Optical-fiber-waveguide automatic alignment coupling instrument based on image processing

An image processing and automatic alignment technology, applied in the coupling of optical waveguides, light guides, optics, etc., can solve the problems of slow alignment speed, complex chip manufacturing process, high coupling loss, and avoid long-term operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0076] The present invention will be further described in detail below in conjunction with the accompanying drawings.

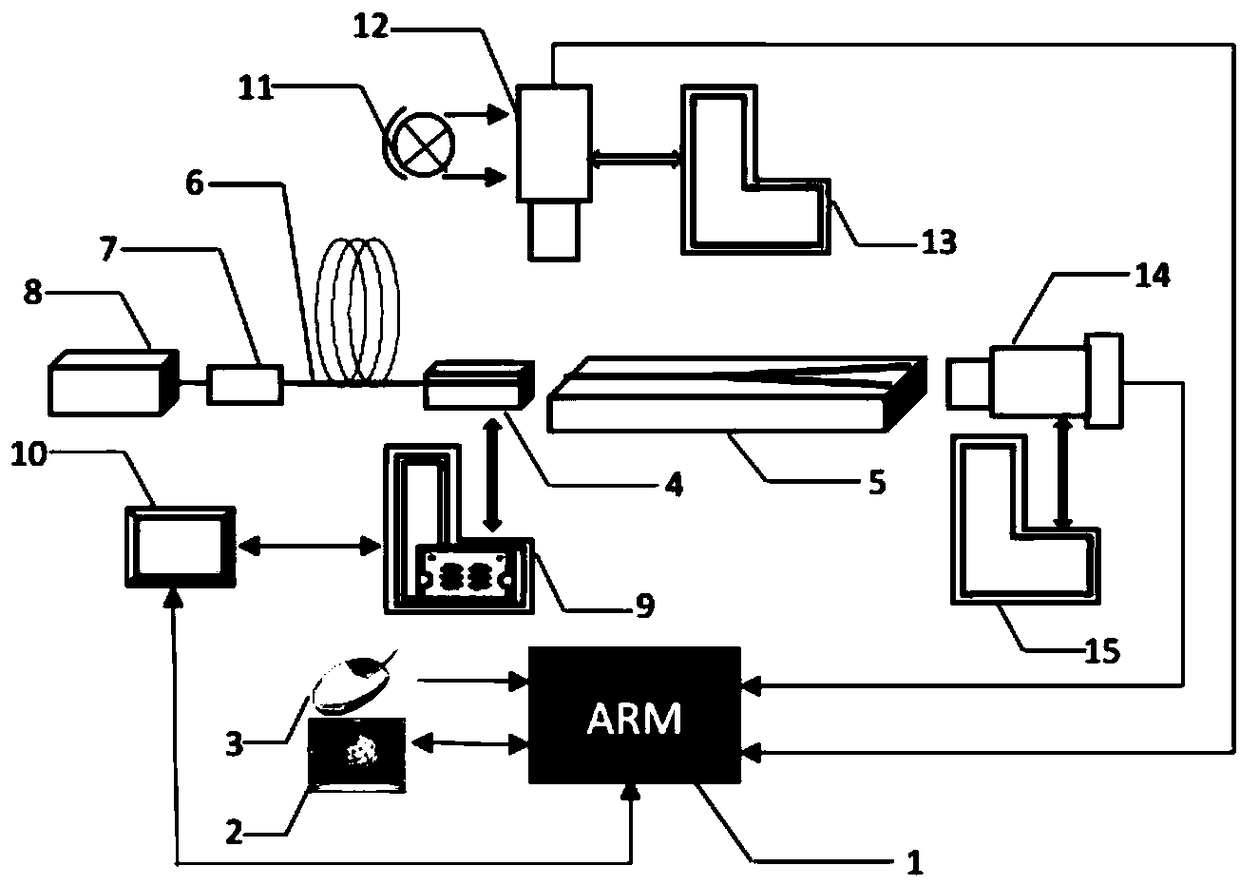

[0077] A fiber-waveguide automatic alignment coupling instrument based on image processing of the present invention, such as figure 1 As shown, it includes image acquisition module, image processing and control module, motion execution module and human-computer interaction module.

[0078] The image acquisition unit includes a white light source 11, a laser 8, an optical fiber adapter 7, and two sets of microscope-CMOS cameras.

