Low-cost covering agent used for core-shell structural resin as well as preparation method and application of covering agent

A core-shell structure and coating agent technology is applied in the field of low-cost core-shell structure resin coating agent and its preparation, which can solve the problem of affecting the apparent density, fluidity and anti-agglomeration and agglomeration effect of MBS, and is not conducive to Maintain the light transmittance of MBS modified PVC resin and the uneven mixing of MBS solidified powder, so as to reduce the powder agglomeration and dusting effect, which is beneficial to toughening performance, and improves the fluidity and apparent density.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] 1. Synthesis of MBS emulsion

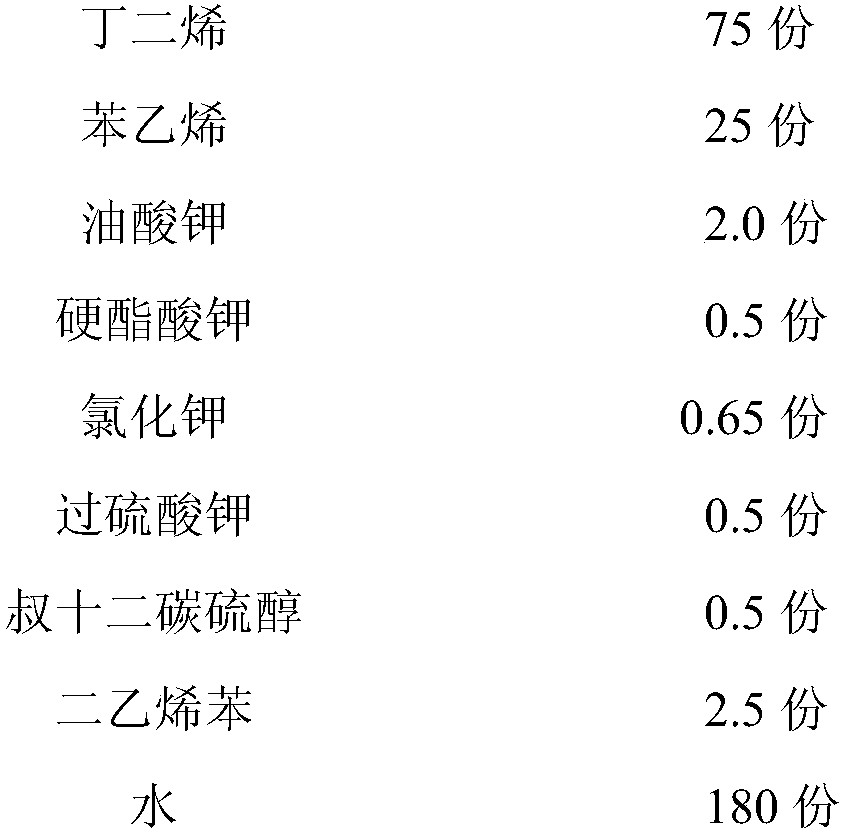

[0053] (1) Synthesis of small particle size styrene-butadiene latex A

[0054] In an autoclave equipped with a stirrer, add the materials in the following proportions:

[0055]

[0056] Start stirring and replace with nitrogen for two times and then heat up. After reaching the reaction temperature, the temperature is kept constant and stirred for 10 hours to obtain a styrene-butadiene latex (referred to as latex A) with a conversion rate of 96.2% and an average particle size of 45 nm.

