Method of using membrane distributor to greenly prepare cuprous oxide with controllable morphology

A technology of cuprous oxide and distributor, applied in the direction of copper oxide/copper hydroxide, etc., can solve the problems of increasing cost, difficult to form particles, poisonous and other problems, and achieve the effect of low cost, easy enlargement and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

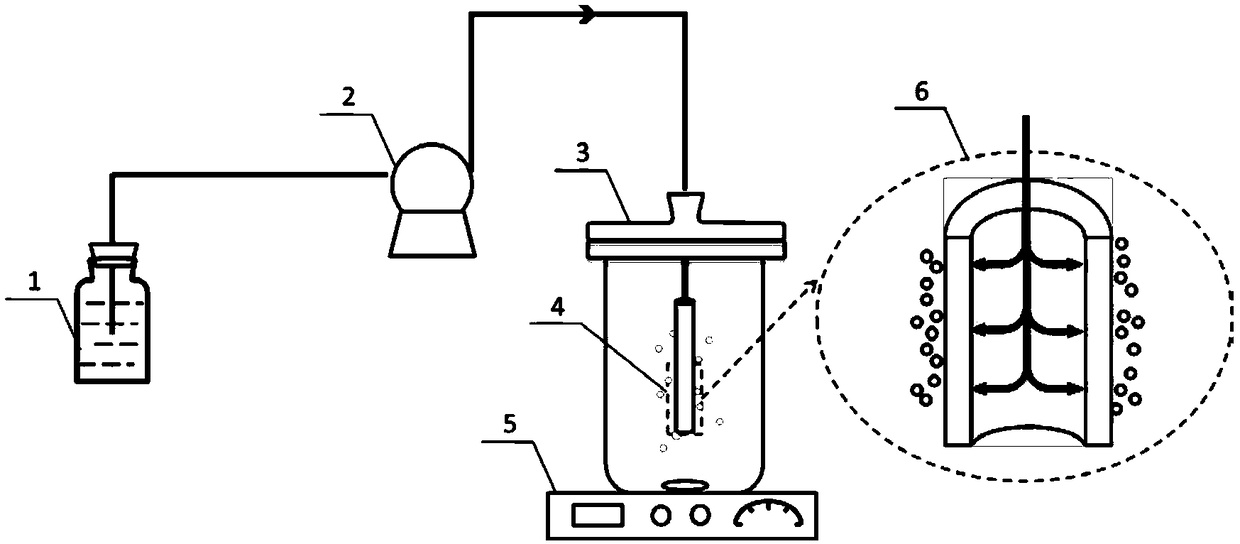

Method used

Image

Examples

Embodiment 1

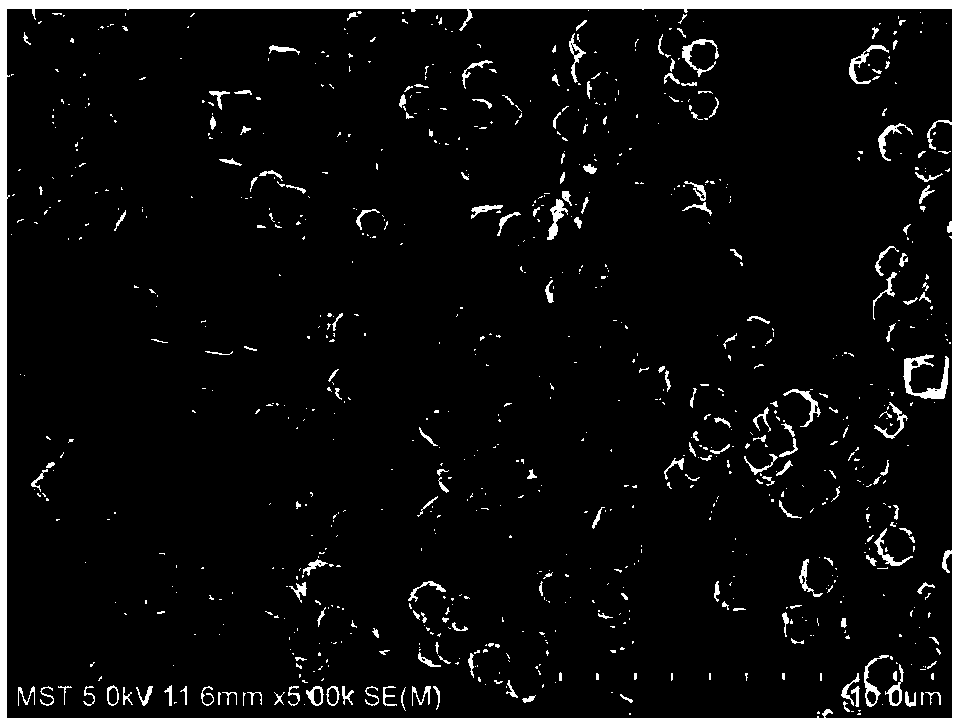

[0033] Configure continuous phase solution 180mL (copper sulfate pentahydrate concentration 0.09mol / L, sodium carbonate concentration 0.12mol / L, sodium citrate concentration 0.036mol / L), glucose solution 180mL, concentration 0.14mol / L, in magnetic stirring Under the action of the glucose solution, the glucose solution is passed into the membrane tube through the high-pressure infusion pump, and the permeation flux of glucose as the dispersed phase is 0.75m 3 m -2 h -1 , through the pores of the membrane to disperse into tiny droplets to mix and react with the continuous phase, the stirring rate is 600r / min, stop stirring after feeding, control the reaction temperature to 70°C, and the reaction and aging time to 60min. After the end, the product was washed with deionized water and absolute ethanol, and dried in a vacuum oven at 60°C for 5 hours to obtain the product Cu 2 O, its scanning electron microscope photo is shown in figure 2 , it can be seen from the figure that the...

Embodiment 2

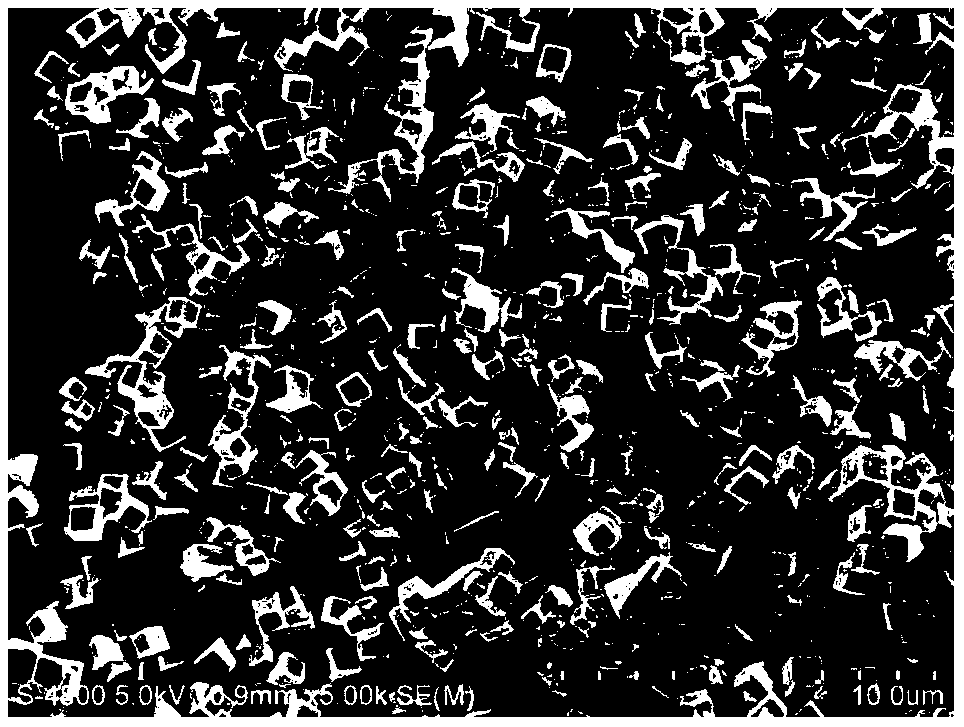

