Manufacturing method of double-junction thin film solar cell module and cell module thereof

A technology of solar cells and manufacturing methods, which is applied to electrical components, circuits, photovoltaic power generation, etc., can solve the problems of inability to achieve battery flexibility and large overall thickness of the battery, and achieve improved conversion efficiency and product yield, improved crystal quality, and improved efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

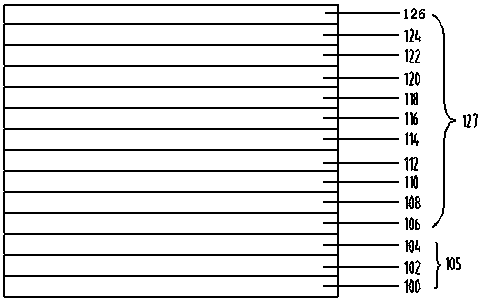

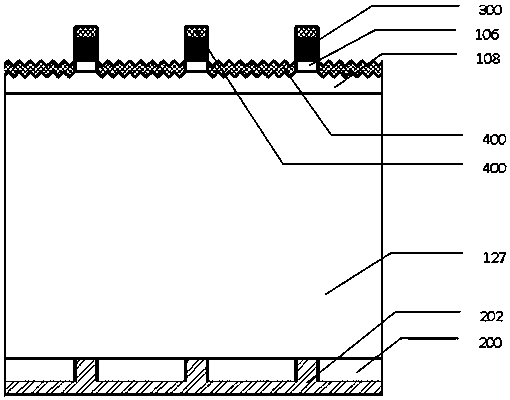

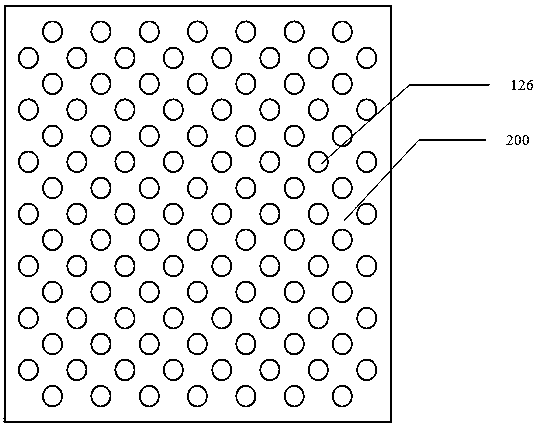

[0090]In step one, a GaAs buffer layer 102 and a sacrificial layer 104 are sequentially grown on the GaAs substrate 100 .

[0091] The double-junction battery structure is epitaxially grown on the GaAs substrate by MOCVD and other epitaxial equipment, and the pressure of the epitaxial reaction chamber is 76torr.

[0092] A. Firstly, the temperature of the GaAs substrate 100 is raised to 750° C. for 3 minutes to clean the GaAs substrate and form a step plane for epitaxial growth. Then lower the temperature to 600°C to start growing the cell epitaxial structure;

[0093] B. growing a 200nm GaAs buffer layer 102 on the surface of the N-type GaAs substrate 100;

[0094] C. A 30 nm AlAs sacrificial layer 104 is grown on the surface of the buffer layer 102 .

[0095] Step 2, forming an inverted growth GaAs top cell on the surface of the sacrificial layer 104

[0096] A. On the AlAs sacrificial layer 104, grow a 15nm P+ type GaAs front contact layer 106 with a doping concentration...

Embodiment 2

[0128] In step one, a GaAs buffer layer 102 and a sacrificial layer 104 are sequentially grown on the GaAs substrate 100 .

[0129] The double-junction battery structure is epitaxially grown on the GaAs substrate by MOCVD and other epitaxial equipment, and the pressure of the epitaxial reaction chamber is 100torr.

[0130]A. Firstly, the temperature of the GaAs substrate 100 is raised to 750° C. for 4 minutes to clean the GaAs substrate and form a step plane for epitaxial growth. Then lower the temperature to 650°C to start growing the cell epitaxial structure;

[0131] B. growing a 50nm GaAs buffer layer 102 on the surface of the GaAs substrate 100;

[0132] C. A 20 nm AlAs sacrificial layer 104 is grown on the surface of the buffer layer 102 .

[0133] Step 2, forming an inverted growth GaAs top cell on the surface of the sacrificial layer 104

[0134] A. On the AlAs sacrificial layer 104, grow a 10nm P+ type GaAs front contact layer 106 with a doping concentration of 2E ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com