Application of g-C3N4/Fe3O4 composite material to polycyclic aromatic hydrocarbon contaminated soil remediation

A polycyclic aromatic hydrocarbon and composite material technology, applied in the field of soil remediation, can solve the problems of insufficient utilization of sunlight, secondary pollution, unsatisfactory photocatalytic activity, etc., and achieve excellent visible light absorption performance and reduce toxicity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Under visible light, g-C 3 N 4 / Fe 3 o 4 Composite materials used in Philippine contaminated soil remediation

[0048] g-C 3 N 4 / Fe 3 o 4 A method for repairing phenanthrene-contaminated soil with composite materials

[0049] (1) The phenanthrene-contaminated soil sampled from the polluted plots has been tested for a phenanthrene content of 300 mg phenanthrene / kg soil.

[0050] (2) Air-dry the appropriate amount of PAH-contaminated soil naturally for about a week. Subsequently, the soil was crushed and crushed. Sieve the pulverized soil with a 60-mesh soil sieve to obtain soil particles;

[0051] (3) Fe 3 o 4 Nanoparticles and g-C 3 N 4 Mix according to the mass ratio of 1:100, ultrasonically oscillate and mix for 2 hours in the mixed solution of ethanol and water (volume ratio 1:2), after solid-liquid separation, dry to obtain g-C 3 N 4 / Fe 3 o 4 composite material.

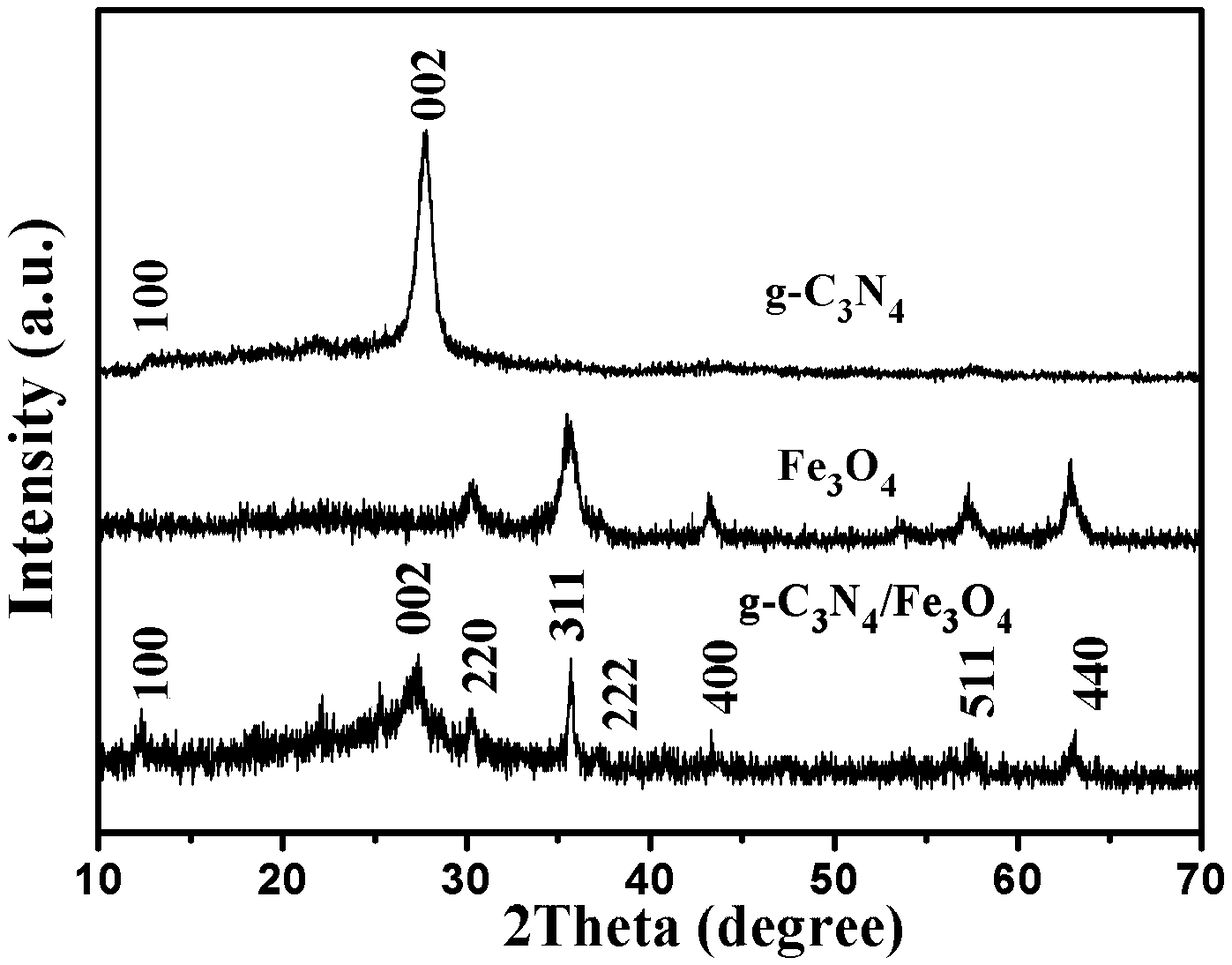

[0052] figure 1 for g-C 3 N 4 , Fe 3 o 4 and g-C 3 N 4 / Fe 3 o 4 XRD spec...

Embodiment 2

[0067] In sunlight, g-C 3 N 4 / Fe 3 o 4 Application of composite materials in remediation of high-concentration phenanthrene-contaminated soil

[0068] (1) In the phenanthrene-contaminated soil sampled from the polluted land, the phenanthrene content was as high as 2150mg phenanthrene / kg soil.

[0069] (2) Air-dry the appropriate amount of PAH-contaminated soil naturally for about a week. Subsequently, the soil was crushed and crushed. Sieve the pulverized soil with a 120-mesh soil sieve to obtain soil particles;

[0070] (3) Fe 3 o 4 Nanoparticles and g-C 3 N 4 Mix according to the mass ratio of 30:100, ultrasonically oscillate and mix for 2 hours in the mixed solution of ethanol and water (volume ratio 1:2), after solid-liquid separation, dry to obtain g-C 3 N 4 / Fe 3 o 4 composite material.

[0071] (4) the g-C obtained in step (3) 3 N 4 / Fe 3 o 4 The mass percentage of composite material and polluted soil is 6%, the g-C 3 N 4 / Fe 3 o 4 Mix the composi...

Embodiment 3

[0078] Under UV light source, g-C 3 N 4 / Fe 3 o 4 Composite materials used to remediate high-concentration phenanthrene-contaminated soil

[0079] (1) In the phenanthrene-contaminated soil sampled from the polluted land, the phenanthrene content was as high as 2150mg phenanthrene / kg soil.

[0080] (2) Air-dry the appropriate amount of PAH-contaminated soil naturally for about a week. Subsequently, the soil was crushed and crushed. Sieve the pulverized soil with a 120-mesh soil sieve to obtain soil particles;

[0081] (3) Fe 3 o 4 Nanoparticles and g-C 3 N 4 Mix according to the mass ratio of 30:100, ultrasonically oscillate and mix for 2 hours in the mixed solution of ethanol and water (volume ratio 1:2), after solid-liquid separation, dry to obtain g-C 3 N 4 / Fe 3 o 4 composite material.

[0082] (4) the g-C obtained in step (3) 3 N 4 / Fe 3 o 4 The mass percentage of composite material and polluted soil is 6%, the g-C 3 N 4 / Fe 3 o 4 Mix the composite ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com