[0035] Configure continuous phase solution 180mL (copper sulfate pentahydrate concentration 0.05mol / L, potassium carbonate concentration 0.06mol / L, potassium citrate concentration 0.072mol / L), glucose solution 180mL, concentration 0.1mol / L, in magnetic stirring Under the action of the glucose solution, the glucose solution is passed into the membrane tube through the high-pressure infusion pump. The permeation flux of the glucose as the dispersed phase is 0.2m3 m-2 h-1, which is dispersed into tiny droplets and continuous The phases were mixed and reacted at a stirring rate of 400 r / min, and the stirring was stopped after the feeding was completed, the reaction temperature was controlled at 60° C., and the reaction and aging time was 60 min. After the end, the product was washed with deionized water and absolute ethanol, and dried in a vacuum oven at 75°C for 2 hours to obtain the product Cu2O, see image 3 , it can be seen from the figure that the prepared Cu2O has a cubic st...

Embodiment 3

[0037] Configure continuous phase solution 180mL (concentration of copper nitrate is 0.068mol / L, concentration of sodium hydroxide is 0.16mol / L, concentration of sodium citrate is 0.072mol / L), glucose solution 180mL, concentration is 0.14mol / L, in a magnetically stirred Under the action, the glucose solution is passed into the membrane tube through the high-pressure infusion pump. The permeation flux of glucose as the dispersed phase is 1.1m3·m-2·h-1, and it is dispersed into tiny droplets and continuous phase through the membrane pores. Mix and react, the stirring rate is 800r / min, stop stirring after feeding, control the reaction temperature to 80°C, and the reaction and aging time to 60min. After the end, the product was washed with deionized water and absolute ethanol, and dried in a vacuum oven at 60°C for 5 hours to obtain the product Cu2O, see Figure 4 , it can be seen from the figure that the prepared Cu2O has a truncated octahedral structure, the particle size is about...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com