioctyl phthalate 45kg, fatty alcohol polyoxyethylene phosphate 2kg and vinyl triethoxysilane 0.5kg.

[0040] (2) Nano-graphene, hydroxyethyl methylcellulose, organic bentonite, nano-titanium dioxide and binder, dioctyl phthalate, wetting and dispersing agent and silane coupling agent are added in proportion to the container, Stir with a high-speed disperser at a speed of 50-100 rpm for 2-4 minutes, then gradually and slowly adjust the speed of the high-speed disperser to 1500-2500 rpm, and continue stirring for 10-15 minutes to form the first mixture.

[0041] (3) Add nanometer seagull stone powder, sodium alginate and diatomaceous earth to the first mixture, first use a high-speed disperser to stir at a...

Embodiment 2

[0044] (1) Weighing of raw materials: talcum powder 20kg, light calcium carbonate 25kg, nano seagull powder (mass ratio of ancient sea rock powder and fiber tourmaline powder is 1:1) 12kg, sodium alginate 13kg, diatomite 13kg, nanographene 2kg, hydroxyethyl methylcellulose 1.5kg, organic bentonite 2.5kg, nano titanium dioxide 3kg, polyacrylate emulsion 5kg, dioctyl phthalate 30kg, fatty alcohol polyoxyethylene phosphate 0.5kg and vinyl triethyl Oxysilane 0.7kg.

[0045] (2) Nano-graphene, hydroxyethyl methylcellulose, organic bentonite, nano-titanium dioxide and binder, dioctyl phthalate, wetting and dispersing agent and silane coupling agent are added in proportion to the container, Stir with a high-speed disperser at a speed of 50-100 rpm for 2-4 minutes, then gradually and slowly adjust the speed of the high-speed disperser to 1500-2500 rpm, and continue stirring for 10-15 minutes to form the first mixture.

[0046] (3) Add nanometer seagull stone powder, sodium alginate a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com