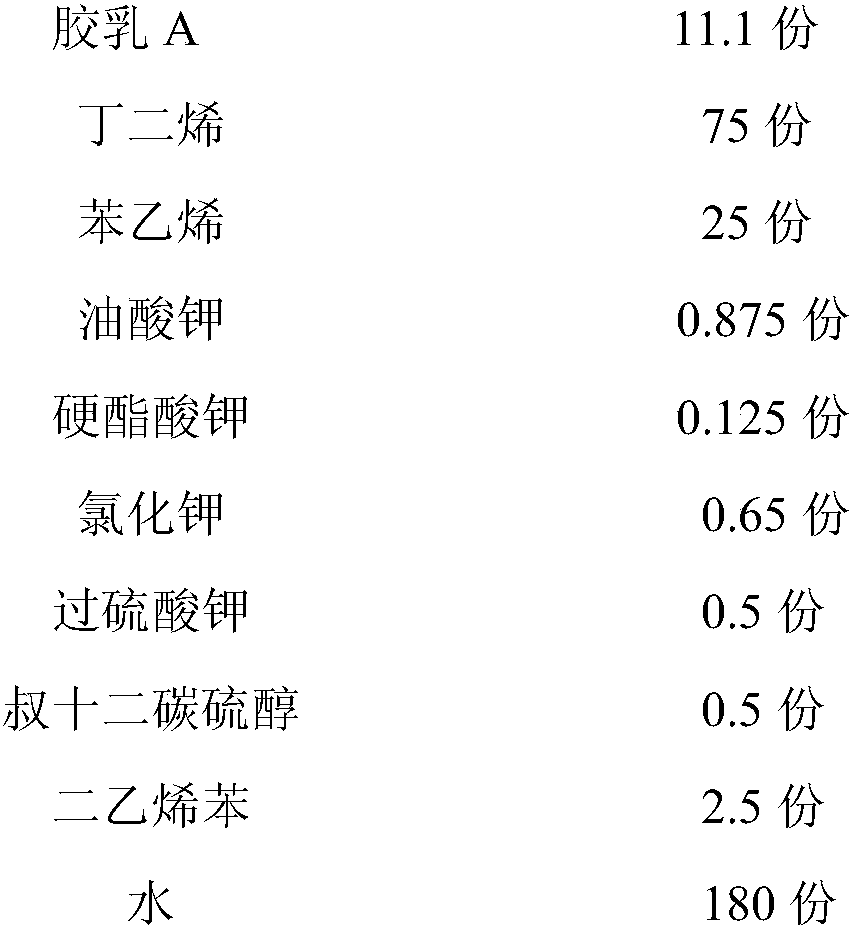

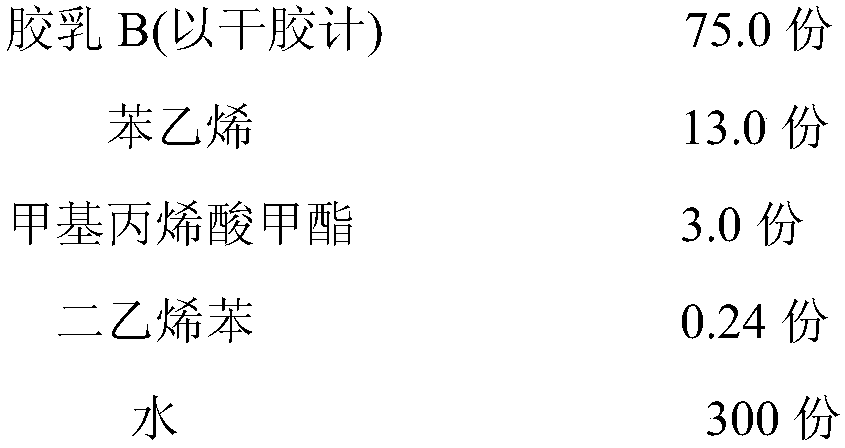

[0057] (2) Synthesis of styrene-butadiene latex B with suitable particle size

[0058] In an autoclave equipped with an agitator, add the ingredients according to the following recipe:

[0059]

[0060] Start stirring and replace with nitrogen for two times and then heat up. After reaching the reaction temperature, the temperature is kept constant and stirred for 12 hours to obtain a styrene-butadiene latex (referred to as latex B) with a conversion...

Embodiment 2

[0088] In the synthesis process of the coating agent in the above-mentioned Example 1, the dosage ratio of styrene and acrylonitrile monomer was changed from the original 5:5 to 7:3, and the rest were exactly the same as in Example 1. The performance test results are shown in Table 1.

Embodiment 3

[0090] In the synthesis process of the coating agent in the above-mentioned Example 1, the consumption ratio of styrene and acrylonitrile monomer was changed from the original 5:5 to 3:7, and the rest were exactly the same as in Example 1. The performance test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com