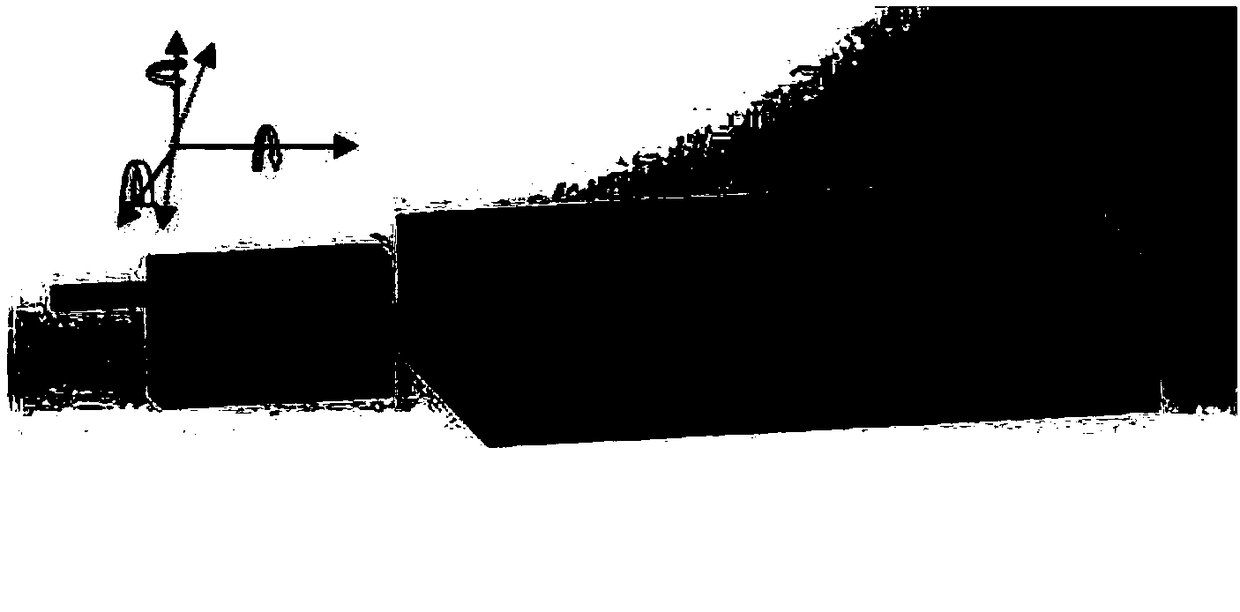

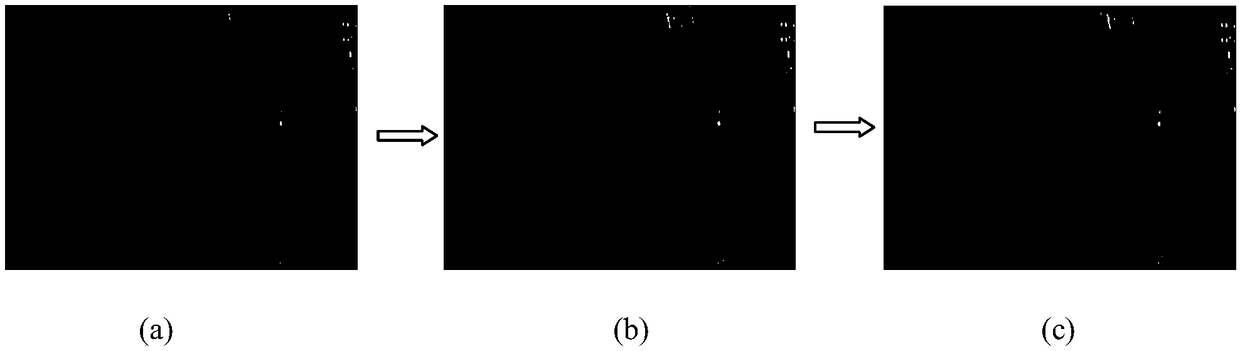

[0079] The laser 8 directly couples the red light into the pigtailed liner 4 through the bare fiber adapter 7; the pigtailed liner 4 is opposite to the Y waveguide element 5 for coupling; two groups of CMOS cameras are connected with the microscope objective lens, the first A group microscope-CMOS camera 12 is vertically fixed above the pad-waveguide coupling point to perform microscopic imaging on the coupling point. The white lig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com