Deicing pure copper coating

A pure copper and coating technology, applied in the coating, metal material coating process, fusion spraying, etc., can solve the problems of unsuitable deicing protection, poor heat transfer capacity, and complex structure of the wing, and achieve electrical conductivity Moderate performance, uniform heating, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

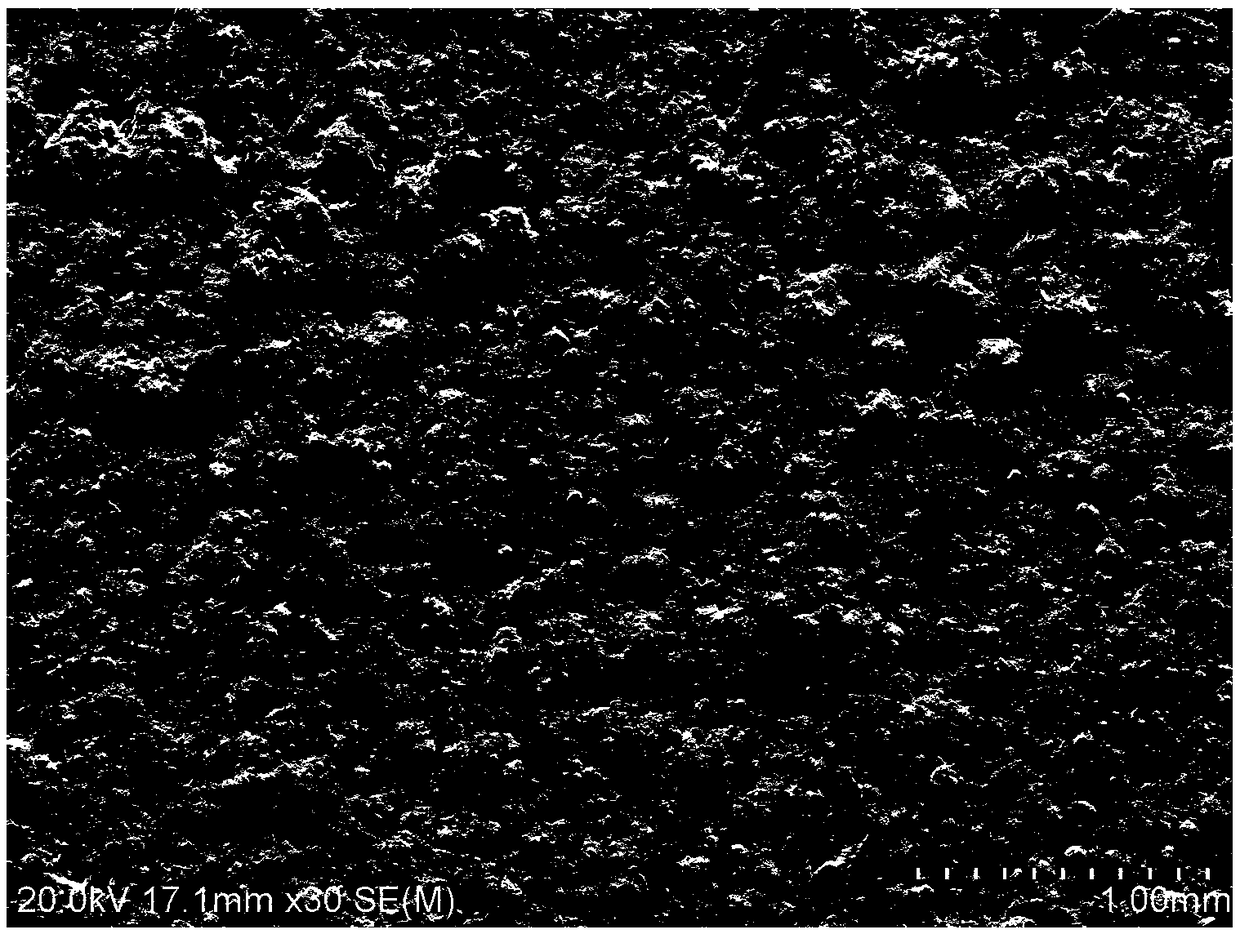

Image

Examples

Embodiment 1

[0025] (1) The surface to be sprayed of the glass fiber reinforced resin substrate is first cleaned with acetone to remove the oil stain on the substrate surface; then sandblasting is performed with white jade corundum to increase the roughness of the substrate surface;

[0026] (2) The substrate processed in step (1) is mounted on the workbench, and the surface to be sprayed of the substrate is cleaned with compressed air, and the residual particles adsorbed on the surface of the substrate after sand blasting are removed;

[0027] (3) Put the copper wire with a diameter of 1.2mm into the wire feeding device, first use the arc spray gun to spray the surface to be sprayed on the substrate once to preheat, and then use the arc spray gun to spray the copper wire to the surface to be sprayed on the substrate. A pure copper coating with a thickness of 0.1mm is obtained on the substrate; among them, the current of arc spraying is 90A, and the voltage is 20V;

[0028] (4) Connect the...

Embodiment 2

[0031] (1) The surface to be sprayed of the glass fiber reinforced resin substrate is first cleaned with acetone to remove the oil stain on the substrate surface; then sandblasting is performed with white jade corundum to increase the roughness of the substrate surface;

[0032] (2) The substrate processed in step (1) is mounted on the workbench, and the surface to be sprayed of the substrate is cleaned with compressed air, and the residual particles adsorbed on the surface of the substrate after sand blasting are removed;

[0033] (3) Put the copper wire with a diameter of 1.6mm into the wire feeding device, first use the arc spray gun to spray the surface to be sprayed on the substrate once to preheat, and then use the arc spray gun to spray the copper wire to the surface to be sprayed on the substrate. A pure copper coating with a thickness of 0.12mm is obtained on the substrate; among them, the current of arc spraying is 135A, and the voltage is 32V;

[0034] (4) Connect t...

Embodiment 3

[0037] (1) The surface to be sprayed of the glass fiber reinforced resin substrate is first cleaned with acetone to remove the oil stain on the substrate surface; then sandblasting is performed with white jade corundum to increase the roughness of the substrate surface;

[0038] (2) The substrate processed in step (1) is mounted on the workbench, and the surface to be sprayed of the substrate is cleaned with compressed air, and the residual particles adsorbed on the surface of the substrate after sand blasting are removed;

[0039] (3) Put the copper wire with a diameter of 2 mm into the wire feeding device, first use the arc spray gun to spray the surface to be sprayed on the substrate once to preheat, and then use the arc spray gun to spray the copper wire to the surface to be sprayed on the substrate, A pure copper coating with a thickness of 0.3mm is obtained on the surface; among them, the current of arc spraying is 180A, and the voltage is 45V;

[0040] (4) Connect the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com