Chitosan zwitterionic bactericide, preparation method and applications thereof

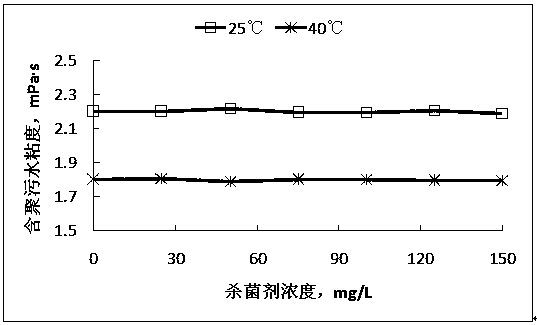

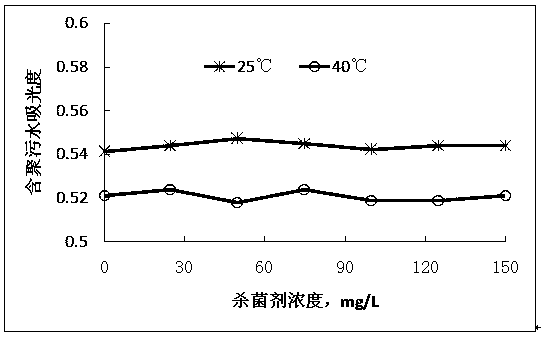

A technology of zwitterion and chitosan, applied in the fields of botanical equipment and methods, application, biocide, etc., can solve the problem of less research on bactericidal performance, and achieve the effect of good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1 prepares chitosan zwitterionic bactericide

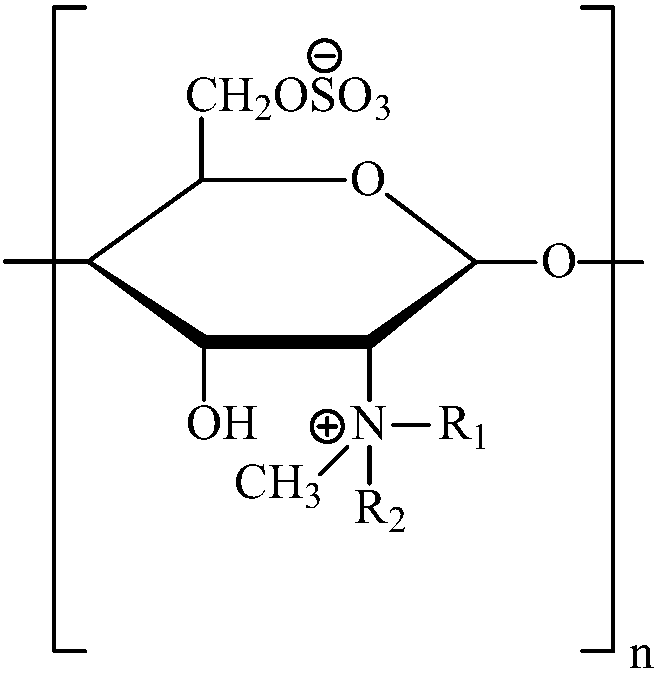

[0031] The molecular structural formula is as follows:

[0032]

[0033] Preparation method: Dissolve chitosan (deacetylation degree 95%, viscosity 100mpa·s) with 2% acetic acid, add 3% urea peroxide, stir at 50°C for 8 hours, precipitate with absolute ethanol, wash until no impurities, Dry to obtain chitosan powder. Get 8.95g of degraded chitosan, dissolve it in 2% acetic acid, add 36.8g of dodecanal, 0.8g of hexadecyl ammonium chloride, adjust the pH value to 4.5 (with acetic acid) after reacting at 40°C for 10h, slowly 11.5 g of sodium borohydride solution (mass concentration 35%, 11.5 g refers to the amount of sodium borohydride solution used, the same below) was added dropwise, and the reaction was continued for 1 hour before the reaction was terminated. Adjust the pH value to 10 (adjusted with sodium hydroxide solution), precipitate the target product, dissolve it with isopropanol after washing and dry...

Embodiment 2

[0034] Embodiment 2 prepares chitosan zwitterionic bactericide

[0035] The molecular structural formula is as follows:

[0036]

[0037] Preparation method: Dissolve chitosan (deacetylation degree 95%, viscosity 200mpa·s) with 2% acetic acid, add 2% urea peroxide, stir at 50°C for 10h, precipitate with absolute ethanol, wash until no impurities, Dry to obtain chitosan powder. Take 8.95g of degraded chitosan and dissolve it in 2% acetic acid, add 42.4g of tetradecylaldehyde and 0.8g of cetyl ammonium chloride, adjust the pH value to 4.5 (adjusted with acetic acid) after reacting at 40°C for 10h, slowly drop Add 11.5g of sodium borohydride solution and continue the reaction for 2h before terminating the reaction. Adjust the pH value to 11, precipitate the target product, dissolve it with isopropanol after washing and drying, add 22g of methyl iodide and 3.6ml of NaOH solution with a concentration of 1.5mol / L, and stir for 14 hours in the dark to form N-alkyl quaternary amm...

Embodiment 3

[0038] Embodiment 3 prepares chitosan zwitterionic bactericide

[0039] The molecular structural formula is as follows:

[0040]

[0041]Preparation method: Dissolve chitosan (deacetylation degree 95%, viscosity 150mpa·s) with 2% acetic acid, add 5% urea peroxide, stir at 50°C for 4 hours, precipitate with absolute ethanol, wash until no impurities, Dry to obtain chitosan powder. Take 8.95g of degraded chitosan and dissolve it in 2% acetic acid, add 36.8g of dodecanal and 0.8g of hexadecyl ammonium chloride, adjust the pH value to 4.5 (adjusted with acetic acid) after reacting at 40°C for 10h, slowly drop Add 11.5g of sodium borohydride solution, continue the reaction for 1.5h, adjust the pH value to 4.5 (adjusted with acetic acid), continue to add 36.8g of dodecanal and repeat the above reaction (react at 40°C for 10h). After the reaction is completed, adjust the pH value to 10 to precipitate the target product. After washing and drying, dissolve it with isopropanol, add...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com