Preparation method of shear-resistant softener

A lubricant and anti-shear technology, which is applied in the field of preparation of anti-shear lubricants, can solve problems such as sticking rolls, cylinders, resistance to high shear, poor compatibility, etc., to improve the degree of reaction, Effect of improving shear resistance and improving rheological properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

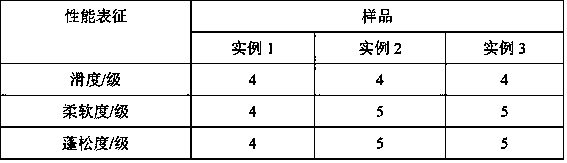

Examples

example 1

[0018] Take the rice bran and grind it, pass through a 200-mesh sieve to get the rice bran powder, add the rice bran powder to 1% sodium hydroxide solution with a mass fraction of 1% by mass ratio, stir and mix, place it at 75°C for 3 hours, and filter to obtain The filtrate was adjusted to pH 1.5 with 20% hydrochloric acid by mass fraction, filtered again and collected to obtain the acidolysis filtrate, according to the mass ratio of 1:10, the acidolysis filtrate was added to ethyl acetate, stirred and mixed and extracted, and the acetic acid was distilled off under reduced pressure Ethyl ester to obtain the extract, filter and collect the extraction filter residue and add it to methanol at a mass ratio of 1:5, stir and mix and filter with a filter membrane with a pore size of 0.25 microns to collect the modified solution; weigh in parts by weight 45 parts of deionized water, 10 parts of modified liquid, 3 parts of 200 mesh peach gum powder and 6 parts of polyvinyl alcohol wer...

example 2

[0020] Take rice bran and grind it, pass through a 200-mesh sieve to get rice bran powder, add rice bran powder to 1% sodium hydroxide solution with a mass fraction of 1% by mass ratio, stir and mix, place it at 77°C for 4 hours, and filter to obtain The filtrate was adjusted to pH 1.5 with 20% hydrochloric acid by mass fraction, filtered again and collected to obtain the acidolysis filtrate, according to the mass ratio of 1:10, the acidolysis filtrate was added to ethyl acetate, stirred and mixed and extracted, and the acetic acid was distilled off under reduced pressure Ethyl ester to obtain the extract, filter and collect the extraction filter residue and add it to methanol at a mass ratio of 1:5, stir and mix and filter with a filter membrane with a pore size of 0.25 microns to collect the modified solution; weigh in parts by weight 47 parts of deionized water, 12 parts of modified liquid, 4 parts of 200-mesh peach gum powder and 7 parts of polyvinyl alcohol were placed in ...

example 3

[0022] Take rice bran and grind it, pass through a 200-mesh sieve to obtain rice bran powder, add rice bran powder to 1% sodium hydroxide solution by mass fraction at a mass fraction of 1:15, stir and mix, place it at 85°C for 5 hours, and filter to obtain The filtrate was adjusted to pH 1.5 with 20% hydrochloric acid by mass fraction, filtered again and collected to obtain the acidolysis filtrate, according to the mass ratio of 1:10, the acidolysis filtrate was added to ethyl acetate, stirred and mixed and extracted, and the acetic acid was distilled off under reduced pressure Ethyl ester to obtain the extract, filter and collect the extraction filter residue and add it to methanol at a mass ratio of 1:5, stir and mix and filter with a filter membrane with a pore size of 0.25 microns to collect the modified solution; weigh in parts by weight 50 parts of deionized water, 15 parts of modified liquid, 5 parts of 200-mesh peach gum powder and 8 parts of polyvinyl alcohol were plac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com