Device for producing organic fertilizer by combined operation of anaerobic fermentation and medium-temperature oxidation

A technology of anaerobic fermentation and combined operation, which is applied in the preparation of organic fertilizers, organic fertilizers, fertilization devices, etc., can solve the problems of toxic and harmful products, high manufacturing costs, easy scaling of UV lamp sleeves, etc., and achieve the goal of eliminating pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention is clearly and completely described below in conjunction with the embodiments of the present invention and the accompanying drawings:

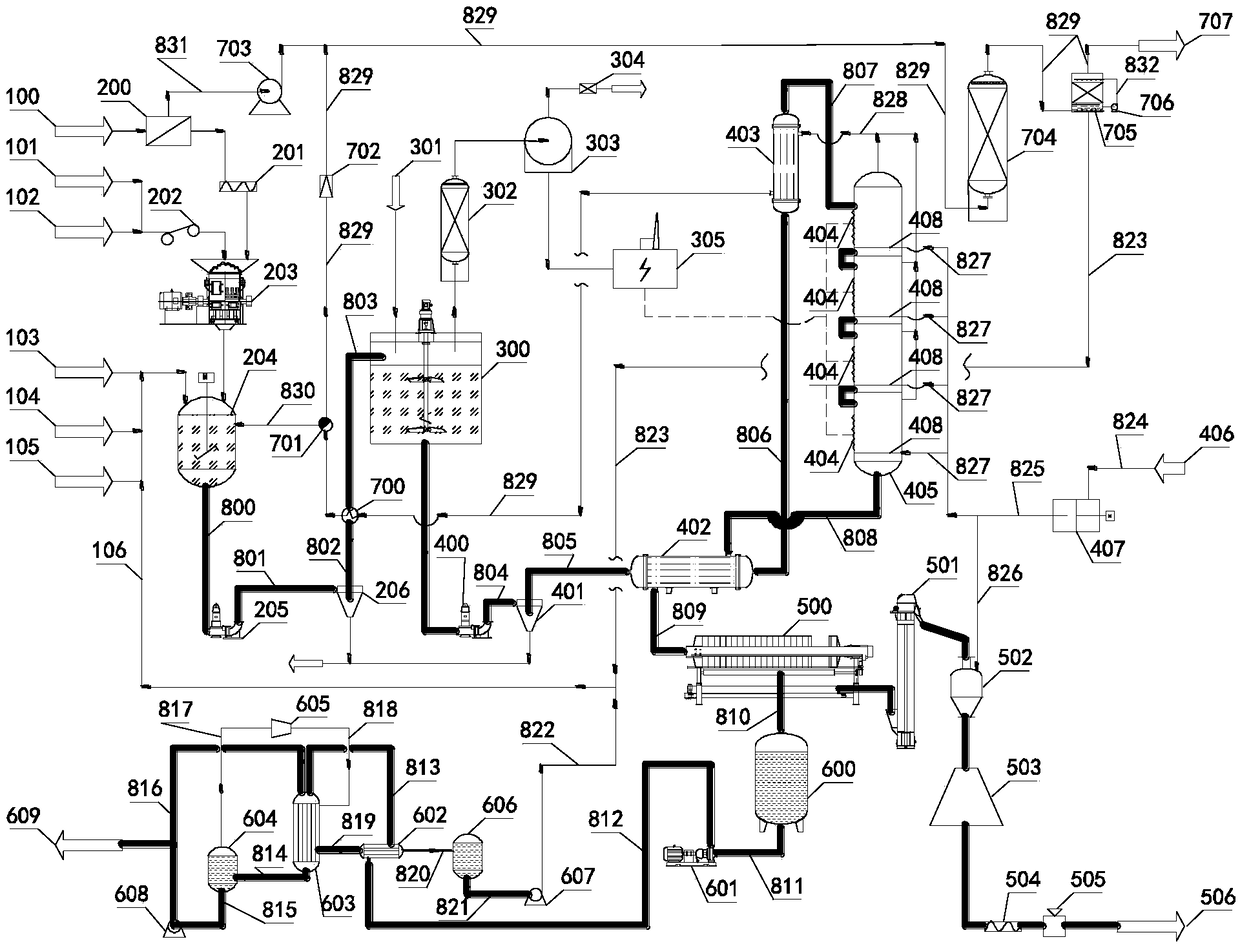

[0028] Such as figure 1As shown, the municipal solid waste (100) of the feeding unit is sorted by the solid waste sorting device (200), and then transported to the crusher (203) by the conveyor (201) for crushing, and the straw (101) and garden waste The material (102) is transported to the crusher (203) through the conveyor (202) for crushing, and the material crushed by the crusher (203) enters the water distribution homogenization tank (204). Livestock and poultry manure (103), domestic sludge and brewery sludge (104), domestic sewage and papermaking black liquor (105) of the feed unit, and recycled water from the concentration unit and the tail gas treatment unit (106) send into water distribution homogenization tank (204) together. The material in the water distribution homogenization tank (204) is transport...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com